A SIX-WHEELER FROM A FAMOUS WORKS.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

Details of a Thornycroft Rigid-frame Model to Carry Net Loads of 50 cwt. Over Good Roads and 30 cwt. Over Rough Tracks or Across Country.

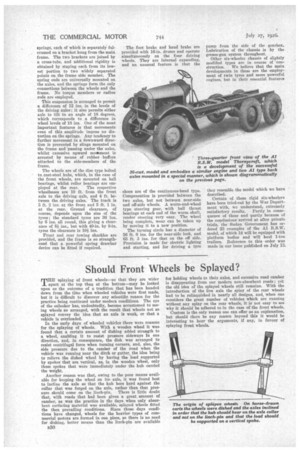

THERE have been few developments in the commercial-vehicle industry which have made such rapid progress as that concerning the tigid-frame sixwheeler. This type of vehicle posseases immense potentialities, and has 'proved itself so remarkably efficient, not onta on roads, but for cross-country trant port, that it bids fair to .outclass thecreeper-track machine, which, whilst being capable of giving excellent service in cross-country work, can hardly he looked upon as a satisfactory form of vehicle for extensive road use.

In this article we deal with the Thornycroft type Al R.S.W. chassis This is really a development of the wellknown 30-cwt. model, the power unit being similar, and having an R.A.C. rating of 22.5 h.p., the bore and stroke being 3i ins. and 5 ins, respectively. it will, however, develop 36 b.h.p. at 1,500 r.p.m. The four cylinders are cast en bloc and have a detachable head ; both inlet and exhaust valves are at the near side, and operated by a single camshaft. The crankshaft is carried in three diecast white-metal bearings, Whilst the bigend bearings consist of gun-metal shells with white-metal linings.

The circulation of the lubricating oil is effected by an oil pump carried in the sump and driven by skew gearing from the camshaft. A large gauze filter is fitted on the suction side; any dirt or carbon falls to the bottom of thecase and does not tend to choke the gauze, which, incidentally, can be removed and replaced through an inspection door. The oil under pressure passes througha tunnel cast in the side of the crankcase, and from this to the three main bearings, from which it penetrates through holes drilled in the crankshaft to the big,end bearings. A plunger-type indicator shows the driver that the pump is functioning.

Provision is made for thermo-siphonic circulation of the cooling water if the impeller-type pump be out of action, whilst cooling is assisted by the fan,

which serves to drive this impeller. The water is circulated through a gilled radiator of the cast-aluminium built-up type, which is mounted on cup-shaped rubber buffers and so insulated from vibration; a guard is provided to prevent (LiMag,o by collision, and a threeply screen can be fitted behind the radiator to regulate the cooling effect in•cold weather.

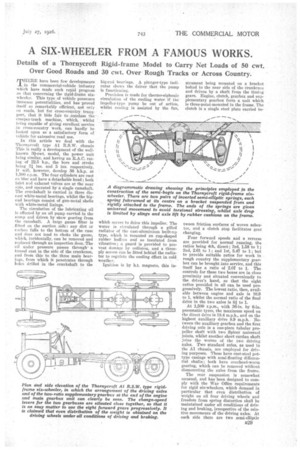

Ignition is by h.t. magneto, this in. strument being mounted on a bracket bolted to the near side of the erankcaee and driven by a shaft from the timing gears. Engine, clutch, gearbox and supplementary gearbox form a unit which is three-point-mounted in the frame. The clutch is a single steel plate carried be tween friction surfaces of woven asbestos, and a clutch stop facilitates gear changing.

Four forward speeds and a reverse are provided for normal running, the ratios being 4th, direct ; 3rd, 1.58 to 1; 2nd, 2.61 to 1; and 1st, 5.47 to 1' but to provide suitable ratios for work in rough country the supplementary gearbox can be brought into service, and this itself has a ratio of 2.07 to 1. The controls for these two boxes are in close proximity and situated conveniently to the driver's hand, so that the eight ratios provided in all can be used progressively. The lowest ratio, then, available between engine and axle is 10.9 to 1, whilst the normal ratio of the final drive in the two axles is 81 to 1.

At 1,500 r.p.m., with 36-in. by 6-in, pneumatic tyres, the maximum speed on the direct drive is 18.4 m.p.h., and on the highest auxiliary drive 8.9 m.p.h. Between the auxiliary gearbox and the first driving axle is a one-piece tubular propeller shaft with two Spicer universal joints, whilst another short cardan shaft joins the worms of the two driving axles. Two standard axles, as used in the Al chassis, are employed for driving purposes. These have cast-steel pottype casings with semi-floating differential shafts; both have overhead-worm gearing, which can be removed without dismounting the axles from the frame.

The rear suspension is somewhat unusual, and luta been designed to comply with the War Office requirements for rigid six-wheelers, which demand in particular that even distribution of weight on all four driving wheels and freedom from spring distortion shall be maintained under all conditions of driving and braking, irrespective of the relative movements of the driving axles. At each side there are two semi-elliptic springs, each of which is separately fulcrumed on a bracket hung from the main frame. The two brackets are joined by a cross-tube, and additional rigidity is obtained by staying each from its lowest portion to two widely separated points on the frame side member. The spring ends are universally mounted on the axles, and the springs form the only connections between the wheels and the frame. No torque members or radius rods are employed.

This suspension is arranged to permit a difference of 12 ins, in the levels of the driving axles; it also permits either axle to tilt to an angle of 18 degrees, which corresponds to a difference in wheel levels of 18 ins. One of the most important features is that movements even of this amplitude impose no distortion on the springs. Any tendency to further movement in a downward direction is prevented by slings mounted on the frame and 'passing under the axles, whilst excessive upward moment is arrested by means of rubber buffers attached to the side-members of the frame.

The wheels are of the disc type bolted to cast-steel hubs, which, in the case of the front wheels, are mounted on ball bearings, whilst roller bearings are em ployed at the rear. The respective wheelbases are 10 ft. from the front axle to the driving axle, and 4 ft. between the driving axles. The track is 5 ft. 2 ins. at the front and 5 ft. 1 in. at the rear. Ground clearance, of course, depends upon the size of the tyres; the standard tyres are 36 ins. by 6 ins. all round, this giving a clearance of 8i ins., but with 40-in. by 8-in. tyres the clearance is 101 ins.

Front and rear towing shackles are provided, and the frame is so strengthened that a powerful spring drawbar device can be fitted if required. •

The foot brake and hand brake are provided with 16-in, drums and operate simultaneously on the four driving• wheels. They are internal expanding, and an unusual feature is that the

shoes are of the continuous-band type. Compensation is provided between the two axles, but not between near-side and off-side wheels. A worm-and-wheel type steering gear, with ball thrust bearings at each end of the worm shaft, render steering very easy. The wheel being complete, wear can be taken up by moving it to a new position.

The turning circle has a diameter of 56 ft. 6 ins, for the near-side lock, and 63 ft. 3 ins, for that on the off side. Provision is made for electric lighting and starting, and for driving a tyre pump from the side of the gearbox. Lubrication of the chassis is by the grease-gun system throughout.

Other six-wheeler chassis of slightly modified types are in course of construction. We believe that the main developments in these are the employment of twin tyres and more powerful engines, but in their essential features they resemble the model which we have described.

Certain of these rigid .six-wheelers have been tried-out by the War Department with, we understand, extremely

satisfactory results. Partly in consequence of these and partly because of the conclusions arrived at after private trials, the Sudan Government has ordered 23 examples of the Al R.S.W. model, of which 18 will be equipped with platform bodies and will haul 1-ton trailers. Reference to this order was made in our issue published on July 13.