Rocking the boat

Page 27

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Already proving popular in the USA, the boat-tail addition is now attracting interest in Europe

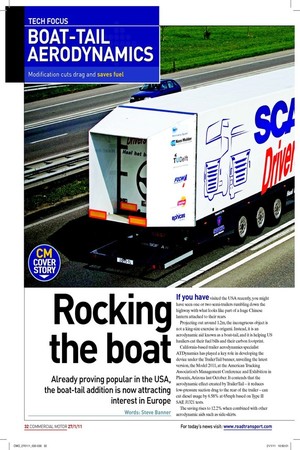

Words: Steve Banner E If you have visited the USA recently, you might

have seen one or two semi-trailers rumbling down the highway with what looks like part of a huge Chinese lantern attached to their rears.

Projecting out around 1.2m, the incongruous object is not a king-size exercise in origami. Instead, it is an aerodynamic aid known as a boat-tail, and it is helping US hauliers cut their fuel bills and their carbon footprint.

California-based trailer aerodynamics specialist ATDynamics has played a key role in developing the device under the TrailerTail banner, unveiling the latest version, the Model 2011, at the American Trucking Association’s Management Conference and Exhibition in Phoenix, Arizona last October. It contends that the aerodynamic effect created by TrailerTail – it reduces low-pressure suction drag to the rear of the trailer – can cut diesel usage by 6.58% at 65mph based on Type II SAE J1321 tests.

The saving rises to 12.2% when combined with other aerodynamic aids such as side-skirts. Attaching a large fairing to the rear of a trailer has its drawbacks, but a big weight increase is not one of them. TrailerTail is made from light and lexible thermoplastic composite materials and tips the scales at less than 80kg.

Installation

It is designed to be installed by two people in two hours, but Mesilla Valley, which is trialling TrailerTail, says experience in itting the package itself has enabled it to cut the time taken signiicantly.

Rather more of a concern than weight or itting time is the risk of damage to the device if the trailer is reversed up to a loading dock. There is no need to worry, says ATDynamics chief executive oficer Andrew F Smith: TrailerTail’s panels fold up automatically in under six seconds as the rear doors are swung open and end up lush against them.

If the driver forgets, then TrailerTail will gently collapse in on itself the minute it touches the dock.

Once loading/unloading has been completed and the back doors are shut, the panels automatically re-deploy. “We’re now developing a version that will work in conjunction with a roller-shutter door,” he says.

What about the risk that the fairing will swing out and clout street furniture or a hapless motorcyclist if the driver has to execute a tight turn? “Trucks equipped with TrailerTail have now covered thousands and thousands of miles without a single incident of that sort being reported,” Smith replies.

Repair costs

ATDynamics estimates that over some three million miles of highway driving, TrailerTail repair costs have totalled no more than $150 – less than £100. The irm says incremental beneits include a reduction in spray, and an improvement in trailer stability, with less sway at the rear.

A TrailerTail costs $2,400 at list price, but high-mileage users will ind that it pays for itself in less than a year, says the company. The words ‘high mileage’ are crucial: the device operates to best effect on long motorway runs, not on short-haul stop-start work.

Working in conjunction with Goodyear engineers and employing trucks sourced from Walmart, ATDynamics has used the tyremaker’s test facilities in San Angelo, Texas to demonstrate that TrailerTail can bring the fuel-saving beneits it says it does, says Smith.

Type II SAE JI321 tests have been carried out in conjunction with Canadian research institute FP Innovations, using the Energotest programme run by its PIT operation, and Canadian haulier Robert Transport.

“We went through hundreds of different designs before we came up with the current one,” Smith adds.

Boat-tails have been tested in Europe under the auspices of PART, the Platform for Aerodynamic Road Transport.

With Delft University of Technology – TU Delft – in the Netherlands acting as its secretariat, it is a publicprivate alliance of vehicle manufacturers, transport operators and researchers. Members include Dutch aerodynamics specialist Ephicas and SDC Trailers, and its ambition is to help achieve a 20% cut in the use of fuel and in CO2 emissions.

PART’s test programme involved running an artic for a year with boat-tails of varying lengths – 1m, 1.5m and 2m – positioned at different angles, then for a year without a boat-tail at all.

“The improved aerodynamics resulted in a reduction in fuel consumption, depending on the length of the boat-tail, of up to 7.5%,” says the organisation. “The optimum length proved to be 2m.” In addition, TU Delft has tested boat-tails in a wind tunnel, says chief design engineer at SDC’s Mansield operation Tony Sturgess. “It found that a 12% reduction

in drag could be achieved, which it equates to a possible ▲ Anders Gustavsson, 6% fuel saving,” he adds. MD of the Scania

Aerodynamic sideskirts

PART has been involved in testing aerodynamic trailer sideskirts developed by Ephicas using aerospace technology; Ephicas evolved from TU Delft’s Faculty of Aerospace Engineering. The results showed that Ephicas SideWings could help achieve an average cut in diesel consumption of more than 9%.

A STAS MF Streamline walking-loor trailer equipped with them was tested by Commercial Motor at the MIRA Proving Ground in Bedfordshire (CM 29 April 2010), resulting in a 5.8% overall saving rising to 8.1% at 89km/h.

Ephicas will start selling SideWings in the UK during the course of the next few months and is now working with TU Delft to develop a boat-tail ine-tuned to European operating conditions, says CEO Hessel Jongebreur. “We started with 10 possible designs and we’ve been busy narrowing them down,” he says. “We’re hoping to test a modiied TrailerTail in Europe in 2011,” he continues. “We’re looking at testing an inlatable boat-tail too, as well as a rear-mounted 3D spoiler and an active-low system that uses blowers.

“With the latter approach, there shouldn’t be the need to add too much additional length to the trailer.” The inlatable boat-tails were trialled in the US. “By next July/August we’ll have narrowed the number of solutions we’re exploring to just two,” he says.

While 2m might be the best bet in terms of cutting fuel consumption, Jongebreur is concerned that it might be dificult to fold away a boat-tail of that length.

“From a practical viewpoint therefore, the optimum length is probably 1.3m to 1.5m,” he observes. “If you go shorter, then you lessen the effect.” There is one key drawback, however. Aerodynamic aid or not, in Europe the boat-tail is included in the overall maximum permitted length of a tractor unit/semi-trailer combination. Mount one on the back of a standard-length semi-trailer, and haul it onto the public highway with a standard-length tractor unit without special permission from the authorities and you will be committing an offence.

By contrast, non-cargo-carrying rear-mounted aerodynamic devices up to 5ft-long enjoy an exemption from overall length limits in the US under federal regulations.

The exemption applies to vehicles travelling on the country’s oficially designated national network for trucks, totalling more than 200,000 miles countrywide, plus “reasonable access routes” leading to the network.

It does not apply, however, to devices rigid enough to cause damage to a vehicle that collides with the rear of the trailer or that obscure the rear lights, indicators, marker lamps, conspicuity markings or hazardous materials placards.

Changing attitudes

However, there are signs that attitudes are changing on this side of the Atlantic, with a recently introduced EU proposal to amend Directive 97/27 EC to permit semitrailers to be equipped with a rear air-delector that increases the length of a standard combination by 30cm. That is equivalent to the extra length allowed under 97/27 EC if a tail-lift or another piece of loading equipment has to be accommodated.

In response, the Scania Transport Laboratory has started practical tests in Sweden and Denmark of a 30cm plastic and aluminium boat-tail and believes it could cut diesel usage by up to 2%. That corresponds to an annual saving of 1,200 litres of diesel and three tonnes of CO2 if the truck concerned covers 200,000km annually. Weighing about 15kg, the boat-tail is attached to an otherwisestandard tri-axle semi-trailer.

“Our laboratory trucks travel 360,000km each annually and consume fuel at an average 26lit/100km. A 2% reduction would represent an annual saving of almost 1,900 litres of diesel and ive tonnes of CO2 per vehicle,”

says MD Anders Gustavsson. “That sort of improvement is equivalent to the results of several years of engine and chassis development work.” Gustavsson hopes European trailer makers will start offering their products with a suitably designed integrated boat-tail if legislation permits.

“It’s a simple technical solution that does not encroach on cargo space, can be retroitted, and could quickly help to reduce transport costs and environmental impact,” he says.

“A 30cm boat-tail will help, but it won’t have enough of an effect,” says Jongebreur. “It needs to be longer.” He is convinced that with further research the industry will be able to persuade regulators to permit boat-tails in excess of 30cm given their proven ability to cut emissions and shrink carbon footprints.

While British trailer makers view boat-tails with interest, many of them question how practical they will be and how well they will withstand damage in arduous UK operating conditions, despite their apparent durability in the US.

“We did a lot of work on the use of fairings on the rear of trailers about eight or nine years ago – in fact we spent millions on it – only to ind that they got torn off within

two weeks of being in service,” says Don-Bur marketing ▼ Despite its size, manager Richard Owens. “They make sense aerodynamiTrailerTail weighs cally, although I suspect that the impact of a 30cm in at less than 80kg

boat-tail will be neither here nor there, but the worry is that they may not stand the test of time.

“I’m also concerned that if boat-tails are permitted, then all sorts of people will start jumping on the bandwagon and producing them without testing them irst to see if their chosen designs actually work,” he adds.

Fuel savings

Trailer makers also stress that while the fuel saving that can be garnered would undoubtedly be worth having given the rising price of diesel, a boat-tailed trailer would not be able to carry any more goods.

They go on to highlight the fuel savings that can be made by operators who adopt the sort of aerodynamic modiications companies such as Cartwright Group have already made and that do not require changes to the rules governing overall length.

Cartwright points out that its Cheetah Fastback trailer offers a potential 10% fuel saving compared with what’s on offer from a conventional box-bodied trailer thanks to its curved rear roof, its front aerofoil and its wheel covers, among other features.

Don-Bur highlights the ability of its Teardrop trailer to return an average fuel saving of 11.3%. With changes such as a new skirting system and rear frame design, Don-Bur hopes the MK2 will achieve a 15% average saving.

While not dismissing boat-tails – “the principle is absolutely correct” – Cartwright director Steven Cartwright contends that there is a strong case for using aerodynamic modiications to alter the length of the tractor unit rather than the trailer.

“If you’re going to do anything in this area then you should start with the block of lats at the front,” he suggests. His idea is to extend the unit forwards with an aerodynamically sculpted safety cell that would help protect the driver in a collision, as well as reducing fuel usage.

The result could look rather like an American bonneted truck – a change many trucking enthusiasts would doubtless welcome. ■