For DRIVERS, MECHANICS & FOREMEN.

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D. M. and F., "The Commercial Motor," 7-15, Rosebery Avenue, London, KC. 1.

To Contributors.

We wish to draw the attention of contributors to this page to the new conditions of payment as set out in the heading. We are often asked by readers to extend the space given to this feature, but we would rather encourage brevity so that a number of letters can be dealt with weekly. A suggestion which we will adopt is the payment of an extra fee of half a guinea to the sender of a letter which opens up a useful discussion in this page.

Lamps Alight.

On Saturday, January 31st, light your lamps at 5.14 in London, 5.5 in Edinburgh, 5.3 in Newcastle, 5.18 in Liverpool, 5.18 in Birmingham, 5.24 in Bristol, and 6.1 in Dublin.

Reamering Wheel Bushes.

The sender of the following communication has been awarded the extra payment of 5s. this week,.

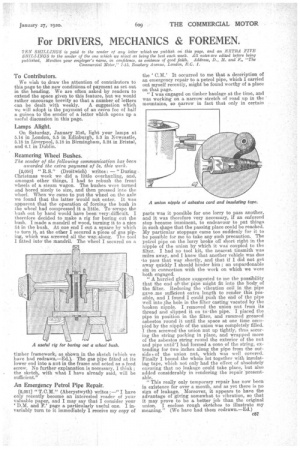

[2,050] " R.S." (Droitwich) writes: — "During Christmas week we did a little overhauling, and, amongst other things, I had to rehush the front wheels of a steam wagon. The bushes were turned and bored nicely to size, and then pressed into the wheel. When we came to put the wheel on the axle we found that the latter would not enter. It was apparent that the operation of forcing the bush in the wheel had compressed it a little. To scrapethe bush out by hand would have been verytdifficult. I therefore decided to make a, rig for boring out the bush. I made a mandril of wood, turning it to a nice fit in the bush. At one end I out a square by which to turn it, at the other I secured a piece of gas piping, which was screwed all the way, along. The tool I fitted into. the mandril. The wheel I secured on a timber framework, as shown in the sketch (which we have had redrawn.—Ed.). The gas pipe fitted at its lower end into a nut in the frame and acted as a, feed screw. No further explanation is necessary, I think ; the sketch, with what I have already said, will be sufficient."

An Emergency Petrol Pipe Repair.

[2,051] " (Aberystwyth) writes :—" I have only recently become an interested reader of your valuable paper, and I may say that I consider your D.M. and F.' page a particularly useful one. I invariably turn to it immediately I receive my copy of

the C.M.' It occurred to me that a deacription of an emergency repair to a petrol pipe, which I carried out myself recently, might be found worthy of a place on that page. " I was engaged on timber haulage at the time, and was working on a, narrow stretch of road up in the mountains, so narrow in fact that only in certain parts was it possible for one lorry to pass another, and it was therefore very necessary, if an enforced stop became imminent, to endeavour to put things in such sjaape that the passing place could be reached. My particular stoppage came too suddenly for it to be possible for me to take any such precaution. The petrol pipe on the lorry broke off short right in the nipple of the union by which it waii coupled to the filter. I had no tool kit, the nearest tinsmith was miles away, and I knew that another vehicle was due .to pass that way shortly, and that if I did not get away quickly I should hinder him ; an unpardonable sin in connection with the work on which we were both engaged.

"A hurried glance suggested to me the possibility that the end of, the' pipe might fit into the body of

the filter. Reducing the vibration coil in the pipe gave me sufficient extra length to render this possible, and I found I could push the end of the pipe well into the hole in the filter casting vacated by the broken nipple. I removed the union nut from its thread and slipped it on to 'the pipe. I placed the pipe in position in the filter, and rammed greased asbestos round it until the space at one time occupied by the nipple of the union was completely filled. I then screwed the union nut up tightly, thus secur ing the string packing in place, and wrapped more of the asbestos string round the exterior of the nut and pipe untill had formed a cone of the string, extending for two inches along the pipe from the outside s of the union nut, which was well covered. Finally I bound the whole lot together with insulating tape, which not only had the effect of absolutely ensuring that no leakage could take place, but also added considerably in rendering the repair presentable.

"This really only temporary repair has now been in existence for over a month, and as yet there is no sign of leakage.Moreover, it appears to have the advantage of giving somewhat to vibration, so that it may prove to be a better job than the original union. I enclose rough sketches to illustrate my meaning." (We have had them redrawn.—Ed.)