Oxy-Acetylene Welding.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

A New Method of Construction which the Autogenous Method of Welding has Rendered Possible.

In " THE COMMERCIAL MOTOR " of the gth of May last, we gave a few particulars of the autogenous system of welding, by means of the Oxy-Acetylene blowpipe. The acetylene is supplied (in the " dissolved " state) in steel cylinders by The Acetylene illuminating Company, Lithited, of 268-27o, South Lambeth Road, S.W., and, by this process of welding, it is possible to make engine crankshafts out of sheet steel, a method of construction which gives an extremely light shaft, and one which, in large quantities, can be very cheaply produced.

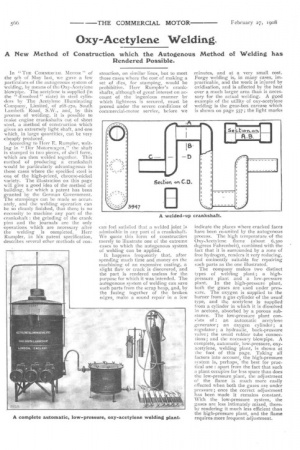

According to Herr F. Rumpler, writing in " Di2r Motorwagen," the shaft is stamped in two pieces, of shell form, which are then welded together. This method of producing a crankshaft would be particularly advantageous in those cases where the specified steel is one of the high-priced, chrome-nickel variety. The illustration on this page will give a good idea of the method of building, for which a paterit has been granted by the German Government. The stampings can be made so accurately, and the welding operation can he so cleanly finished, that there is no necessity to machine any part of the crankshaft : the grinding of the crank pins and the journals are the only operations which are necessary after the welding is completed. Herr Rumpler, in his patent specification, describes several other methods of eon_ struction, on similar lines, but to meet those cases where the cost of making a set of dies, for stamping, would be prohibitive. IIerr Rurnpler's crankshafts, although of great interest on account of the ingenious manner by which lightness is secured, must be proved under the severe conditions of commercial-motor service, before we

can feel satisfied that a welded joint is admissible in any part of a crankshaft. We quote this form of construction merely to illustrate one of the extreme cases to which the autogenous system of welding can be applied.

It happens frequently that, after spending much time and money on the machining of an expensive casting, a slight flaw or crack is discovered, and the part is rendered useless for the purpose for which it was intended. The autogenous system of welding can save such parts from the scrap heap, and, by the fusing together of the broken edges, make a sound repair in a few minutes, and at a very small cost. Forge welding is, in many cases, impracticable, and the work is injured by oxidisation, and is affected by the heat over a much larger area than is necessary for the actual welding. A good example of the utility of oxy-acetylene welding is the gear-box carcase which is shown on page 557; the light marks indicate the places where cracked faces have been re-united by the autogenous process. The high temperature of the Oxy-Acetylene flame (about 6,300 degrees Fahrenheit), combined with the fact that it is surrounded by a zone of free hydrogen, renders it very reducing, and eminently suitable for repairing such parts as the one illustrated.

The company makes two distinct types of welding plant ; a highpressure plant and a low-pressure plant. In the high-pressure plant, both the gases are used under pressure. The oxygen is supplied to the burner from a gas cylinder of the usual type, and the acetylene is supplied from a cylinder in which it is dissolved in acetone, absorbed by a porous substance. The low-pressure plant consists of : an automatic acetylene generator; an oxygen cylinder ; a regulator; a hydraulic, back-pressure valve ; the usual rubber tube connections; and the necessary blowpipe. A complete, automatic, low-pressure, oxyacetylene, welding plant, is shown at the foot of this page. Taking all factors into account, the high-pressure system is, perhaps, the best for practical use : apart from the fact that such a plant occupies far less space than does the low-pressure plant, the adjustment of the flame is much more easily effected when both the gases are under pressure ; once the correct adjustment has been made it remains constant. With the low-pressure system, the gases arc less intimately mixed, thereby rendering it much less efficient than the high-pressure plant, and the flame requires more frequent adjustment.