ROAD DAMAGE THE WAY OUT.

Page 19

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Positive Proof is Provided by Official Tests, here Described, that Road Wear can be Materially Reduced by Employing More Wheels and Pneumatic Tyres.

WHAT IS certainly not known with regard to the relation between the road and the heavy motor vehicle is 'as to exactly what forces the roan is subjected when a loaded vehicle passes over it. That knowledge is now being extensively sought by road engineers, and they have a very useful contribution in the shape of a report published earlier this year from the Bureau of Public Roads, a section of the United States Department of Agriculture, the work of preparation having been carried out by the Division of Tests and Research.

Whon the United States decided to throwits weight into the scale with the Allies, the rapidly growing use of the American railways for military purposes caused a general breakdown of the existing longdistance transport methods used in commerce, and, so far as goods that had no relation to war work were concerned, the roads had to be employed, and motor vehicles became the conveyors of much of the domestic traffic of that country. The weak link, naturally, proved to be the roads, for they had been built primarily for horsed vehicles. Many of them being of macadam, they went to pieces, and, on examination, it was found that all-round destruction of the substructure of the road was occurring. The result of all the war travel was that the roads were

ultimately in a very bad shape, and the public began to protest. This got the Government interested, and resulted in sanction being given for a thorough investigation of the question.

Ideas quickly centred upon the. matter of impact as being the root of the trouble, for not only was there attrition of the surface, but there was real deformation of the substructure. So it was decided to ascertain what the impact of a motor vehicle wheel amounted to, so that, with this knowledge, the roads could be built to stand the impact, or laws could be enacted to limit the loads to the point where the impact would not be destructive.

It was felt that the type of tyre would play a very important part in this matter, so a number of types were used in the experiments consisting of the following:— Solids:

12 ins, wide, slightly worn..

10 ins, wide, slightly worn.

10 ins, wide, new.

7iins, wide, new. 40 ins. by 6 ins., dual, worn to 2 ins. thick. 36 ins. by 5 ins., dual, worn to1-7ins. thick. 36 ins. by 4 ins., dual, slightly worn.

36 ins. by 5 ins., dual, new. 36 ins. by 4 ins., dual, new. 40 ins. by 6 ins., dual, new. 40 ins, by 6 ins., dual, slightly worn. 40 ins. by 6 ins., dual, worn to 1 8-10ths in. thick. 40 ins. by 6 ins., dual, worn to 1i ins. thick. 30 ins, by 7 ins., grooved, worn. 30 ins. by 8 ins., grooved, new. 40 ins. by 10 ins., grooved, new, diamond tread, 36 ins. by 10 ins., worn to in. 36 ins. by 8 ins., worn to in.

40 ins. by 10 ins., worn to 1 3-10ths in. .

Pneumatic : 44 ins. by 10 ins, cord tyre inflated to 140 lb. 40 ins. by 8 ins. cord tyre inflated to 120 lb. 42 ins. by 9 ins. cord tyro inflated to 120 lb.

Cushion 36 ins. by 5 ins., dual, new.

The worn solid tyres were included in the tests because it was expected that, when thin or worn, even a very wide tyre will produce very high impact forces. The general result of these experiments, which we propose to describe, was the conclusion that impact depends largely upon the kind and condition of the tyre. The pneumatic, as would be expected, offers e greatest influence in reducing impact forces, and, with its use, the impact increases only very slightly with the speed of the vehicle, which would have an important bearing upon any proposals to grant higher speed privileges to vehicles shod with tyres which reduced the ill-effect of speed. Cushion tyres, that is tyres having a degree of softness and deflection between solids and pneumatics, offer corresponding advantages in reducing impact. It was found that, although heavy unsprung weight may give higher impact than lighter unsprung weight, it could not be said that this is the major controlling factor. Again, it was not determined whether lightweight high-speed vehicles or heavy slow-moving vehicles produced the most destructive effect upon the roads.

What was brought out most clearly by the tests was the fact 'that impact may be as high as seven times the static load on one rear wheel when a solid tyred vehicle strike's a one-inch.. obstruction at 16 miles an hour, the average value being about four times. For pneumatic tyres, the maximum impact value is probably not more than i times the load. on one rear wheel, and average value being 1i times the load.

This last-mentioned fact is clearly shown in our first diagram, at the head of which are set out the types of vehicles and their tyres, and the gross weight of each vehicle with its paying load. Below are details of the rear wheel weights, namely, the unsprung, the sprung, and the total, and below these come the impact forces, these latter also being expremed in diagrammatic form. The relation of the static load to the impact force is much the lowest in the case of the pneumatic-tyred six-wheeler, the five-tonneron large pneumatic& (12 ins, diameter on rear wheels means some tyre!) being next followed by the twoetonner, also on pneumatics. The impact force of the two-tonner on 4 in. solids will be seen to be extremely high.

The manner of conducting the tests has already been referred to in The Commercial Motor, but not in the detail into which we are now able to go. Two methods for determining' the. value Of impact were devised : .(a) by receiving the impact on some material the•deformation of which would be proportional to the force applied and by. comparing the deformation with that produced by a steadily applied or static force, and (b) by determining autographically the velocity and maximum deceleration of the mass when it strikes the resisting body.

The first method is the one employed for the tests referred to in this article, the material chosen to receive the impact being round copper rod, in. .iii diameter and machined to in. lengths., pieces were heat treated to secure uniform ity of stress resistance, that is, to make them all of even softness.

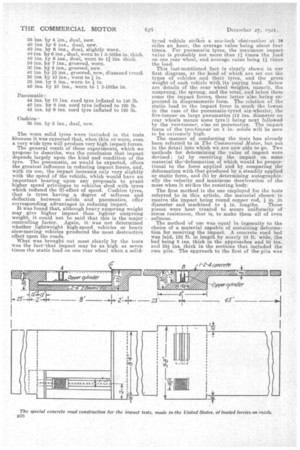

The method of use was equal in ingenuity to the choice of a material capable of sustaining deformation for receiving the impact. A concrete road bed was laid, '125 ft. in length by nearly 10 ft. wide, the bed being 8 ins, thick in the approaches and 30 ins. and 33-iins, thick in the sections that included the ram pits. The approach to the first of the. pits was

65 ft. long, and in the first ram pit was secured a cylinder, mouth upwards, in which fitted the plunger (B) (see the diagram showing the general arrangement), the head of which was flush with the road surface. Below the bottom face of the plunger would be placed the in. length of copper rod already referred to. Bolted to the plunger head would be a strip of hard wood 4 ins, wide and 16 ins. long, different thicknesses, namely, in., in., in., 1 in., 2 ins.' 3 ins., and, in the ease of pneumatic tyres, 4 ins, being used.

The impact of only the left rear wheel was measured, a bridge loch* placed over each plunger head to protect it from the front wheel, the bridge being jerked out of the way so soon as the front wheel had passed over it. . . The second ram (A) was placed in a pit commencing 25 ft. from the first ram pit. This pit held a jack or plunger similar to the other, but it was mounted on beams that would allow it to be moved to a position in the pit where it was found by experiment that the wheel of the vehicle would alight, after dropping off the drop-edge (E) (see diagram). The ram (B) would thus be used for ascertaining the impact force upon an obstruction, and the ram (A) for the force set up when a wheel dropped into a depression. Owing to the fact that the copper cylinder acts as a cushion, thus serving to reduce the value of the impact, and also that, under impact, it does not measure force alone, but measures work, this method of determination shows approximately the average force of impact ; the maximum value of the impact force may be nearly twice as great. The results plotted out on a chart, however, are accurate enough from the point of view of comparison, if correction be made for this cushioning effect of the copper cylinder, the necessary correction being worked out for each in. of fall.

Throughout the whole series of tests it became clear that the impact curves in the case of the large pneumatic (8 ins, diameter and upwards) were as neacrly fiat as possible, despite the increase of speed, whereas the curves in the case of dual cushions, wide solids, and dual solids rose materially higher. In one series of tesls with a two-tonner carrying a load of 2,000 lb. and made to drop 2 ins, on to lack (A), the impact of a 40 ins. by 8 ins. pneumatic inflated to 120 lb. rose from 4,200 lb. at 5im.p.h. to nearly 8,000 lb. at 21 m.p.h. ; a 42 ins. by 9 ins.. pneumatic inflated to 139 lb. gave an impact figure of 5,200 lb. at al m.p.h. and of 7,000 lb. at 1722 m.p.h. In the me of the dual cushion the figures were 5,500 lb. at 6 m.p.h., rising to 11,500 lb. at 12ti in.p.b. where they remained constant up to 174 m.p.h. The S in. rib-tread solid started at 6,500 lb. at 3 m.p.h. and rose to 16,700 lb. at 11 m.p.h., whilst the dual solid tyre. started at nearly 7,000 lb. at 3 m.p.h. and rose to 19,400 lb. at 17'1 m.p.h.

These are striking figures and show that not only is it advantageous to reduce the weight of the static load per wheel and to carry the weight on pneumatics, but that the speed may be allowed to rise, in the case of a load so carried, to an infinitely higher level than if any other method be adopted, with an extremely small increase on impact.

The construction of a six-wheeled vehicle, such as had been consistently advocated in the columns of The Commercial Motor, means less unsprung weight in the ease of a vehicle weighing, gross, 28,700 lb. and carrying a load of 17,500 lb. than in the case of one with aegross weight of only 11,800 lb. and carrying a 4,000 lb. load on four wheels.

It is sometimes thought that width in a tyre (in the ca-se of solids) is a determining factor in the absorption of vibration and that the wearing down of a solid is not of such great importance in increasing vibration, because, automatically, the width increases with wear. But this is fallacious, because the resiliency of a solid tyre decreases rapidly as it wears. In the ease of the pneumatic, there is not much difference in resiliency arising from the effects of wear.

The net effect of these interesting tests would seem to be that pneumatic-tyred vehicles mounted upon more than four wheels should be allowed to travel at higher speeds than the four-wheeled solid-tyred vehicle, because, in their ease, higher speeds can be attained without any great increase of damage to the roads. Again, the multi-wheeled pneumatic-tyred vehicle should be allowed to carry heavier loads at these higher speeds. Then comes the question of taxation. As weight 'determines carrying capacity, taxation should be devised on a scale accordinwto weight, as at present, but modified by the cushioning effect of the superior type of tyre. As the pneumatic does not materially increase its impact with speed, it should bring to its user the benefit of substantial rebate. This would be in justice to the owner who was prepared to shoulder the • additional burden of the air tyre, the chief benefits of which would fall upon the road, the secondary benefits being to the vehicle (because of reduced maintenance charges), to the load (because of greater comfort in the case of passengers and greater immunity from damage in the case of goods), and to the owner (because of some saving in first cost and running costs, owing to the employment throughout the chassis of lighter components). There have, in the past few years, been enormous developments in the science of road building. Our ideas to-day are not what they were and vehicle design must move equally fast. Only by such means can the motor vehicle industry and the road transport industry make substantial progress against their great Competitors, the railway systems of the country.