/ Thoroughly practical is not perhaps the most flattering response

Page 24

Page 26

Page 27

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

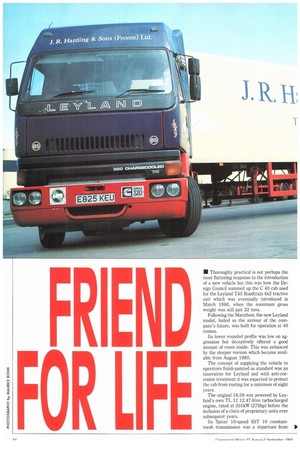

to the introduction of a new vehicle but this was how the Design Council summed up the C 40 cab used for the Leyland T45 Roadtrain 4x2 tractive unit which was eventually introduced in March 1980, when the maximum gross weight was still just 32 tons.

Following the Marathon, the new Leyland model, hailed as the saviour of the company's future, was built for operation at 40 tonnes.

Its lower rounded profile was low on aggression but deceptively offered a good amount of room inside. This was enhanced by the sleeper version which became available from August 1980.

The concept of supplying the vehicle to operators finish-painted as standard was an innovation for Leyland and with anti-corrosion treatment it was expected to protect the cab from rusting for a minimum of eight years.

The original 16.28 was powered by Leyland's own TL 12 12.47-litre turbocharged engine, rated at 201kW (270hp) before the inclusion of a chain of proprietary units over subsequent years.

Its Spicer 10-speed SST 10 constantmesh transmission was a departure from Leyland Trucks'

jp k 0 'IF, tradition but not wholly successful with RIdrivers as it tended to be noisy and uncertain in operation.

II EVOLUTION

The 4x2 16.28 was introduced first in daycab form and the sleeper version followed. Both the TL12 and Cummins 14-litre engine rated at 186kW (250hp) for the 16.25 and 216kW (290hp) an option for the 16.28, were available with the day-cab, but further engines were introduced on sleepercab models. The then Rolls Royce 265L 12-litre unit became available in mid-1981. The 6x2 twin-steer was introduced fitted with the Cummins 320 engine in June 1983.

Over the following years there was a succession of more powerful options from Cummins and Perkins culminating in the NTE 350 and Eagle 800 350 units. Cummins' lighter L10 offered an output of 250hp throughout 1986 and the 290hp version remained an option while Roadtrain models remain in production until October 1990. Over 10 years the range made use of 14 different engine options. The current equivalents, FT and FTG 80.330, now take the 11.6-litre Oaf engine and Oaf single reduction axle rated at 11 tonnes which can now be specified with air suspension on the 4x2.

• OPERATORS

At Frome, Somerset, Ray Harding is engineering director for the controlled temperature transport and storage company he runs with his four brothers. They have 50 trucks which have to be maintained along with the cooling equipment for three warehouses. Up to 80% of the fleet are articulated vehicles and 16 of the tractive units are 20-32 6x2 Leyland Roadtrains. Early models, A-C registrations, were fitted with Spicer gearboxes but later E and F models were specified with Eaton TwinSplitter transmissions. "We had a fair bit of trouble with the Spicer box," he told us, "two of them blew up. We asked Leyland for the Eaton box and although the drivers like them they haven't been totally trouble free. Some of the solenoid valves on top of the box needed replacing at £70 to £80 a time, Some go on for ever and others may last as little as six months.

"On early models the radiators split at the corner. They didn't stand up to the chassis flexing, but the mountings are better now. We keep our vehicles for about seven years and cover more than 55,000 miles a year so we are likely to pick up on most of the faults sooner or later.

"The brake foot valve problem went away after Leyland carried out a modification. Alternators have been troublesome. They only last 18 months to two years and the batteries don't have sufficient capacity either. If the driver uses the electrics much on an overnight then he could have problems starting in the morning. Our biggest concern with the truck is the rear axle. The hub reduction is not man enough for the job. Drivers complain about the noise, but even when it's been repaired that doesn't go away. Premature failures include splitting fuel tanks and exhaust pipes which crack around the flanges. Bushes and pins in the driver's suspension seat wear out in 10 months. That sort of thing should last the life of the vehicle."

Harding employs six vehicle fitters and a fridge fitter who service the vehicles every 6,000 miles. "It's not all bad. They give us between 6.92 and 7,22mpg. The ones with the Eaton boxes give the better fuel consumption. The brakes give exceptional wear and tyre life has been excellent.

The Interstate cab is spacious which pleases the drivers and because there has to be six tonnes on the drive axle before weight transfer to the second steer we've never had a traction problem.

"Cab panels rust," says Harding, "and if allowed to go unattended the box section, which the tilting ram is attached to, will buckle."

We asked if he would continue to replace Roadtrains with the current model. "Back-up nationwide has been good but we are working towards an all-Scania fleet. The Leyland's steel suspension gives a harsh ride by comparison. We are now running on six axles and five of them are air-suspended. They are also giving us up to 8.7mpg,' says Harding.

Tony Rosser, engineering director for BRT in Cardiff, operates 25 vehicles. Most are Leyland Oafs and include three Roadtrains and three of the current 80 series tractive units which are coupled to tank semi-trailers used for chemicals and powders.

"Our 4x2 has a Perkins/Spicer driveline and the two 6x2s are fitted with Cummins engines and Eaton box. The Perkins are best of all on fuel they give 8mpg where as. we only get 7mpg with the Currunins," says Rosser.

"Servicing is done once a month or at 10,000km whichever is sooner and we keep them to the death. We use a high-grade oil and with a high filtration by-pass filter it lasts for 50,000 miles. We have done this for the past four years and had no problems. The savings are about £500 a year for each truck. The price you pay for a secondhand Road train is low, they are light so for anyone starting out they must be a good buy; and the back up is good."

Rosser doesn't like the Spicer box and confirmed the „, problem with the planetary gears in the axle's hub. "The steel suspension is hard and if they had offered air we would have taken it. We fit 12.00s on the front axle — they wear better — and it means the whole fleet is on the same sized tyre except the later ones which use 295/80s.

"We paint our cabs every two years so cab rust is not a problem. Other trucks have a better image and so they may not be the last thing for the driver but if you want to make a profit they are a good truck. We've been very pleased with ours and plan to stay with Leyland Daf with the 80 series as well as the 95 series," says Rosser.

Ray Cecil's father started in transport carrying miners to the pithead in the late 20s. Today with son Geoff the firm operates 19 vehicles operating out of premises overlooking the Forest of Dean near Chepstow. The 12 Roadtrains include the last two restcab models to be registered, which were specified with Perkins 325 engines. Running up to 150,000km a year these vehicles are returning up to 9.5mpg on general haulage while the 320 Cummins were giving 8.5 and the 290s around 7mpg, Geoff told us.

"We haven't had the Perkins engines long enough to tell how well they last but the Cummins engines are no trouble. We get the injectors set every nine months and they go on and on. We've just rebuilt a 290 after 753,000 miles and it's good for as much again," says Cecil.

The Spicer gearbox lasted almost 600,000 miles. "We are having a lot of trouble with alternators at the moment but radiators are the biggest downfall. They leak around the header tank and the cores which need silver soldering to stop it happening again," he says.

Geoff is a trained toolmaker and has found his own solution to the hub reduction problem. "We machine the sun gear and press on a ring to replace the worn area. With spacers between the planetary gears and the top-hat section, it's a modification which lasts up to 500,000 miles and costs a fraction of the cost of a replacement. We keep them all their life so we want repairs to be permanent," says Geoff.

"Since the recession we have been looking at new vehicles because the prices are so low. Leyland back-up has been very good. We had a gearbox blow up in Ghent. They flew us out a new one the next day, I think it's often a matter of getting hold of the right person. We will probably move up to the 95 in time," Cecil concluded,

• DEALERS

Arlington Mackworth Truck Centre is Leyland Daf s largest used-truck dealer. "To gain Leyland Daf approval we have to meet certain standards and agree to carry a minimum stock of eight vehicles," Paul Johnstone told CM. "We are in contact with over 20 dealers in the scheme so the pool of vehicles available at any one time is quite large. We have 35 used trucks on this site alone and would like to have twice the number but as quick as we find good stock we are selling them.

We are sourcing from large fleets and to a lesser extent from auctions. Distressed sales are not often a good buy as the company may not have had the money to maintain the vehicle properly. We carry out what we call a P inspection which is the equivalent of a pre-MoT inspection and includes 115 checks," says Johnstone.

"At the point of sale all the faults are put right. The inspection check list is available to the purchaser so that he can see what needed attention. Our workshops are accredited to BS5750 so they know the work is carried out to a recognised standard," says Johnstone. "We are normally looking at vehicles up to five years old which we underwrite with six months premium cover. The main selling point on the Road train is the engine but we haven't lost a sale because of the gearbox. A typical 1989 F-registered 340hp Cummins-engined 6x2 with about 350,000km on the clock will cost £11,750."

We mentioned the faults that operators had pointed out to us. It appears that Leyland Daf has only belatedly solved the axle problem by turning to a Daf axle for the replacement range.

There is no change with the cab but we are assured that if action is taken when the rust first appears it can be held in check.

Ian McShannon and Derek Beatham started up UK Plant and Commercial at Wigan at the start of the year. On the plant side they sell a lot of their secondhand stock into Africa. On the vehicle front they specialise in tractive units and trailers and manage to export some of these as well. "The Roadtrain is in demand with the TL12 engine," says Beatham, an ex-operator.

"The Roadtrain sells well in this area with the Cummins and TwinSplitter driveline and the 6x2s are more popular than the twoaxle units. The price makes them popular with the owner-driver. If it's low–enough they don't need to get finance. The standard sleeper cab is a bit small and the rust can be a problem if it gets a hold. It's not a cab that I would want to sleep out in five nights a week. We would be looking for about £12,000 for a low mileage F-registered 6x2," says Beatham.

• SUMMARY

The Road train is not without its faults — many are relatively minor and occur over an indeterminate period but others, like the hub reduction axle, are more serious and expensive to rectify.

While Leyland put its house in order as far as a back-up support was concerned it remains an anomaly that obvious design faults were not addressed during the same period.

This does not, however, affect the Roadtrain's popularity. Secondhand values make it a good prospect and the choice of engines make it suitable for a wide range of applications.

1=1 by Bill Brock