FORD TRANSIT

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

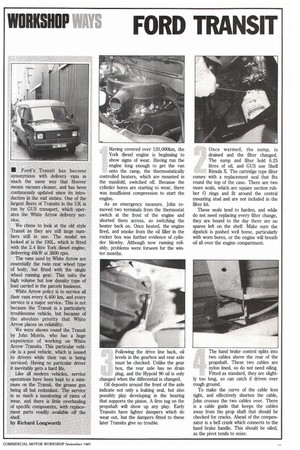

• Ford's Transit has become synonymous with delivery vans in much the same way that Hoover means vacuum cleaner, and has been continuously updated since its introduction in the mid sixties. One of the largest fleets of Transits in the UK is run by GUS transport, which operates the White Arrow delivery service.

We chose to look at the old style Transit as they are still large numbers still in use. The model we looked at is the 100L, which is fitted with the 2.4 litre York diesel engine, delivering 46kW at 3600 rpm.

The vans used by White Arrow are essentially the twin rear wheel type of body, but fitted with the single wheel running gear. This suits the high volume but low density type of load carried in the parcels business.

White Arrow policy is to service all their vans every 6,400 km, and every service is a major service. This is not because the Transit is a particularly troublesome vehicle, but because of the absolute priority that White Arrow places on reliability.

We were shown round the Transit by John Morris, who has a huge experience of working on White Arrow Transits. This particular vehicle is a pool vehicle, which is issued to drivers while their van is being serviced. Having no particular driver it inevitably gets a hard life.

Like all modern vehicles, service operations have been kept to a minimum on the Transit, the grease gun being all but redundant. The service is as much a monitoring of rates of wear, and there is little overhauling of specific components, with replacement parts readily available off the shelf.

by Richard Longworth

Having covered over 120,000km, the York diesel engine is beginning to show signs of wear. Having run the

engine long enough to get the van

onto the ramp, the thermostatically controlled heaters, which are mounted in the manifold, switched off. Because the cylinder bores are starting to wear, there was insufficient compression to start the engine.

As an emergency measure, John removed two terminals from the thermostat switch at the front of the engine and shorted them across, so switching the heater back on. Once heated, the engine fired, and smoke from the oil filler in the rocker box was further evidence of cylinder blowby. Although now running reliably, problems were forseen for the winter months.

Following the drive line back, oil levels in the gearbox and rear axle must be checked. Unlike the gear box, the rear axle has no drain plug, and the Hypoid 90 oil is only changed when the differential is changed.

Oil deposits around the front of the axle indicate not only a leaking seal, but also possibly play developing in the bearing that supports the pinion. A firm tug on the propshaft will show up any play. Early Transits have lighter dampers which do wear out, but the dampers fitted to these later Transits give no trouble. Once warmed, the sump, is drained and the filter changed. The sump and filter hold 6.25 litres of oil, and GUS use Shell Rimula X. The cartridge type filter comes with a replacement seal that fits round the top of the case. There are two more seals, which are square section rubber 0 rings and fit around the central mounting stud and are not included in the filter kit.

These seals tend to harden, and while do not need replacing every filter change, they are bound to the day there are no spares left on the shelf. Make sure the dipstick is pushed well home, particularly with worn bores, or the engine will breath oil all over the engine compartment.

The hand brake control splits into two cables above the rear of the propshaft. These two cables are nylon lined, so do not need oiling. Fitted as standard, they are slight ly too long, so can catch if driven over rough ground.

To make the curve of the cable less Light, and effectively shorten the cable, John crosses the two cables over. There is a cable guide that keeps the cables away from the prop shaft that should be checked for cracks. Ahead of the compensator is a bell crank which connects to the hand brake handle. This should be oiled, as the pivot tends to seize.