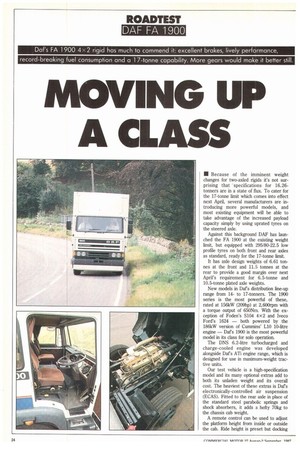

MOVING UP A CLASS

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

• Because of the imminent weight changes for two-axled rigids it's not surprising that specifications for 16.26tonners are in a state of flux. To cater for the 17-tonne limit which comes into effect next April, several manufacturers are introducing more powerful models, and most existing equipment will be able to take advantage of the increased payload capacity simply by using uprated tyres on the steered axle.

Against this background DAF has launched the FA 1900 at the existing weight limit, but equipped with 295/80-22.5 low profile tyres on both front and rear axles as standard, ready for the 17-tonne limit.

It has axle design weights of 6.61 tonnes at the front and 11.5 tonnes at the rear to provide a good margin over next April's requirement for 6.5-tonne and 10.5-tonne plated axle weights.

New models in Dafs distribution line-up range from 14to 17-tonners. The 1900 series is the most powerful of these, rated at 156kW (209hp) at 2,600rpm with a torque output of 650Nm. With the exception of Foden's S104 4x2 and Iveco Ford's 1624 — both powered by the 186kW version of Cummins' L10 10-litre engine — Dafs 1900 is the most powerful model in its class for solo operation.

The DNS 6.2-litre turbocharged and charge-cooled engine was developed alongside Dafs ATi engine range, which is designed for use in maximum-weight tractive units.

Our test vehicle is a high-specification model and its many optional extras add to both its unladen weight and its overall cost. The heaviest of these extras is Dafs electronically-controlled air suspension (ECAS). Fitted to the rear axle in place of the standard steel parabolic springs and shock absorbers, it adds a hefty 70kg to the chassis cab weight.

A remote control can be used to adjust the platform height from inside or outside the cab. Ride height is preset but docking height can be adjusted over a range of 345mm, from 1,040mm to 1,385mm. When lifting or lowering the system works impressively quickly.

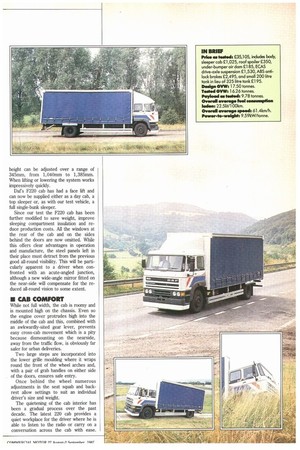

Dafs F220 cab has had a face lift and can now be supplied either as a day cab, a top sleeper or, as with our test vehicle, a full single-bunk sleeper.

Since our test the F220 cab has been further modified to save weight, improve sleeping compartment insulation and reduce production costs. All the windows at the rear of the cab and on the sides behind the doors are now omitted. While this offers clear advantages in operation and manufacture, the steel panels left in their place must detract from the previous good all-round visibility. This will be particularly apparent to a driver when confronted with an acute-angled junction, although a new wide-angle mirror fitted on the near-side will compensate for the reduced all-round vision to some extent.

• CAB COMFORT

While not full width, the cab is roomy and is mounted high on the chassis. Even so the engine cover protrudes high into the middle of the cab and this, combined with an awkwardly-sited gear lever, prevents easy cross-cab movement which is a pity because dismounting on the nearside, away from the traffic flow, is obviously far safer for urban deliveries.

Two large steps are incorporated into the lower grille moulding where it wraps round the front of the wheel arches and, with a pair of grab handles on either side of the doors, ensures safe entry.

Once behind the wheel numerous adjustments in the seat squab and backrest allow settings to suit an individual driver's size and weight.

The quietening of the cab interior has been a gradual process over the past decade. The latest 220 cab provides a quiet workplace for the driver where he is able to listen to the radio or carry on a conversation across the cab with ease.