Who'll buy safety?

Page 11

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Gibb Grace samples Antilok and is impressed

• I have never been involved in a heavy-vehicle accident, let alone a jack-knife. but last week at the Automotive Products Group's Shenington test track I was able to get as close as possible to the real thing without it actually happening. After the experience I am more than ever convinced that anti-locking brakes must eventually be adopted in one form or another—though without legislation one wonders how long it may be before the manufacturers who have spent years developing such devices will see any financial return.

At Shenington I drove two vehicles—an AEC rigid and a Ford 0800 artic—through a variety of typical hazards first without Antilok in action and then with it operating. Because Antilok is now an electrical system it was relatively easy to arrange for it to be switched in and out of operation.

Two tests On two tests, first braking on a curve in the wet and then with left-hand and right-hand wheels on surfaces of differing friction coefficient, the artic without Antilok went wildly out of control and could well have written off me and the cab had it not been for the massive restraints built in for the job. (To be fair, the trailer, carrying test weights, was not a very typical example of what the modern large artic comprises.) With this experience fresh in mind it took some nerve to repeat the exercise wholeheartedly with the Antilok switched on, But when I did so the difference was remarkable: in both instances the vehicle remained completely under control and pulled up in a very short distance. On the curve test; with Antilok, the vehicle could be steered accurately and it stayed well within the line of cones which had been demolished so vigorously before.

The two-surfaces test was equally impressive, the vehicle coming to a halt quickly, under control and in a straight line.

The only criticism was that the device's random braking and releasing of the road wheels caused the tractive unit and trailer to buck somewhat. I doubt whether the light loading of the trailer was a factor, but on the AEC rigid the bucking, as might be expected, was very much less evident.

The best results are obtained where all axles are fitted with the equipment but, as I found out from the tests, an artic with only the driving axle converted had greatly improved straight line braking, and it is very unlikely to jack-knife.

Very shortly Antilok will be available both as original equipment for new vehicles and in kit form for installation by operators on existing vehicles. Typical price of a kit for converting, say, the three axles of a six-wheeled attic will be about .£300.

The Antilok system

An anti-lock braking system makes maximum use of the road /tyre adhesion available under all road conditions. To do this it must be capable of responding to all conditions of vehicle loading, and the widely varying friction coefficients produced by different road surfaces and weather conditions.

Research has shown that to maintain near maximum braking without wheel lock under straight-line braking, the slip of the tyre with respect to the road should be kept within the range of 15 per cent to 50 per cent. However, to fully realize its potential, and to cope with braking while cornering, these figures have to be considerably improved upon.

It has been found that to achieve maximum braking and retain control under cornering, the tyre /road slip percentage must be consistently retained within the 10 to 20 per cent range under widely differing conditions. Antilok was developed to meet these requirements.

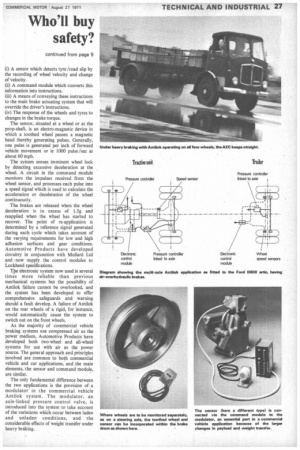

The Lockheed Antilok system has four main elements:— (i) A sensor which detects tyre /road slip by the recording of wheel velocity and change of velocity.

(ii) A command module which converts this information into instructions.

(iii) A means of conveying these instructions to the main brake actuating system that will override the driver's instructions.

(iv) The response of the wheels and tyres to changes in the brake torque.

The sensor, situated at a wheel or at the prop-shaft, is an electro-magnetic device in which a toothed wheel passes a magnetic head thereby generating pulses. Generally, one pulse is generated per inch of forward vehicle movement or ie 1000 pulse/sec at about 60 mph.

The system senses imminent wheel lock by detecting excessive deceleration at the wheel. A circuit in the command module monitors the impulses received from the wheel sensor, and processes each pulse into a speed signal which is used to calculate the acceleration or deceleration of the wheel continuously.

The brakes are released when the wheel deceleration is in excess of 1.5g and reapplied when the wheel has started to recover. The point of re-application is determined by a reference signal generated during each cycle which takes account of the varying requirements for low and high adhesion surfaces and gear conditions. Automotive Products have developed circuitry in conjunction with Mullard Ltd and . now supply the control modules to Lockheed specifications.

Tie electronic system now used is several times more reliable than previous mechanical systems but the possibility of Antilok failure cannot be overlooked, and the system has been developed to offer comprehensive safeguards and warning should a fault develop. A failure of Antilok on the rear wheels of a rigid, for instance, would automatically cause the system to switch out on the front wheels.

As the majority of commercial vehicle braking systems use compressed air as the power medium, Automotive Products have developed both two-wheel and all-wheel systems for use with air as the power source. The general approach and principles involved are common to both commercial vehicle and car applications, and the main elements, the sensor and command module, are similar.

The only fundamental difference between the two applications is the provision of a modulator in the commercial vehicle Antilok system. The modulator, an axle-linked pressure control valve, is introduced into the system to take account of the variations which occur between laden and unladen conditions, and the considerable effects of weight transfer under heavy braking.