Withdrawable Assemblies to Speed Up Repairs

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

By Mounting the Main Chassis Components on Sub-frames Removal and Replacement Times Could Be Reduced from Hours to Minutes

THERE is probably no feature in 1 cominercial-vehicle design which has been more criticized over the years than that of accessibility or, to be more precise; the lack of it. Considerable improvements have been made: in individual cases, in respect of sparking plugs, valve tappets, dynamos, and so 'on, but this is not quite the form of accessibility which the writer has in mind.

We all know that when once the body is mounted on the chassit-. anything may happen to many of the good intentions with which the chassis

designer started out. For instance, electrical faults -become a nightmare, everything being so -well boxed in that one often has to be. a contortionist to obtain a view of the wiring behind the instrument. panel.

With some types of van body the back axle is so well hidden as to render jacTsing-up an unpleasant operation, and to get the grease gun on to some chassis nipples often Means spreading one's length on the tarrnacadam.

There is a bigger issue to this question of accessibility than is represented in the inability to get at certain chassis parts in the process of carrying out running, maintenance,and this concents the complete removal of coinponents when the day for overhaul arrives or, what is, perhaps, more important, when the same operation becomes necessary in order to snake a replacement as the result of the prernatnte failure of a bearing or gear pinion.

There is much that could he done in the way of unit assembly, and one aspect of this subject. is covered in patent No, 552,185, by Mr, J, Willis, of West Didsbury, Manchester.

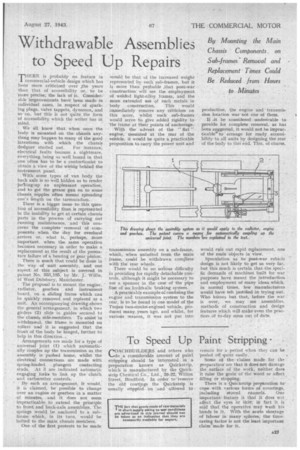

• The proposal is to mount the engine, radiator, gearbox and instrument hoard, on a sliding frame which can be quickly removed and replaced as a unit. An accompanying drawing shows the general arrangement, in which two girders (2) slide in guides secured to the chassis side-members. To assist in withdrawal, the Warne is mounted on rollers and it is suggested that the front of the body be hinged, further to help in this direction..

Arrangements are made for a type of universal joint (1) which automatically couples up thaI transmission as the assembly is pushed home, whilst the electrical connections are made with Spring-leaded plungers contacting strids. At 3 are indicated automatic engaging forks to link up the clutch and carburetter controls.

By such an arrangement, it would, it is claimed, be possible tochange over an engine or gearbox in a matter of minutes, and it does not • seem impracticable to extend the principle to front and back-axle assemblies, The springs would be authored to a subfmme• which, in its turn, would he bolted to the main chassis members. One of the first protests to be made would be that of the increased weight represented. by' such sub-frames, but it is more than probable .that post-war construction: will see the employment of welded light-allby frames, and the more extended tise of such metals in body construction. This would immediately remove any criticism on this score, whilst such sub-frames would serve to give added rigidity to the frame at their points of anchorage.

With thefl advent of the " flat " engine, mounted at the •rear of the vehicle, it would be quite a practicable proposition to carry the power unit and transmission assembly on a sub-frame, which, when unbolted from the main frame, could he withdrawn comfilete withthe rear wheels. There wduld be no sdibus difficulty in providing for rapidly detachable controls, although it might be necessary to use a spanner. in the case of the pipe line of an hydraulic braking system.

A practicable example al' confining the engine and transmission system to the rear, is to be .fotind in one mOdel of the Trojan two-stroke-engined vehicle, produced many years ago, and whilst, for various reasons, it was not put into production, the engine and transmission location was not one of them.

If -it be considered undesirable to provide for complete removal, as has been suggested, it would not be irnpracticable* to arrange for ready accessibility to all units by designing the rear of the body to this end. This, of course,

would rule out rapid replacement, one of the main objects in view. .

Speculation as to Pcist-war vehicle design is not likely to get us very far, but this much is certain that•the specific demands of machines built for war 'purposes have meant the introduction and employment of many ideas which, in normal times, few manufacturers would have felt justified in trying out. Who knows but that, before the war is over, we -may see assemblies, methods of construction and design features which will make even the practices of to-day seem out of date.