Scammell Investigating Rear engine Possibilities

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

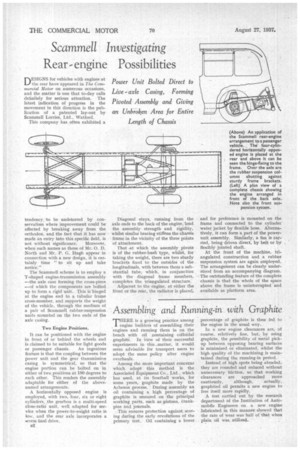

Power Unit Bolted Direct to Live axle Casing, Forming Pivoted Assembly and Giving an Unbroken Area for Entire Length of Chassis

DESIGNS for vehicles with engines at Lithe rear have appeared in The Commercial Motor on numerous occasions, and the matter is one that to-day calls definitely for serious attention. The latest indication of progress in the movement in this direction is the publication of a patented lay-out by Scammell Lorries, Ltd., Watford,

This company has often exhibited a tendency to be undeterred by conservatism where improvement could be effected by breaking away from the orthodox, and the fact that it has now made an entry into this specific field, is not without significance. Moreover, when such names as those of Mr. 0, D. North and Mr. P. G. Hugh appear in connection with a new design, it is certainly time " to sit up and take notice."

The Scamm all scheme is to employ a T-shaped engine-transmission assembly —the axle case forming the cross-piece —of which the components are bolted up to form a rigid unit. This is hinged at the engine end to a tubular frame cross-member, and supports the weight of the vehicle, through the medium of a pair of Scammell rubber-suspension units mounted on the two ends of the axle casing.

Two Engine Positions, It can be positioned with the engine in front of or behind the wheels and is claimed to be suitable for light goods

or passenger chassis. An ingenious feature is that the coupling between the power unit and the gear transmission casing is symmetrical, so that the engine portion can be bolted on in either of two positions at IS() degrees to each other. This renders the assembly adaptable for either of the abovenamed arrangements.

A horizontally opposed engine is employed, with two, four, six or eight cylinders, the gearbox is a multi-speed close-ratio unit, well adapted for service when the power-to-weight ratio is low, and the rear axle incorporates a worm final drive.

n2

Diagonal stays, running from the axle ends to the back of the engine, lend the assembly strength and, rigidity, whilst eimilar bracing stiffens the chassis frame in the vicinity of the three points of attachment.

That .at which the assembly pivots is of the rubber-bush type, whilst, for taking the weight, there are two sturdy brackets fixed to the outsides of the longitudinals, with between them a substantial tube, which, in conjunction with the diagonal frame members, completes the triangulated structure.

Adjacent to the engine, at either the front or the rear, the radiator is placed, and for preference is mounted on the frame and connected to the cylinder water jacket by flexible hose. Alternatively, it can form a part of the powerunit assembly. Similarly, a fan is carried, being driven direct, by belt or by flexibly jointed shaft.

At the front of the machine, triangulated construction and a rubber suspension system are again employed. The arrangement can be clearly understood from an accompanying diagram. The outstanding feature of the complete chassis is that the whole of the space above the frame is uninterrupted and available as platform area.