D FOR HEIGHTS

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

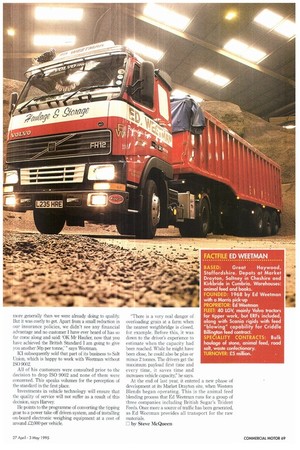

Laf it's a specialist tipper operator with an agricultural background you're after, the village of Great ywood in Staffordshire is a good place to start. Seasonal peaks and troughs are the name of the game for local tipper operator Ed Weetman (Haulage and Storage). Whether it's hauling limestone from the Derbyshire peaks for use in the sugar beet processing plants of East Anglia, blending animal feed products, or delivering them to farms around the country, Ed Weetman's vehicles are involved somewhere.

Farmer's son Weetman runs the business he founded 27 years ago: "I realised there was no living for me on the small family farm, so I went out and bought a Morris pick-up truck for £30—half of which I borrowed," says Weetman.

Perhaps unhappy with the terms of that original deal, he prefers the company to own all its assets. This includes the entire fleet of 40 LGVs and three other depots at Market Drayton, Saltney in Cheshire and Kirkbride in Cumbria. With farming in the blood, but a fascination for trucks, a haulage business with an agricultural bias was inevitable.

"I knew the farming industry, the different crops that were grown, at which times of the year and what they were used for," he says.

That experience has proved extremely handy in developing a series of contracts across the country which almost interlock.

For example, the largest slice of the business is with British Sugar's Trident Feeds. The feed is a by-product of the sugar beet processing season which runs from September to February.

"The storage and distribution operation for the animal feed works in steps. When the factories are open, we could be delivering direct from the factory to the farms, or taking the feed in one hop to the storage depots. The stored feed is distributed when the factories are closed. Feed for farms in Cumbria is sourced from Great Haywood. Once there the driver could head on to collect out of our Kirkbride store for deliveries to farms in Scotland, for example," says transport co-ordinator, Richard Harvey.

"We have tried to build alongside the M6 motorway from here to Carlisle. That way we could service the farmers, the merchants and the agricultural feed compounders to left and right of the M6," says Weetman.

The Trident Feed storage and distribution contract links very nicely with parent company British Sugar's need for limestone from the Derbyshire peak district. The stone is used in the purification process and provides a valuable source of two-way traffic for Ed Weetman.

When loads of stone are not required, a rock salt distribution contract with US-owned, but Cheshire-based Salt Union (the business was formerly owned by ICI) might be an alternative. This contract is to deliver the salt to council depots and roadside dumps in the four counties of Staffordshire, Lincolnshire, and sugar beet producing Norfolk and Suffolk. It is used for gritting roads in the winter. A result of this interlinking of cross country work, regular nights out for the drivers are a must.

Rock salt

A typical driver schedule could look like this. "He might load at Winsford, Cheshire with rock salt at 7am on Monday, or even with limestone from the Derbyshire quarries. He would then run over to Norfolk, perhaps tipping in Norwich before re-loading from either the Norwich or Kings Lynn sugar beet processing factory If he was returning here (Great Haywood), it would probably be a night out followed by a similar programme the next day," says Harvey The advantage to Ed Weetman is the luxury of originating around 90% of its own mileage.

However seasonal much of the work might be, Ed Weetman's business is not predictable.

Transport manager Tom Cheadle says the Trident Feeds contract is becoming much more of a just-in-time operation, with greater demands on the hauliers involved. Delivery lead times are becoming less, and notice of vehicle availability is getting shorter.

Both the Trident Feeds and the Salt Union contracts are serviced via direct computer links with Great Haywood, and orders can come in small or large numbers at any time of the day.

Peak demand for transport is met by employing owner drivers and/ or subcontractors, with up to 40 being commissioned at the busiest times to keep the customers satisfied.

It takes an efficient business to win and hold on to a large contract with such a high profile as British Sugar. No doubt Ed Weetman's other customers are as demanding in terms of service. So it comes as a surprise that earlier this month (April) the decision was made to drop the ISO 9002 quality standard.

"ICI insisted we achieved the standard, and we did so after doing all the preparation in-house. We already had our own driver manuals and didn't have to do much more generally than we were already doing to qualify But it was costly to get. Apart from a small reduction in our insurance policies, we didn't see any financial advantage and no customer I have ever heard of has so far come along and said: 'OK Mr Haulier, now that you have achieved the British Standard I am going to give you another 50p per tonne,' "says Weetman.

ICI subsequently sold that part of its business to Salt Union, which is happy to work with Weetman without ISO 9002.

All of his customers were consulted prior to the decision to drop ISO 9002 and none of them were concerned. This speaks volumes for the perception of the standard in the first place.

Investments in vehicle technology will ensure that the quality of service will not suffer as a result of this decision, says Harvey.

He points to the programme of converting the tipping gear to a power take off driven system, and of installing on-board electronic weighing equipment at a cost of around £2,000 per vehicle. "There is a very real danger of overloading grain at a farm when the nearest weighbridge is closed, for example. Before this, it was down to the driver's experience to estimate when the capacity had been reached. While he might have been close, he could also be plus or minus 2 tonnes. The drivers get the maximum payload first time and every time, it saves time and increases vehicle capacity" he says.

At the end of last year, it entered a new phase of development at its Market Drayton site, when Western Blends began operating. This is the animal feed blending process that Ed Weetman runs for a group of three companies including British Sugar's Trident Feeds. Once more a source of traffic has been generated, as Ed Weetman provides all transport for the raw materials.

0 by Steve McQueen