What happened at this end

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Part 2 by CM "s Alan Millar

WAITING for container OCLU 2653 and the Melbourne Express made me feel like an expectant father. I knew when it was supposed to arrive, but until the moment when it did dock, I was kept on tenterhooks. March 22 was the appointed date, then Lloyd's Register stated with authority that it would be unloaded on April 5 instead.

Imagine our horror, then, when CM editor lain Sherriff visited Tilbury docks on March 22 and found that the Melbourne Express had docked already and was being unloaded! In fact, the container went on to a clip-on refrigeration unit there and remained at the docks until March 29 when importer J. E. Sanger Ltd of Croydon was ready to put the meat into cold store.

Specialist haulier D. Cotter and Sons Ltd entered the story at that stage, dispatching a Seddon Atkinson 400 tractive unit and skeletal trailer from its

East India Docks base to Tilbury in time for an 8.15am departure with the container aboard. Ninety minutes later it was -at Frigoscandia's 5m cuft cold store at Stratford in London's East End, and unloading began. around 11.30am.

Cotter transport manager Peter Kaylor says his firm is engaged completely in meat transport. "We deliver to all parts of the country. We go anywhere that meat is eaten." His fleet is composed entirely of Atkinsons and Seddon Atkinsons which run with 20 trailers, or as four-wheel boxvans.

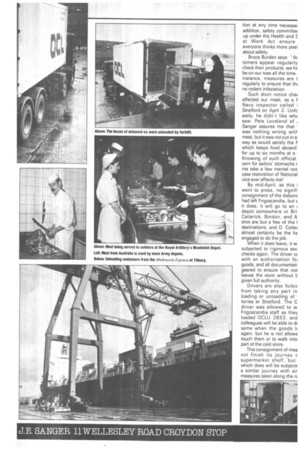

Our meat is destined for the Ministry of Defence, and Cotter's work is geared particularly towards that consistent market. It has just renewed a six-month contract with the Army, and is engaged also on a six-month naval contract. In the course of a half year, Cotter vehicles carry about 1,200 tons of Forces' meat in weekly consignments of six to 1 6 tons, with vehicles going to all of the Army's major depots throughout Britain.

When OCLU 2653 arrived at Stratford, it was put into a straight rotational system for unloading which, according to Frigoscandia general manager Bruce Burden, is essential to maintain efficient operation. The need for such a system was underlined to me when he explained that between 80 and 110 vehicles use the depot every day between 6am and lOpm, and that a large queue of vehicles awaits staff when they arrive shortly after 5am each day.

Security staff check each vehicle's seals when it arrives at Stratford. The driver books in then, and is allocated a specific unloading priority, but no time as that could go wrong all too easily, even in a well-organisad depot like Fngoscandia's.

Unloading of OCLU 2653 conformed to the usual practice, which takes about an hour and a half. The meat boxes were loaded on to pallets, taken by forklift for weighing, and moved then into the deep freezing store where they could remain for anything from two days to two years. The MoD is unlikely to want its meat to remain in store for two years, but at times when the European Economic Community is building up its beef mountain, such storage periods are commonplace and are hardly detrimental to the meat's condition.

The Stratford store was opened in 1961 and has been developed since then to become Britain's busiest cold store. It holds around 11,000 tons in its 10 chambers, nine of which work down to a temperature of —30° Centigrade. The 10th is a chilling chamber which works upwards of ODC. In addition, there are three smaller chambers in which smaller volumes of goods may be kept.

Bruce Burden says: "It is crucial to maintain temperatures at the prescribed level. We have three engine rooms to control this."

The company also ensures that the store is run on the safest possible lines. All staff are required to wear protective clothing, and smoking is prohibited on the loading bank and in the cold store itself. A doctor is based on the site, and all staff are entitled to medical examina tion at any time necessar addition, safety committes up under the Health and E at Work Act ensure everyone thinks more posi about safety.

Bruce Burden says: "As tomers appear regularly check their products, we he be on our toes all the time. instance, measures are t regularly to ensure that till no rodent infestation.

Such short notice chei affected our meat, as a f Navy inspector called Stratford on April 2. Unfc ately, he didn't like whe saw. Pete Loveland of Sanger assures me that : was nothing wrong with meat, but it was not cut in si way as would satisfy the which keeps food aboard for up to six months at a Knowing of such official cern for sailors' stomachs r me take a few mental not case restoration of National vice ever affects me!

By mid-April, as this ; went to press, no signifi consignment of the debonE had left Frigoscandia, but N, it does, it will go to an depot somewhere in Bri Catterick, Bordon, and A shot are but a few of the I destinations, and D. Cottei almost certainly be the he engaged to do the job.

When it does leave, it w subjected to rigorous sec checks again. The driver cc with an authorisation fol goods, and all documentati geared to ensure that not leaves the store without given full authority.

Drivers are also forbic from taking any part in loading or unloading of lorries at Stratford. The C driver was allowed to w Frigoscandia staff as they loaded OCLU 2653, and colleagues will be able to dr same when the goods h again, but he is not allowE touch them or to walk into part of the cold store.

This consignment of mea not finish its journey c supermarket shelf„ but which does will be subjectE a similar journey with sir measures taken along the rc