IN LAST WINTER'S freezing weather one distributor regularly got its

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

vehicles — 100 per cent with refrigeration units, carrying cheese — through to all parts of Britain.

The company with this firstclass distribution record is S. Holland and Son Ltd, of Calveley Mill, Tarporley, Cheshire. It has 25 vehicles and is a cheese factor, a buyer and seller of cheese, also undertaking distribution work to High Streets for such firms as Littlewoods and Universal Stores.

On the cheese side, Holland is probably the biggest company of its sort in the UK. So it has contributed its part to the continuation of normal life in the country during the excesses of the weather.

When I went there on the last (official) day of winter, a Cheshire manufacturer had warned us that we would be unlikely to be able to get through because of bad roads. The weather in fact did clear up, but Holland had been coping anyway. Walter Grant, general manager in charge of transport and warehousing told me: "I cannot praise the men highly enough. During the whole of this winter we had two drivers stuck one night in Wakefield; otherwise, they always got through."

So who else takes the credit? While this company believes it is the largest of its type in the UK, it is relatively small in management terms. A driver in this less bureaucratic and more intelligent outfit can feel free from criticism if he takes the long way round, using his judgment, but then learns it was not necessary. Another aspect must be maintenance; certainly no one manufacturer can step in with a claim for vehicle reliability.

Walter has been in transport all his working life: RAF transport, BRS — 22 years with Holland. He joined as a clerk round the time of the Suez Crisis, with driving jobs hard to find, when the company was mainly in fruit and vegetables, running to Liverpool market at 4 am, although cheese was growing business. He went back to driving later, became foreman and went on to sales, while retaining control of tra nsport.

"My office door is open any time," he said. "But there is no use their coming in with a ridiculous request, therefore they don't try it."

The company has 27 drivers, and their average age works out at around 35, but he has no belief in an optimum age range for the best men. "You get good old drivers and bad old drivers, good young drivers and bad young drivers," he said. "But ours are good — most of them have been here a few years and there is a reasonable 'little waiting list'.

"They are members of the United Road Transport Union and we have a good relationship with the regional office and the shop stewards. There has been no disruption.The drivers aren't salesmen but do act as our ambasadors and will help unload."

His transport manager is Hubert Sobotta, German ex-pow who joined as a driver, and he is assisted by Les Wilson. Maintenance is in the charge of Tom Barclay, who has three qualified fitters, and a third and a second-year apprentice. Drivers' daily defects sheets are acted on quickly, and there is a scheme for weekly maintenance and a full major service every 6,000 miles.

Tyres are checked and maintained by a service representative from Motor Tyres inspecting every tyre of every vehicle on Friday afternoon! Saturday morning, and the company is a member of the National Tyre Distributors Association. The mechanical refrigeration units are checked on contract by Fetter Refigeration Services.

Vehicles all do around the same mileage, 800 a week — at an average 9.04 mpg — as there is a routine by which the drivers, keeping to their own vehicles, do alternative long and short-distance routes.

The fleet is a mixture, acquired over the years; cheese was this company's bread and butter, not transport. It got four-wheel Fords, then bought Seddons, mainly because of their availablility, and started to go in for six-wheelers because the odd ton or ton-and-a-half load was being left behind by the smaller vehicles.

Now Holland is mainly rationalising on DAFs; two more six-wheel DAFs are being bought this year and fitted by Crane Fruehauf at Basildon. The fridge units are run at the chilled temperature of 37°F for mixed loads. The number of 16-tonners left in the fleet is being reduced; today's premises present fewer access problems, and average load weights are up because of increased sales.

Its distribution record is good, then, but the company is looking for more cost benefits. It is computerising its routeing now, but this, managing director Albert Murphy assured me, will not be allowed to interfere with the flexibility of operation offered to customers.

By July the management expects to have all its customers' profiles on the computer. So Holland is moving cautiously here. It means to make sure none of those hilariousbut-annoying-to-customer computer stories originates at its hq.

The company does not make changes for the sake of change. It is increasing its fuel storage capacity, but its livery has remained .virtually the same for over 20 years. A driver decides when his vehicle needs a wash, which he does himself, but on a Saturday a man comes in on rota to wash the fleet. A more recent tradition is that Walter gets together with the md, and Graham Buckle, marketing manager, sales, and Jerry Hunt, chief accountant, on most Saturday mornings to discuss business.

Besides the transport side they also have to supervise the warehouse staff, numbering 40. They can store 4,000 tons. In cheese factoring you do not, apparently, always necessarily get rid of your stocks quickest for fast turnrounds. But that's their business.

Drivers' shorter hours have not been too much of a problem; they have meant bigger loads, fewer drops. Customers have been co-operative. But Holland does not see much advantage to be gained from tachographs — "not for multiple-drop delivery, where you're stopping and starting every two minutes."

Another territory where the company is looking for an improvement is in refrigerati control. In the last few mont it has been trying the Transcc liquid nitrogen method, t new thing from BOC, whi designed it for compani doing multiple drops. "I driver operated and gives yi an immediate reduction temperature," said Walt( "whereas with a mechanic unit the temperature is slovs dragged down.

"Transcool is noiseless ai has no working parts, and h little to go wrong. It's on thr vehicles plus two more comil in. The driver presses a butt( whenever he needs a temper ture drop. for instant gas di persal, while a —Polarstrea unit is completely automati There have been no snags, b we must carefully cost it o1 and it's too early to say MP else about it now."

Albert Murphy was just cautious. "I can see advantagl and disadvantages," he sail "But we must be careful not put all our eggs in one basket.'

Holland got into groce distribution, as distinct from i historical cheese factor bus ness, after 0-licensing can in, at first moving margarin cooking oil and biscuits fl Littlewoods to the same pren ises where it was selling dlees, and so this side escalated.

Five years ago an Iris

co-operative, Mitchelstovt Creameries of County Cori bought 75 per cent of tibusiness, with an option f( the rest which it took up la August. Four thousand Iris farmers own the co-operativi and Holland sells 5,000 tons ( their cheddar a year brougl over by Pandoro, Bell Line: and B Et I, which is sold for farmers on the UK market. Irish, by the way, unlike th English, do not make chedd; during the winter. But E cheddar is matured for at lea! three months.

The company also impoh cheddar from France, German and other Continental countrie: Edam and Gouda from Hollan and Danish Blue is brought i by containers to British porl and carried to Cheshire b independent hauliers. Hollan also handles territorial cheess Caerphilly, Cheshire, Derb) shire, Double Gloucestel Lancashire, Red Leicestei Stilton and Wensleydale.

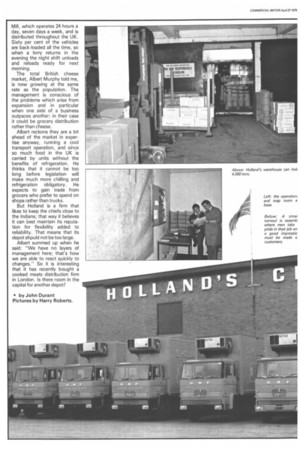

Everything comes to Ca Iverle Mill, which operates 24 hours a day, seven days a week, and is distributed throughout the UK. Sixty per cent of the vehicles are back-loaded all the time, so when a lorry returns in the evening the night shift unloads and reloads ready for next morning.

The total British cheese market, Albert Murphy told me, is now growing at the same rate as the population. The management is conscious of the problems which arise from expansion and in particular when one side of a business outpaces another: in their case it could be grocery distribution rather than cheese.

Albert reckons they are a bit ahead of the market in expertise anyway, running a cool transport operation, and since so much food in the UK is carried by units without the benefits of refrigeration. He thinks that it cannot be too long before legislation will make much more chilling and refrigeration obligatory. He expects to gain trade from grocers who prefer to spend on shops rather than trucks.

But Holland is a firm that likes to keep the chiefs close to the Indians; that way it believes it can best maintain its reputation for flexibility added to reliability. That means that its depot should not be too large.

Albert summed up when he said: "We have no layers of management here; that's how we are able to react quickly to changes." So it is interesting that it has recently bought a cooked meats distribution firm in London. Is there room in the capital for another depot?

• by John Durant Pictures by Harry Roberts.