FINE PERFORMANCE BY COMME WITH BRUSH-KOELA PRODUCER

Page 34

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

HESITANCY to depart from a long-tried practice is naturally displayed by the level-headed operator whose reputation may be at stake. This is especially so when a rather thick veil of doubt has clothed for many years the unproved path he is about to tread. Furthermore, even when circumstances arise which compel a step into the unknown, a decision may yet have to be wade as to which of several possible

steps to take. .

We have in mind the change-over from liquid to solid fuel and the problems of which fuel to use and which plant to install. The first is easy to solve. Those concerned with the development of town gas and producer gas, respectively, are almost unanimous that the scope of the former is limited to short-range operation, and the use of the latter .is best calculated to give satisfaction on journeys of at least moderate length. As to the second problem, clearly we cannot differentiate between the products of competitive makers, but, in this report, we propose to set out the claims of the Brush-Koela plant from knowledge. of it that we have gained first-hand.

Engine Modification As a basis for our test, a lorry of high repute was used, namely, a Cornmer Superpoise 3-tonner. This had been equipped for running on solid fuel by the Brush Electrical Engineering Co, Ltd., whilst the engine had been modified to the extent of raising the compression ratio to 7.4 to 1 by the fitting of a special producer-gas, cylinder head, supplied by the maker. The gas apparatus was of the new type, incorporating a number of improvements on the original design, as outlined in our issue dated April 13.

In an accompanying drawing the new features are clearly displayed. One of these is a flash boiler, comprising a triple coil of heavy-gauge steel tubing of ample bore to function for long periods with scale-depositing water, in which the injection water is now vaporized instead of relying on the hot-jacketed air intake pipe for this purpose. The coil is positioned just above the fire and it discharges steam into the air intake, controlling, by both vaporization and decomposition, the gas and furnace temperatures.

New filtering means are also now employed. Their efficiency is outstandingly high, and the gas-cleaning apparatus not only extracts solid particles from the gas, but also removes harmful chemicals, notably. acid sulphur compounds.

In the first-stage cleaner or scrubber, a new feature is the method employed of sealing the joints between filtering discs and casing. The peripheries of the former -are composed of fabric strips, which are arranged to expand by compression of the discs after the detachable inner assembly has been inserted. Pressure is applied by screwing up a nut on the centre bolt. The principle is similar to that used in certain patent bottle stoppers. Chemical treatment and a washing in (a) water and (b) oil are given by the second-stage cleaners. The former is afforded by ferric oxide (rusty iron wool) and sodium carbonate. Mention must be made of a particularly ingenious feature in connection with the washing devices. Reference to the drawing will show that gas enters, from above, a sort of diving bell, with its lower edge submerged, and it will be observed that slots of different lengths are cut in the skirt. When suction and gas speed are low, as, for example, when starting up, gas flows through the top of the longest slots with little restriction, these being above the surface of the liquid. As speed rises, a difference in pressure is created on the liquid inside and outside the "diving bell," so that the inner level sinks, exposing more slots, and the outer rises. Thus the cross-sectional area of available passage is increased, but all gas is compelled to pass through the water in the first filter, and the oil in the other. " Porcelain rings" is the name appearing on the drawing of the oil cleaner. In point of fact, there is an agglomeration of small, hollow cylinders of porcelain, rather like miniature table-napkin rings. They are normally coated with oil, and present a big area with which the gas must make intimate contact Maintenance of these filters is simple. At reasonably long intervals the liquid requires draining out by a plug underneath, whilst replacement or topping up is effected by accessible fillers, which determine the level.

Turning now to the producer itself, which is named the Duo-Draught, we would explain that, under normal running conditions, it functions on the up-draught principle. A feature, therefore, is the large fire bed, which means low air speed through the fire, relatively low temperature and little restriction. For starting up, however, a cross-draught is used, the air entering through the horizontal tuyere. This gives high velocity of flow and high temperature—desirable factors for quickly establishing gas-making conditions from cold. A valve is provided to effect the change-over from " cross " to " up," and vice versa, as and when desired, Non-stop Refuelling An incidental advantage of the up-draught system is that suction is so low that the hopper cover can be removed and a new charge introduced, while the system is functioning and the engine running, provided that there is a fair amount of fuel still left.

There has been, in the industry, some talk, in connection with the Brusli-Koela gas producer, of burntout fire bars. The true position, however, is that the maker, in common with practically all other manufacturing concerns, has experienced difficulty in obtaining material supplies and the shortage of the particular alloy required for the fire bars was, at the outset, extremely acute. Consequently, certain sets were delivered with a substitute, which the recipients were told, at the time, would not last very long, but would be replaced gratis so soon as the correct metal came to hand and proper fire bars were available. Supplies of this are now plentiful and we understand that the present fire bars are giving every satisfaction.

It is significant of the attitude of the Brush company to its clients and to the producer-gas movement in general, that the provision of these new fire bars when

necessary, and the alteration of apparatus now in the hands of operators and distributors to bring it up to date and in conformity with the new design, are being effected without charge.

A marked improvement in gas quality has resulted from the new means for introducing water. About 50 per cent, more is now con sumed, so the additional hydrogen should be in much the same proportion. Furthermore, the need for regulating the supply has been removed, because it is now automatically controlled. There is, at the intake end of the heater pipe, a non return valve, and this opens and closes several times a second, as steam is being generated, resulting in intermittent and limited feed of water and a discharge of steam in a series of puffs.

In the industrial producer, the practice is to blow in steam for a spell and then shut it off until the fire temperature has risen again, and so on. The same principle is seemingly followed with this new development. The presence of hydrogen not only enriches the gas quite considerably, raises its calorific value, but also accelerates flame speed—a by no means unimportant point at high r.p.m.

Having reviewed these new features, let us now report the behaviour of the Cornmer and plant on the road.

Prior to starting out, 55 lb. of Suncole were introduced into the empty producer, roughly filling it to the hoppei lid. The engine was then started on petrol and a paraffin torch held to the air-intake port. In 1 minute 45 seconds, the vehicle was running on gas, and the change over from cross-draught to up-draught was made 31 minutes later, by which time we had covered about a quarter of a mile. At the same time as changing over, the water feed was turned on. No regulation of the water is required, as mentioned earlier; an excess simply floods the sight feed provided.

Incidentally, for operating the wing nuts which secure the lighting-up port cover and the hopper lid, a special spanner is provided. The paraffin torch is a special device supplied with every plant, and it will be substituted, if preferred, by inflammable cartridges.

In the course of the day's run, the hopper was replenished (with the engine running) by another 15 lb. This was done largely at our request, so that we could satisfy ourselves on the feasibility of replenishing without stopping the power unit.

At the end of the day, during which there had been hillclimbing, acceleration tests, pauses for photography, etc.,

and no attempt made'to run economically, there remained in the producer 22 lb. of unconsumed fuel. Among this we can authentically state that there were no detectable signs of clinker. One or two small pieces of stone-like matter, probably among the coal, were the only foreign bodies present. Thus 48 lb. were used for the 43 miles traversed. The rates are shown in the accompanying table.

For the initial start, drawing up the fire after a pause of some duration, etc., about two-thirds of a pint of petrol were used and, during the day, one gallon of water.

A few miles to the south-west of Loughborough lies some high ground, and we headed the vehicle in this direction to observe its performance on hills. The road rises steadily most of the way, so that practically from leaving the town it was heavy going. However, we cruised at 20-25 m.p.h., occasionally dropping into third. Under such conditions, the gas vehicle is inevitably seen at its worst, because the top-gear ratio chosen for petrol is bound to he on the high side with fuel of lower heat value.

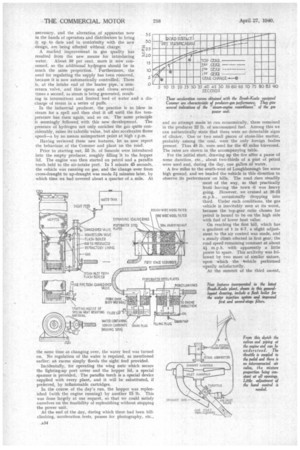

On reaching the first hill, which has a gradient of 1 in 6-7, a slight adjustment to the air control was made, and a steady climb effected in first gear, the road speed remaining constant at about 41 m.p.h. with apparently a little power to spare. This acclivity was followed by two more of similar nature, upon which the ',Thiele performed equally satisfactorily. At the summit of the third ascent, the temperature of the water in the radiator was 170 degrees F. and of the air 54 degrees F.

Then came some easier stretches of road, along which we cruised at 35-40 m. p h „ negotiating all normal undulations in a manner that would be indistinguishable from our performance o ii petrol. This section of the test represented conditions under which producer gas is certainly seen at its best.

Subsequently, we proceeded to a level stretch of new arterial road, suitable for conducting acceleration tests. The returns are graphically revealed in the accompanying set of curves. An outstanding point shown by these is that the pulling power at low speeds is excellent, better, indeed, than the accelerative power at high speeds. From a consideration of the third-gear curve, shown chain-dotted, starting from 5 m.p.h. to maximum engine rpm., it will be seen that this rises quite steeply to begin with, but flattens at the top and, indeed, our impression was that the rate of revolutions of the crankshaft was limited rather by the slow burning of the gas than by inertia loads or vibration, or the usual factors that come into play when a power unit is peaking. It will be observed, also, that acceleration in top is best between 10 and 20 m.p.h. One is, of course, speculating and groping in the dark in matters such as this, but those were our impressions.

Chassis and Body .. 2 17f Plant ., Fuel Pay-load .. 3 31 Personnel..

Total 6 9 GEAR RATIOS: 6,57, 11.74, 22.11 and 42.14 to I ; reverse, 54.2 to I.

Limiting Conditions We did not succeed in obtaining maximum speed during these tests, and the top-gear curve was still rising at 35 m.p.h. Local conditions rendered exceeding 35 m.p.h. impossible, not the ability of the vehicle to go faster_

Although Suncole was used on this trial, the company's policy is to make the producer as omniferous as possible, and experiments are being conducted with every known practicable fuel, These, in our opinion, are definitely the right lines upon which to work, Many operators and others are inquiring whether producer gas can be regarded as having a future after the war,

or whether it must be simply viewed as an emergency measure.

aniercid Motor has advocated this fuel for road transport for many years prior to the war, and our views arc in no way changed. There are to-day many engineers working independently on improving apparatus, and the outcome is bound to be substantial. As an example, already the Brush concern can ensure, judging by results of experiments, a cylinder-bore wear that approaches petrol figures. In many cases the falling-off in power is of little consequence and, even if it cannot be overcome, we do not for a moment regard it as a final check to producer-gas progress.

ENGINE: Commer; six cylinders: side valves, bore, 85 mm.; stroke, 120 mm.; piston-swept volume, 4.086 litres; rated h.p., 26.88; maximum output (petrol), 80 b.h.p. at 3,100 r.p.rn.; maximum torque (petrol), 1BG lb.-ft.; compression ratio (gas), 7.4 to I.

FUEL CONSUMPTION: 1.1 I 5 lb. per mile; 0.89 miles per lb. on day's test of 43 miles, on which 48 lb. of fuel were consumed; gross ton-miles per lb„ .5,75. Petrol consumption, 2/3 pt.; water consumption, I gallon. Range on one hopperfull, using Suncole, about 50 miles; hopper can be replenished without stop

ping engine, • FUEL EMPLOYED: Suncole,

A Strong Organization The Brush Electrical Engineering Co., Ltd., is an oldestablished company of high repute, with no fewer than 3,000 employees. It is bringing to bear upon producer-gas development many first-class brains; the Keep, Monck, Morrison, Senior combine is a strong one. It is sparing nothing' to bring its product to a highly developed state, and to organize distribution, service, and all the other matters on which its success depends to a big extent. Already nearly 100 distributors and dealers have been appointed. Such facts as these carry undoubted weight. There will be, in all likelihood, a shortage of the special fuels to which some producers, notably that evolved under Government auspices, are strictly limited. This, in our opinion, is a much more serious matter, but it is not a fundamental trouble, At the moment, according to our observations, there is a tendency to make plants as simple as possible. This can he overdone. If a degree of elaboration be required to remove some of the hindrances to producer-gas advancement, then let us have it.

The capabilities of our commercial-vehicle drivers and mechanics are adequate to cope with it, and a spot of extra maintenance is not going to frighten the type of men with whom we are familiar.