IMPROVING A WELL-KNOWN 4-TONNER.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Brief Details of the Latest Dennis, Which Embodies a New Design of Engine and Improvements in Connection with the Radiator, Bonnet, Dash, and Engine Controls.

AT FIRST sight it is difficult to detect many differences between the new Dennis 4-tonner and the 5-6-tonner which we described in our issue dated April 6th, and, in fact, in their general design they resemble each other very closely. For ,instance, the new , and highly efficient Ricardo-headed power unit of 105 mm. bore and 150 mm. stroke, which develops 70 b.h.p., is utilized in both. Clutch and gearbox are of the same type, but the torque girder has been Made lighter ; this applies also to the rear axle, and the cast-steel road wheels at the rear are hollow-spoked in the 4-tonner instead of I-spoked. The springs are, of course, not so heavy, and the frame side members have a maximum depth of 8 ins. with 2i-in. flange; they are each in one piece and without the addition of the tension members which form a feature of the heavier model. The tyres employed are 130 mm. for 850 mm. rims at the front, and at the rear 130 mm. for 881 mm. rims, these being twins. The back-axle ratio in the 4-tanner is 7.75-1 as compared with 8.75-1.

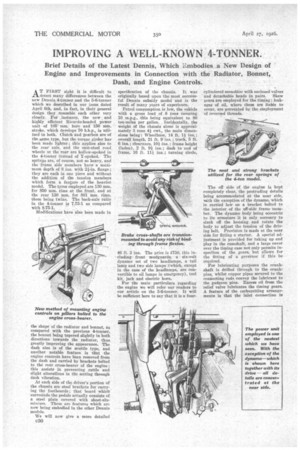

Modifications have also been made in the shape of the radiator and bonnet, as compared with the previous 4-tonner, the bonnet being tapered slightly in both directions towards the radiator, thus greatly improving the appearance. The dash also is of the scuttle type, and another notable feature is that the engine controls have been removed from the dash and carried by brackets bolted to the rear cross-bearer of the engine ; this assists in preventing rattle and slight alterations in the setting through Seth vibration.

At each side of the driver's portion of the chassis are steer brackets for carrying the footboards ; that board which surrounds the pedals actually consists of a steel plate covered with sheet-aluminium. These are features which are 31 OW being embodied in the other Dennis models.

We will now give a• more detailed specification of the chassis. It was originally based upon the most successful Dennis subsidy model and is the result of many years of experience.

Petrol consumption is low, the vehicle with a gross load of 8 tons covering 10 m.p.g.. -this being equivalent to 80 ton-miles per gallon. Incidentally, the weight of the chassis alone is approximately 3 tons 41 cwt., the main dimensions being: Wheelbase, 14 ft. 14 ins, ; overall length, 21 ft. 9 ins.; track, 5 ft. 6 ins.; clearance. 10 ills.; frame height (laden), 2 ft. 91 ins.; dash to end of frame, 16 ft. 11-1 ins.; turning circle, 46 ft. 3 ins. The price is £750, this including front• mudguards, a six-volt dynamo set of two headlamps, a tail lamp and two side lamps (which, except in the case of the headlamps, are convertible to oil lamps in emergency), tool kit, jack and electric horn.

For the main particulars regarding the engine we will refer our readers to our article on the 5-6-tanner. It will be sufficient here to say that it is a four

cylindered monobloc with enclosed valves and detachable heads in pairs. Skew gears are employed for the timing ; leakages of oil, where these are liable to occur, are prevented by the employment of reversed threads.

The off side of the engine is kept completely clear, the protruding details being accommodated at the near side, with the exception of the dynamo, which is carried low on a bracket bolted to the interior of the off-side frame member. The dynamo body being eccentric to its armature it is only iiecesary to slack off the housing and rotate the body to adjust the tension of the driving belt. Provision is made at the near side for fitting a starter. A special adjustment is provided for taking up end Play in the camshaft, and a large cover over the timing cage not only permits inspection of the gears, but allows for the fitting of a governor if this be required.

For lubricating purposes the crankshaft is drilled through to the crankpins, whilst copper pipes secured to the connecting rods convey the lubricant to the gudgeon pins. Excess oil from the relief valve lubricates the timing gears. A feature of the carburetting arrangements is that the inlet connection is water-jacketed and so divided internally that the cylinders are enabled to draw equal quantities of mixture ; a hot-spot is embodied.

The mounting of the engine and gearbox is somewhat unusual. At the front the power unit is carried in a spherical bearing, and at the rear it is bolted to a cross-bearer which also forms a support for the front end of g short channel-steel sub-frame which carries the gearbox and the bracket for the foot-brake bell-crank. The fitting of the gearbox is such that it can be dropped clear without interfering with tire body. Between it and the engine are two Hardy joints and a clutch of the external-cone type faced with Ferodo, which is ground to an _ exact angle for fitting ; its external springs can be adjusted •in a few moments. Gear changing is facilitated by the emproyment of a clutch stop.

Fonr speeds are afforded by the gearbox, which has a cover giving the maximum opening and a smaller cover which is quickly detachable for lubricating purposes. The sears are of chrome-nickel steel, whilst thc shafts are -splined and of largo diameter. The gearing is so arranged that a speed of 20 "m.p.h. can easily be achieved on the level, whilst the vehicle will climb a gradient of 1-6 with full load. Direct drive is, as usual, on the fourth speed.

Behind the gearbox is a powerful contracting shoe brake in which the metal-to-metal shoes are fulcrnmed in special carriers and balanced. by setscrews. Immediately behind this brake is a totally enclosed universal joint of the nil-metal type communicating by an open propeller joint with a smaller. joint carried in the torque-tube ball. gubbercushioned trunnions are employed for the torque-tube Wt./sing, the • brackets for this being bolted to the frame side

members. This arrangement gives a satisfactory amount of resilience and assists in preventing minor vibrations and noises from being transmitted from the axle to the chassis proper. The rubber trunnions have proved to possess an exceedingly long-wearing life, this being limited only by the natural perishing to which rubber is prone after years of use.

The torque tube itself, which acts also as a radius rod, is a substantial steel forging.

A cast-steel pot-type casing is employed for the back axle. To the sides

of the centre casting are bolted the -spring carriers, ,whilst steel tubes pass through-these into-the centre and form

bearings for the rear wheels. Final drive is by overhead worm gearing of the highly efficient Dennis type. The axle is of the full-floating type permitting the differential shafts to be withdrawn without removing the wheels or jacking up the chassis.

Following Dennis practice, the handbrake shoes in the rear-wheel drums are not enclosed. They are of the metal-tometal type and can be inspected without removal or renewed without any difficulty.

• So far as the wheel bearings are concerned, these at the roar are of the floating bush type, whilst taper roller bearings are employed for the front hubs, as will be done in future in the other Dennis models. .

• Every care has been taken throughout the chassis to prevent the passibility of binding either through lack of lubricant

or possible frame deflection. For instance, the brake crass-shafts are carried in trunnions and Tecalemit lubricators provided throughout, except for the torque-tube ball, which is lubricated from a cup carried under the off-side member of tire chassis frame. To prevent rattle at fork-and-pin joints, Thackray two-turn spring washers are employed. Further to assist the springing so that this is more proportionate to the load, neat helicoidal auxiliary springs are mounted on brackets bolted to the side members and so arranged that their ends make contact with the spring plates when the vehicle is loaded.

We were afforded an opportunity for making a short test run on this chassis, which included a number of long gradients and short hills of a severe nature, and we found the loaded vehicle easy to control and to possess a most satisfactory reserve of power,