Hybrid electric just the mixture for industry

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

deration from the various )ps. He suggested that if curnt battery technology can be ,plied to cater for these sudden irsts, then energy output of a nventional diesel engine can reduced significantly with a rresponding reduction in fuel nsumption.

The German interest in deloping hybrid systems was ry evident at this year's EVDG nference with speakers from iimler-Benz and MAN recountg their company's delopment experience. Dr Bader aimler-Benz) said that three mbinations of hybrid drive its had been tried: diesel/trolf bus, diesel/battery bus and illey/battery bus.

)r. Bader explained that a mparison of the running costs these alternative drive ;terns with those of a conven)na I diesel-powered bus 3ws that the costs for the alnative systems can be excted to be between 20 and 45 r cent higher.

\bout ten per cent of this extra 3t can, he said, be attributed to depreciation of the higher licie purchase price, and the t to the provision of infraJcture necessary for opera (depreciation and mainten3e of batteries and overhead Ner lines).

)1Bader described the hybrid 305 bus which uses a battery ctric drive system, and an iitional electric generator dri3 by a diesel engine. This ene runs at almost constant ied and achieves an operating ciency of 37 per cent, he med. However, Dr Bader adted that the diesel fuel connption is to some extent 3cted by the storage effi-icy of the battery.

Daimler-Benz has also experimented with an articulated trolley bus — called the DUO bus because of its two driving modes — which is designed to operate from overhead power lines or by means of its own installed diesel engine. Dr Bader explained that both drive units, one of which is always in operation, drive the rear axle of the vehicle via the same conventional automatic transmission.

This bus has been in regular service in Esslingen and Dr Bader claimed that the trolley arms work automatically so that there is practically no interruption when changing from one driving mode to the other.

The same type of articulated bus is also used with a battery replacing the diesel engine. Dr Bader explained that the direct current from the overhead line is first converted to an alternating current of 600 to 8 0 0Hz, transmitted by a transformer and fed into the battery after rectification. This complicated method of charging is necessary, said Dr Bader, to ensure that there is sufficiently high electrical resistance against the overhead line.

When comparing costs, Dr Bader said that even in a hypothetical case where depreciation for all three vehicles is judged to be the same as for the conventional diesel powered bus, the relative additional costs in all cases are only reduced by about ten per cent. In his experience, the lowest additional costs were incurred by the hybrid drive systems with the diesel engine, whereas the diesel/battery bus incurs about the same costs as the pure trolley bus.

Dr Bader went on to say that the undisputed advantage of electric drive is that it is the only drive system which produces no emissions. Although it is only dependent on a crude oil supply to the extent to which this oil is used to produce electrical energy, Dr Bader admitted that the price that has to be paid for these advantages is a higher consumption of primary energy and higher operating costs.

For these reasons, he suggested that its use should be limited to those areas where special environmental conditions justify it.

Representing MAN, F. Hagin and S. Martini described their company's operating experience of hydrostatic braking and flywheel systems in buses. As mechanical and hydraulic storage systems are both suitable for storing recovered braking energy, MAN has developed test versions of each system, one of these being a Gyrobus with mechanical flywheel storage and the other the Hydrobus with hydraulic storage.

Mr Martini explained that the MAN aim is to develop drive systems which yield a reduction in fuel or energy consumption of 15 to 25 per cent, as well as hay ing improved drive characterit tics, while weight and installi tion space are to remai comparable or lower.

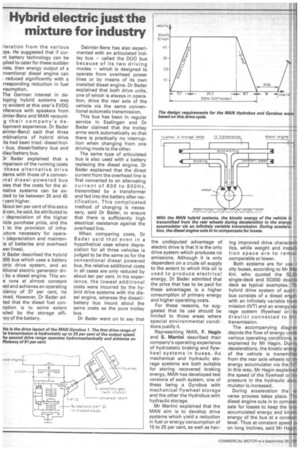

Both systems are for use i city buses, according to Mr Ma tini, who quoted the S1.20 single-deck and SD200 doublE deck as typical examples. Th hybrid drive system of such bus consists of a diesel engin with an infinitely variable tram mission (IVT) and an energy stc rage system (flywheel or hy draulic) connected to thi transmission.

The accompanying diagran depicts the flow of energy unde various operating conditions, a explained by Mr Hagin. Durin decelerations, the kinetic energ‘ of the vehicle is transmittec from the rear axle wheels to th+ energy accumulator via the IVI In this way, Mr Hagin explained the speed of the flywheel or th( pressure in the hydraulic accu mulator is increased.

During acceleration the re verse process takes place. Th( diesel engine cuts in to compen sate for losses to keep the tote accumulated energy and kinetic energy of the bus at a constan level. Thus at constant speed ol on long inclines, said Mr Hagin

diesel engine serves as the ll drive unit.

r Martini described how the el engine had a power output 100kW (135bhp) which is ut two-thirds the power of conventional city bus engine weighing 450kg (9cwt) less. Vith the Gyrobus, the MAN

Its suggest that the flywheel rgy content and the rear-axle o play a decisive role in ing fuel, and the greatest rings can be obtained with a N rear axle ratio and a iimised energy content. Mr rtini claimed that with these Icepts and a signification of drive system, a fuel saving of rre that 20 per cent can be rained with the Gyrobus (that a fuel consumption of approx3tely 31.6 lit/100km (8.9mpg)). le went on to say that even hout supplementary recharg of the flywheel to obtain iximum flywheel energy -gent, a Gyrobus with a 100kW 5bhp) engine is capable of same acceleration as a city 3 with a 150kW (200bhp) ene.

rwo versions of the Hydrobus ve been developed, explained Hagin, with Hydrobus I being lit by the Technical University Berlin and consisting of a con-itional drive system (engine d automatic drive system) ed with a hydraulic unit concted to the prop shaft for erating the hydraulic storage 3tem.

-lydrobus Ills an advanced delopment of the system for iich a new IVT system was deloped on which the hydraulic its connected to the drive stem are used both for power litting with the engine in eration and for feeding oil im and to the high-pressure )rage.

As a result of tests and exper-ice gained under actual drivg conditions, the system is beg improved, claimed Mr Hagin, th regard to greater efficiency

to approach that of a production model and also for use at higher power outputs (in articulated buses, for example).

He suggested that future areas for development should be allowing the engine to be cut out under braking as well as stopping the engine at the bus stop and restarting it hydrostatically.

Summing up, Mr Martini and Mr Hagin said that the Hydrobus and Gyrobus systems should improve the speed of public transport by between four and seven per cent. They claimed that although the greatest fuel savings can be achieved with the Hydrobus, the Gyrobus is lighter and cheaper, as well as offering more potential for future improvements.

One of the problems facing the hybrid vehicle or a pure electric-powered one is that of compatibility with other vehicles in traffic and this subject was covered jointly by J. Watson (University of Swansea) and G. A. Lee (Dragonfly Research Ltd). They claimed that a hybrid

vehicle, which instead of using electrical energy stored in heavy traction batteries uses such energy generated on board, makes possible a vehicle design which is light, fast and, above all, is user-acceptable and trafficcompatible.

Work on both a light van and a city bus was described by Mr Watson. For the former, the base vehicle chosen was a Ford Escort and Mr Watson claimed that it represented the first real attempt to fit a hybrid drive system into an everyday commercial vehicle.

One of the biggest problems facing the electric vehicle is that the ic-engined machine has over the years achieved a hig level of technical refinement and customer acceptance and around which a multi-billion pound worldwide manufacturing, servicing and refuelling infrastructive has been built.

However, Mr Watson claimed that, because of the lightness which can be achieved once power is generated on board, it is possible to retain all of the existing motor vehicle technology and simply replace the existing power unit with a hybrid unit of similar size and weight.

Describing the actual hardware, Mr Lee said that with the Escort, space and practical installation restrictions meant that the drive components had to be chosen on the basis of their ability to fit in, rather than by their technical advantage. As such he admitted that the vehicle took a step backwards in terms of design evolution.

As well as developing a hybrid van, Messrs Lee & Watson had also co-operated on the design of a system for a Seddon Pennine bus. Mr Lee explained that in spite of the fact that it was the biggest vehicle they had evE considered, it was still small i bus terms and as such there we little space available to fit in th extra machinery of a hybri system.

It was decided that to meet th average power demand durin urban operation, a prime mow and generator having a contir uous rating of 28.4kW was rf quired. Mr Lee explained ho) this could be achieved with 1.5-litre (91cuin) diesel engin compared with the original 4.! litre (275cuin) engine.

This would drive three 1016 disc generators, and six 10016 disc motors were needed t drive the rear wheels. Mr LE said that a revised configuratio was developed whereby the er gine drives the rear axle throug a hydraulic torque convert( which allows the engine to ru at a reasonably constant spee for low emissions and lor specific fuel consumption.

Mr Lee emphasised that, ec( nomically, the electric comp( nents are now reduced to mimimum with almost all troriginal vehicle equipment 13, ing kept intact. Thus, he claime■ such a hybrid vehicle does ni require any revolution in mot( vehicle technology.

He went on to say that it doE not compete against establishE ic-engined vehicle manufactu ers and does not need a brea through in battery or fuel tecl nology.

Summing up, Mr Lee said th if the motor vehicle industry ever to get back into a boo situation, either petrol prices w have to drop or vehicles w have to use less. "The first altE native is unlikely to happen. TI technology exists to achieve ti second."