SEDDON CENTRAL ENGINED BUS

Page 146

Page 147

If you've noticed an error in this article please click here to report it so we can fix it.

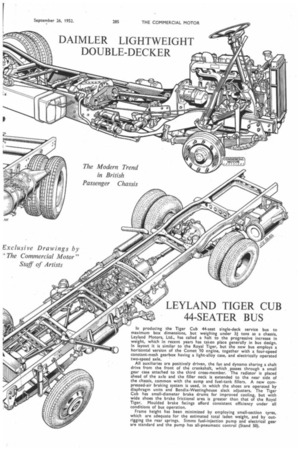

Weight saving by detail modification, coupled with the employment of welltried component parts, is the basis of the new Daimler lightweight double-decker chassis, which weighs 4* tons. In chassis dimensions and position of components, it conforms with the specification of the Society of Motor Manufacturers and Traders, having a 16-ft, 4-in. wheelbase. Conventonal tubular cross-members, with heavy welded-on cast-steel end brackets, have been replaced by lighter up-ended tubes. The frame width has been reduced and light-alloy spring brackets and spring chars are employed. The use of a Lockheed continuousflow servo braking system further reduces the weight by more than 1 cwt. and a thermo-plastic electrical conduit is employed. Light-alloy brackets are fitted to support the engine and gearbox in the frame and to carry the steering box and radiator. Because of the low weight (about 10 tons 3 cwt. fully laden) it is possible to use 9.00-20-in. tyres all round. Three power units are available—the Gardner 5LW and 6LW and the Daimler 8.6-1 tre oil engine. Noteworthy mechanical features include hydraulic actuation of the busbar of the preselective epicyclic gearbox, V-type brake cams engaging with adjustable struts, providing constant-radius shoe thrust, and R.P. s.ngle-pawl automat,c adjusters located in the strut bar (Stand 71).

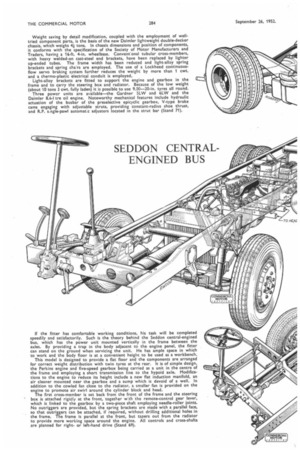

If the fitter has comfortable working conditions, his task will be completed speedily and satisfactorily. Such is the theory behind the Seddon central-engined bus, which has the power unit mounted vertically in the frame between the axles. By providing a trap in the body adjacent to the engine panel, the fitter can stand on the ground when servicing the unit. He has ample space in which to work and the body floor is at a convenient height to be used as a workbench. This model is designed to provide a flat floor and the components are arranged for correct weight distribution with twin tyres at the rear. It is of simple design, the Perkins engine and five-speed gearbox being carried as a unit in the centre of the frame and employing a short transmission line to the hypoid axle. Modifications to the engine to reduce its height include a new flat induction manifold, an air cleaner mounted near the gearbox and a sump which is devoid of a well. In addition to the cowled fan dose to the radiator, a smaller fan is provided on the engine to promote air swirl around the cylinder block and head. The first cross-member is set back from the front of the frame and the steering box is attached rigidly at the front, together w'th the remote-control gear lever, which is linked to the gearbox by a two-piece shaft employing needle-roller joints. No outriggers are provided, but the spring brackets are made with a parallel face, so that outriggers can be attached, if required, without drilling additional holes in the frame. The frame is parallel at the front, but tapers out from the radiator to provide more working space around the engine. All controls and cross-shafts are planned for rightor left-hand drive (Stand 69).

LEYLAND TIGER CUB 44-SEATER BUS

In producing the Tiger Cub 44-seat single-deck service bus to maximum box dimensions, but weighing under 3 tons as a chassis, Leyland Motors, Ltd., has called a halt to the progressive increase in weight, which In recent years has taken place generally in bus design. In layout it is similar to the Royal Tiger, but the new bus employs a horizontal uersion of the Comet 90 engine, together with a four-speed constant-mesh gearbox having a light-alloy case, and electrically operated two-speed axle. '

All auxiliaries are positively driven, the fan and dynamo sharing a shaft drive from the front of the crankshaft, which passes through a small gear case attached to the third cross-member. The radiator is placed ahead of the axle and the filler neck is extended to the near side of the chassis, common with the sump and fuel-tank fillers. A new compressed-air braking system is used, in which the shoes are operated by diaphragm units and Bendix-Westinghouse slack adjusters. The Tiger Cub has small-diameter brake drums for improved cooling, but with wide shoes the brake frictional area is greater than that of the Royal Tiger. Moulded brake facings afford consistent efficiency under all conditions of bus operation.

Frame height has been minimized by employing small-section tyres, which are adequate for the estimated total laden weight, and by outrigging the rear springs. Simms fuel-injection pump and electrical gear are standard and the pump has all-pneumatic control (Stand 50).