The Facts About

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

SLUDGING and

DILUTION

By R. W. BENT, M.I.Mech.E. IN ensuring that an adequate supply of the correct quality of lubricating oil is supplied to an engine, the manufacturer, oil supplier and user all have their part to play. . The designer's contribution is, perhaps, the most important, as he has to produce a system that will guarantee that all the moving parts receive a sufficient, but not excessive, quantity of oil.

It may be assumed that in modern engines the circulation system is reasonably satisfactory, and that the grades of lubricant available are adequate. Once the oil is in the sump, however, it suffers progressive contamination from various sources.

Despite precautions that may be taken during filling, dust and grit will still enter the oil through the breather and with the air during the induction stroke. In addition, water, caused by condensation, will mix with the oil, as will fuel from the cylinders. In a new engine, small metal chips will probably be carried along by the oil stream. • The relative effects of these different sources of contamination are not easy to determine in an actual engine, but there is no doubt that the total result is increased wear, scored bearings an`o cylinders, and generally to reduce the effective life between overhauls.

Keeping Oil Clean

Various means are used to reduce the amount of foreign matter present in the oil. Thus, the engine designer provides one or more filters, and the oil manufacturer has introduced additives to diminishthe harmful results of sludging, in particular. Lastly, the user, by regular changing af the oil, can lessen the period luring which these destructive ilements are in circulation.

Dilution, caused by the entry of fuel into the lubricant, reduces the viscosity of the oil, but this may not 116

in itself be harmful if an oil of fairly high viscosity be used. Like many other factors, the choice of a suitable viscosity tends to be a compromise. Whilst a low viscosity is desirable at low temperatures, so that the oil circulation is rapid, the viscosity should not decrease unduly at high temperatures.

Fig. 1 shows typical viscosity curves for summer and winter-grade oils, from which it will be seen that dilution will be more serious at high temperatures. On the other hand, it petrol be the diluent, evaporation will occur more rapidly with increased temperatures. As oil fuel has a higher evaporation temperature than petrol, this effect will not occur in oil engines, so that dilution will be more serious.

The obvious remedy is to reduce the causes of dilution, and this is a Matter for both the manufacturer and user. Thus, the designer of petrol engines ensures that the carburation and cylinder-head design encourage complete combustion. It is the driver's responsibility to see that the choke control is not abused In oil engines, imperfect combustion, caused by a choked nozzle, etc., is a fruitful source of crankcase dilution, so that, apart from the power loss and smoke emission, defective metering of the fuel should be attended to promptly. Worn cylinder bores and piston rings will, of course, have similar.results.

Crankcase Pressure With changes in running temperatures, the air in the crankcase will be constantly expanding and contracting. In addition, in any engine which has covered a few thousand miles, there will be a certain amount of press-um 1Qss past the rings. This is usually known as blow-by, and the result is to raise the pressure in the crankcase.

There must be, therefore, some means for allowing the excess air to escape, and the simplest js to fit a breather, sometimes incorporated with the oil filler cap. A difference of opinion appears to exist amongst designers as to the extent to which the crankcase should be ventilated, Some argue that a stream of air passing through the crankcase has a valtia.bLe cooling effect and reduces the extent to which dittition occurs, In such cases it is usual to provide both an intake and exit for the air. as shown in Fig 2..

Against this. system it is argued• that too vigorous, an air stream will tend to reduce the oil mist, which has the valuable function, in some engines, of lubricating those parts not reached by a pressure feed. Again, oxidation of. the oil Occurs, causing deposits in the oilways, and a constant flow of fresh air will increase the oxiclizina action

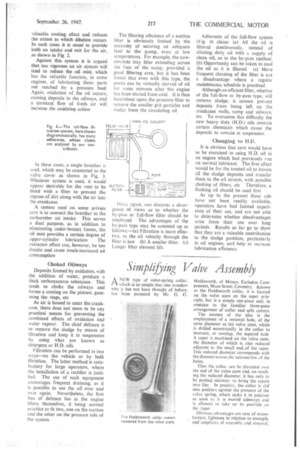

In these cases, a single breather is used, which may be connected to the valve cover as shown in Fig. 3. Whatever system is used, it would appear desirable foe the vent to be fitted with a filter to prevent the ingress of dirt along with the air into the crankcase.

A system used on some private cars is to connect the breather to the carburetter air intake. This serves a dual purpose, as in addition to eliminating under-bonnet fumes, the o4 mist peavides a certain, degree of upper-cylinder lubrication The extractor effect can, however, be too drastic and cause much-increased oil consumption

Choked Oilways

Deposits formed by oxidation, with the addition of water, produce a thick carbonaceous substance. This tends to choke the oilways and forms a coating on the pistons, gumming the rings, etc As air is bound to enter the. crankcase, there does not seem to be any practical means for preventing the combined effects of oxidation and water vapour. The chief defence is to remove the sludge by means of filtration and keep it in suspension by using what are known as detergent or H.D. oils.

Filtration can be performed in two ways—on the vehicle or by bulk filtration. The latter method is satisfactory for large operators, where the installation of a rectifier is justified. The use of such equipment encourages frequent draining, as it is possible to use the oil over and over again. Nevertheless, the first line of defence lies in the engine fibers themselves, it being normal practice to fit two, one on the suction and the other on the pressure side of the system.

The filtering efficiency of a suction filter is obviously limited by the necessity of securing an adequate feed to the pump, even at low temperatures. For example, the nowobsolete tray filter extending across the face of the sump, provided. 'a good filtering area, but it has been found that even with this type, the pump can be virtually starved of oil for some minutes after the engine has been started from cold. It is thus incumbent upon the pressure filter to remove the smaller grit particles and sledge from the circulating oil He; e, again, one discerns a divergence of views as to whether the by-pass or full-flow filter should. be employed The advantages of the by-pass type may be. summed up as follows:—(a) Filtration is more effective, as the oil velocity through the filter is low (b) A smaller filter. (c) Longer filter element life. Adherents of the full-flow system (Fig. 4) claim: (a) All the oil is filtered Continuously, instead of diluting dirty oil with a supply of clean oil, as in the by-pass method. (h) Opportunity can be taken to cool the oil as it is filtered . (c) More frequent cleaning of the filter is not a disadvantage where a regular maintenance schedule is practised

Although an efficient filter, whether of the full-flow or by-pass type, will remove sludge, it cannot prevent deposits from being left on the crankcase walls,. sump and oilways, etc. To overcome this difficulty the new heavy duty (H.D.) oils contain certain chemicals which cause the deposits to remain in suspension.

Changing to H.D.

it is obvious that care would have to be exercised in using HD. oil in an engine which had previously run on normal lubricant. The first effect would be for the treated oil to loosen all the sludge deposits and transfer them to the oil stream, with possible choking of filters, etc Therefore, a flushing oil should be used first

As up to the present these oils have not been readily available, operators have had limited experience of their use, and are not able to determine whether disadvantages arise from their use over long periods. Results so far go to show that they are a valuable contribution to the sludge problem, particularly in. oil engines. and help to increase lubrication efficiency