A SCIENTIFICALLY CONSTRUCTED DISC WHEEL.

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

M ANY have been the trials and tribulations of those designers and manufacturers who took upon their shoulders the production of disc wheels for heavy vehicles. Of the many types produced few can be said to be really satisfactory. Wheels which, to all appearances, would seem to be satisfactory, fail rapidly in service. The effect of vibration and the reversal of stress causes rivets and bolts to become loose, the holes in the discs to give way owing to cracks, whilst in certain instances the resulting slackness causes the discs to • cut into the wheel hubs, with disastrous results until finally it has been proved that reliance cannot be placed upon bolts and rivets when used in this connection as load-bearing members.

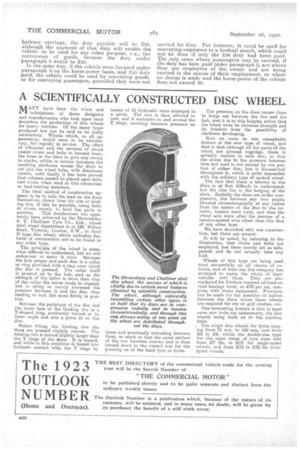

The ideal method of construction appears to be to take the load on the discs themselves' direct from the rim or binding tire, if this be possible, using bolts or rivets merely to hold the parts in position. This desideratum has apparently been achieved by the Shrewsbury S. T. Ohalliner Tyre Co., Ltd., whose steel wheel department is at 120, Wilton Road, Victoria, feeridon, S.W., in their D type disc wheel, which embodies features of construction not to be found in any other type.

The principle of the wheel is somewhat difficult to understand, but we will endeavour to make it clear. Between the hub proper and each disc is a collar or ring provided with a step over which the disc is pressed. The collar itself is pressed on to the hub, and as the strength of the latter is more than that of the collar the latter tends to expand, but in doing so merely increases the pressure between it and the disc, thus tending to lock this more firmly in position_ Between the periphery of the disc and the inner face of the binding tire is a T-sheped ring, accurately turned at its inner angle and also a press fit on the disc.

Before fitting the binding tire the discs are pressed slightly convex. The binding tire is turned slightly larger than the T rings of the discs. It is heated, and while in this condition is forced into intimate contactwith the T rings by

means of 16 hydraulic rams arranged in a circle. The tire is then allowed to cool, and it contracts on and around the T rings, exerting immense pressure on these and practically extruding between them, so much so that the outer surface of the tire becomes convex and is then turned down to the correct size for the pressing on of the band tyre or tyres. The pressure on the discs causes these to bulge out between the tire and the hub, and it is to this bulging action that the wheel owes its immense strength and its freedom from the possibility of slackness developing.

Now we come to one remarkable feature of the new type of wheel, and that is that although all the parts of the Wheel are pressed together, there is actually tension in each disc, so that the stress due to the pressure between tyre and road is not carried by one portion of either disc, but is tranemitted throughout it, which is quite impossible with the ordinary type of spoked wheel.

The fact that there is tension in the discs is at firat difficult to understand, but the clue lies in the bulging of the discs. Radially the discs are under compression, but between any two points situated circumferentially at any radius from the centre of the disc to the exterior, tension must exist, and thus the wheel acts more after the manner of a tension-spoked wire wheel than like that of any other type.

We have described only one construction, but there are several.

It will be noted, by referring to the illustration, that rivets and bolts are employed, but these merely act as safeguards and do not actually take any load.

Wheels of this type are being used most successfully on all classes of vehicles, and at least one bus company has arranged to equip the whole of their vehicles with them. They are also marketed for Fordson tractors utilized on road haulage work; at £70 per set, complete with brake equipment. Provision can be made for the insertion of ballast between the discs where these wheels are required. for use on golf courses, etc.

One interesting feature is that in most eases new hubs are unnecessary, the disc wheels being built on to the existing hubs.

-The single disc wheels for tyres ranging from 75 mm. to 160 ram, cost from £5 to £9, whilst the double-size type for the same range of tyre sizes cost from £7 10s. to £12 for single-tyred wheels, and from £12 to £25 for twintyred wheels.