How to Keep Your Lorry Fit.—X.

Page 5

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

Clayton Wagons are Each Subjected to Severe Tests Before Leaving the Works. Their Future Success is, to Some Extent, in the Hands of their Drivers.

The driver of a steam wagon is looking after his employer's interests who, while getting through his work expeditiously, nevertheless does this without racing the machine. He will also take care, so far as lies in his power, that his machine is not overloaded. After that, his duties lie in the direction. of care of his chassis. and in the lubrication of its working parts.

Lubrication.

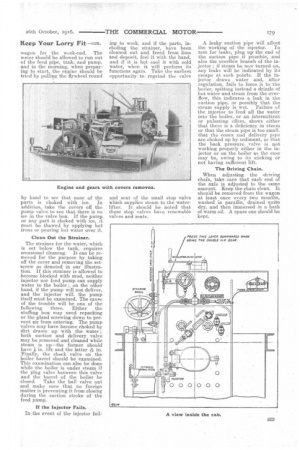

. Two grades of oil are recommended for use on the Clayton steamer. The engine main bearings and rear axle boxes should be filled with a good quality engine oil. The cylinder mechanical lubricator and the auxiliary lubricators on the high pressure and low pressure cylinders should be filled with a good quality non-carbonizing cylinder oil. A mixture of equal quantities of these two serves for the remainder of the bearings, such as the connecting-rod bear_ ins, crosshead guides, valve-red guides, front-axle journals, master pin, and front turntable, all of which should be well and frequently lubricated. The engine gearwheels and the driving chain may be greased with cylinder oil, or, in the alternative, a good quality lubricating grease. In the event of oil being used for the purpose, the inside of the chain should be brushed daily with oil, and a coating of vaseline applied to prevent the oil being thrown off. Vaseline alone is useless, as the working parts become dry and the chain wears rapidly.

Engine Control.

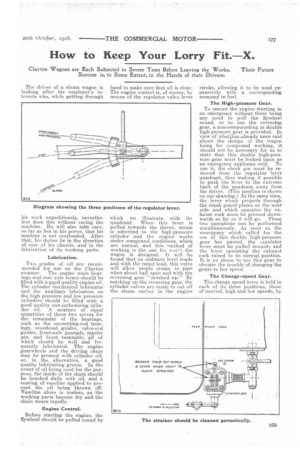

Before starting the engine, the flywheel should be pulled round by hand to make sure that all is clear. The engine control is, of course, by means of the regulator valve lever

which we illustrate with its quadrant. When this lever is pulled .towards the driver, steam is admitted to the high-pressure cylinder and the engine works under compound conditions, which are normal, and this method of working is the one fel wide:, the wagon is designed. It will be found that on ordinary level roads and with the rated load, this valve will allow ample steam to pass when about half open and with the reversing gear "notched up." By notching up the reversing gear, the cylinder valves are made to cut off the steam earlier in the engine stroke, allowing it to be used expansively with a corresponding economy in fuel.

The High-pressure Gear.

To ensure the engine starting in an emergency without there being any need to pull the flywheel round, or to use the reversing gear, a non-compounding or double high-pressure gear is provided. In view of what4has-already• been said about the design of the wagon being for compound working, it should not be necessary for us to state that this double high-pressure gear must be looked upon as an emergency appliance only. To use it, the check pin must be removed from the regulator lever quadrant, thus. making it possible to push the lever to the extreme limit of the quadrant away from the driver. (This position is shown on our drawing.) At the same time, the lever which projects through the crank guard plates on the near side and which operates the exhaust cock must be pressed downwards as far as it will go. These two operations can be performed simultaneously. As soon as the emergency which called for the use of this double high-pressure gear has passed; the iegulator lever must be pulled inwaids and the lever operating the exhaust cock raised to its normal position. It is an abuse to use this gear to obviate the trouble of Changing the gears to low speed, .

• The Change-speed Gear.

The change speed lever is held in each of its three positions, those of neutral, high and low; speeds, by nueans of a pin which engages with lever and quadrant. It is important to see that this pin is in its proper place before starting the engine. No attempt should ever be made to change the gears when on an incline.

Locking the Differential.

In wintry weather, when about to pass over parts of roadway which the driver's experience will tell him are likely to occasion slipping of the driving wheels, the compensating gear on the rear axle should be locked. This is effected by inserting a pin in the rear-wheel centre nearest the driving chain. This pin should be removed as soon as the difficult portion of the road is passed, as with the differential gear locked, the wagon cannot readily be steered round a corner.

Brakes.

There are two brakes 'provided on Clayton wagons. One takes effect on the engine flywheel, and is operated by pedal ; the other, operated by a hand wheel in the cab, tightens a band brake attached to the rear axle of the wagon. It is the latter brake which should he used. When beginning a long descent, it is as well to get the wagon in hand immediately and not to allow it to exceed a reasonable speed. When this does happen, the engine frequently attains speeds per revolution in excess of those which would normally occur, with the result that such mishaps as the seizing of eccentric straps and similar bearings may occur. This can be obviated by never allowing the wagon to get out of control going down hill. It is important that care be exercised when opening the regulator valve on a down grade. If the engine is running above the normal speed, and this valve is opened fully and suddenly, damage to the engine will probably result.

The Water Supply: The water supply to the boiler while the wagon is travelling is by means of the feed pump ; when standing, the injector should be used. When approaching a steep hill the water level should be allowed to fall so that about 1 in, of water appears in the glass. Before going down hill, the gauge should show 3 ins, of water.

The method of firing a steamwagon boiler is important. The capacity of a driver may invariably be rated by his skill in performing this operation. The fire bars should always be covered with fuel and the fire uniform in thickness, without being more than 2 or 3 ins. thick. If hard coals are used, very little trouble will be experienced from the accumulation of clinker ; with soft coal it is necessary to remove this clinker at ieast once a day. When coke is the fuel, clinker will need removing every 15 or 20 miles. The simplest way to perform this operation is to clear one side of the bars at a time, removing the fire in each case to the

opposite side. •

Beep 'a Clear Fire.

A clear fire should be kept so as to prevent smoke as much as possible. Before passing through towns or villages, the fire should be made up so that it will have burnt eufficiently to keep up steam without making any smoke. Steam pressure and the height of the water should be kept uniform. The pressure may be regulated to a considerable extent by means of the damper.

Examine While Taking in Water.

The steam-wagon driver, unlike the petrol man, has frequent

opportunity for occasional examination and for paying little attentions to the mechanism of his lorry. We have recently drawn attention to the period of firing up as being a convenient one in this respect. Water, as is well known, has to be taken for a steamer about every 15 or 20 miles. On each of these occasions the driver has further opportunity of walking round his engine and examining the working parts and applying a little lubtreating oil where needed.

Laying Up for the Night.

When nearing the end of the day's journey, the fire should be allowed gradually to die, the steam pressure falling also until there is only 10 to 20 lb. pressure left in the boiler ; this will be sufficient to house the wagon when the destination is reached. During this time however, the feed pump should be left on so that when the wagon is housed the water level will be a few inches above the working level. About 2 ins, of this should be blown off by opening the blowoff cock on the gearing side of the fire-box bottom near the ground. By this operation, a great amount of dirt is blown out from the boiler. The boiler is then left filled ready for the next day's work. Before leaving, the engine should be wiped over with cotton waste, the bright parts greased, and the waterproof engine curtain carefully drawn to protect it from the weather ; finally, draw the damper.

Precautions in Winter.

At the present time, with the winter coming on, the experienced driver will know that he must each evening leave his wagon so that the danger of damage by freezing up of water in the pipes or other parts may be obviated. This caution is particularly important when leaving, the wagon for the week-end. The water should be allowed to run out of the feed pipe, tank, and pump, and in the morning, when preparing to start,. the engine should be tried by pulling the flywheel round by hand to see that none of the parts is choked with ice. In addition, take the covers off the pump valve to see that there is no ice in the valve box. If the pump or any part is choked with lee, it must be thawed by applying hot irons or pouring hot water over it.

Clean Out the Strainer.

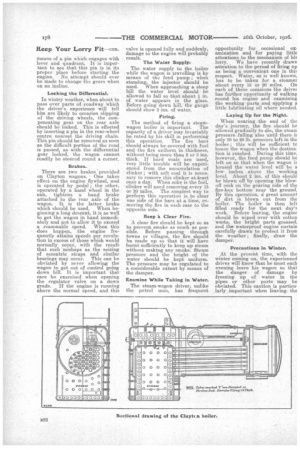

The strainer for the water, which is set below the tank, requires oneasional cleaning. It can be removed for the purpose by taking off the cover and removing the setScrew as denoted in our illustration. if this strainer is allowed to become blocked with mud, neither injector nor feed pump can supply water to the boiler ; on the other hand, if the pump will not deliver, and the injector will, the pump itself must be examined. The cause of the trouble will be one of the following three. Either the stuffing box may need repacking or the gland screwing down to prevent air from entering. The pump valves may have become choked by dirt drawn up with the water ; both suction and delivery valve may be removed and cleaned while steam is up—the former should have in. lift and the latter in. Finally, the check valve on the boiler barrel should be examined. This examination can also be done while the boiler is under steam if the plug valve between this valve and the barrel of the boiler be closed. Take the ball valve out and make sure that no foreign matter is preventing it from closing during the suction stroke of the feed pump.

I! the Injector Fails.

In the event of the injector fail

ing to work, and if the parts, including the strainer, have been cleaned out and freed from lime and deposit, feel it with the hand, and if it is hot cool it with cold water, whenit will perform its functions again. Take the earliest opportunity to regrind the valve and scat of the small stop valve which supplies steam to the waterlifter. It should be noted that these stop valves have renewable valves and seats. A leaky suction pipe will affect

the working of the injector. To test for leaks, plug up, the end of the suction pipe it possible, and also the overflow branch of the injector; if steam be now turned on, any leaks will be indicated by its escape at such points. If the injector draws water and, after regulation, fails to force it to the boiler, spitting instead a drizzle of hot water and steam from the overflow, this indicates a leak in the suction pipe, or possibly that the steam supply is wet. Failure of the injector to feed all the water into the boiler, or an intermittent or pulsating effect., shows either that there is a deficiency in steam. or that the steam pipe is too small, that the cones and delivery pipe are choked up by sediment, or that the back pressure. valve is. not working properly either in the injector or on the boiler as the case may be, owing to its sticking or not having sufficient lift.

The Driving Chain.

When adjusting the driving chain, take care that each end of the axle is adjusted to the same amount. Keep the chain clean. It should be removed from the wagon at least. once every two months, washed in paraffin, drained quits dry, and then immersed in a bath of warm. oil. A spare one should be kept.