a new spin on

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

F LTERS

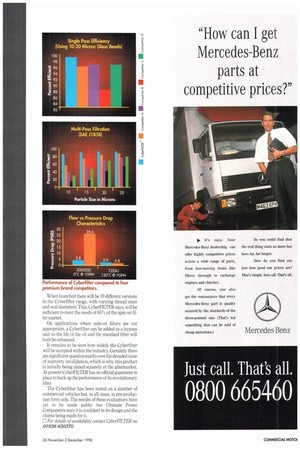

Chris Graham looks at the introduction of a state-of-the-art engine oil filter which features a woven-glass "micro-fibre" in place of paper. It is set to save fleet operators downtime and disposal costs.

It's rare these days that anything genuinely new and different appears in the vehicle component market. Most product launches are revamped or updated versions of previous ideas but, with the new Cyberfilter, CM is pleased to report on an innovative and apparently revolutionary design.

The product in question, the brainchild of British inventor Leslie Selsdon, is the first all-plastic oil filter we have come across: its potential for all aspects of this industry could be enormous.

Full-scale production is now under way in the US and the Cyberfilter will be marketed in the UK from the end of this month. It is said to provide a better and more uniform level of filtration than convtintionai spin-on filter units.

Ashley Letts, sales and marketing manager at UK distributor CyberFILTER, explains: "Current conventional filters have a paperbased filtering element which is either pleated or wound, depending on the design. The effectiveness of this varies significantly from version to version, because of variations in filtering screen size.

"The problem is that paper compression can never be a wholly exact science." he adds. "On average a typical oil filter will extract particles down to about 30 microns in diameter. It is possible to filter out smaller particles but this requires special technology and the expense involved rockets."

The Cyberfilter is able to remove particles measuring as little as 10 microns in diameter thanks to a specially developed woven glass micro-fibre in place of the traditional compressed paper. The micro-fibre is formed into a pleated element and is available in tape widths of two, three or four inches.

"The beauty of this approach is its complete predictability." says Letts "The tape can be woven to any screen size desired with assurance. We chose 10 microns as the limit, which represents a sizeable leap forward in filtering effectiveness when compared with all other conventional units."

Traditionally, the penalty paid for finer filtration is a reduction in flow rate. To overcome this the surface area of the filtering medium has to be increased to compensate. But there are practical limits to this—nobody wants a filter the size of a dustbin!

Letts claims the total surface area of the Cyberfilter element is significantly greater than that of a conventional paper-based unit, and because of this the flow rates remain high even though filtration down to 10 microns is taking place.

He says: "The undesirable knock-on effect of reducing the flow rate is that pressure drop across the filter increases. On average this is 5-7psi on a typical paper-based version. With a similarly sized and specified Cyberfilter this is reduced to just 1.5psi."

The designers claim that much more contaminant can be taken in by the Cyberfilter before the critical point is reached and pressure starts to drop across the filter. This means the oil is kept cleaner for longer. From a performance point of view, the arguments in favour of the Cyberfilter appear persuasive. But this is only half the story. The environmental potential is significant, too.

Letts points out that the Cyberfilter's all-plastic construction makes it completely recyclable. Apart from this the rigid plastic casing has other useful properties as well. "It prevents the oil from cooling as quickly as it might in a metal casing, plus it allows it to heat up faster too," Letts explains.

The Cyberfilter has been produced to be totally interchangeable with all other screwon filters. It is not built as approved original equipment but is produced to exact OE specification. All pressure relief and drain valves are included as required.

CyberFILTER is careful not to make definite recommendations about the extension of the drain intervals which are possible when using the Cyberfilter; it prefers to leave the matter to the discretion of the operator. The suggestion is that one oil change in three can be removed, but information relating to specific mileages is not available.

The consequent reduction in downtime is one of the biggest selling points associated with the Cyberfilter. But who will buy it? Letts points out: "We have not touched the OEMs at all yet. Our aim so far has been to target the aftermarket. With time we are sure the OEMs will establish contact with us." When launched there will be 19 different versions in the Cyberfilter range, with varying thread sizes and seal diameters. This, CyberF1LTER says, will be sufficient to meet the needs of 85% of the spin-on fil. ter market.

On applications where spin-on filters are not appropriate, a Cyberfilter can be added as a bypass unit so the life of the oil and the standard filter will both be enhanced.

It remains to be seen how widely the Cyberfilter will be accepted within the industry. Certainly there are significant question marks over the dreaded issue of warranty invalidation, which is why this product is initially being aimed squarely at the aftermarket. At present CyberFILTER has no official guarantee in place to back up the performance of its revolutionary filter.

The Cyberfilter has been tested on a number of commercial vehicles but, in all cases, in pre-production form only. The results of these evaluations have yet to be made public but Ultimate Power Components says it is confident in its design and the claims being made for it.

El For details of availability contact CyherFILTER on 01938 850370