Watch remanufactured parts

Page 119

If you've noticed an error in this article please click here to report it so we can fix it.

Following the Workshop conference and exhibition there have been various developments on some of the subjects that were discussed. We keep you up to date with the latest events in the worlds of brake remanufacturing and tyre regrooving

• The activities of the so-called spurious brake remanufacturers were discussed at the Workshop conference. Recent examination of an actuator fitted to a Leyland Roadrunner, after it had failed its annual vehicle inspection because of low air pressure, revealed that it had been remanufactured using dangerous parts.

When the tandem actuator was removed and taken up to full working pressure, it exploded. Leyland DAF has warned that "Clayton Dewandre tandembrake actuators (Clayton part number APSA 10457/Leyland part number ACU 7334) as fitted to Roadrunner and 300 engined variants of the Lightweight Freighter, are being reconditioned using non-genuine parts, and sold through some autofactors."

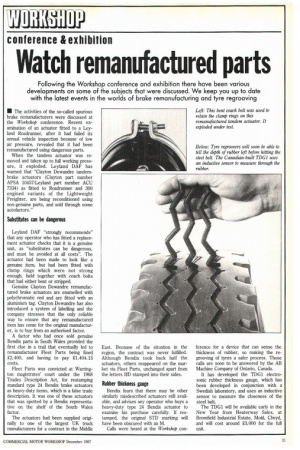

Substitutes can be dangerous Leyland DAF "strongly recommends" that any operator who has fitted a replacement actuator checks that it is a genuine unit, as "substitutes can be dangerous, and must be avoided at all costs". The actuator had been made to look like a genuine item, but had been fitted with clamp rings which were not strong enough, held together with coach bolts that had either bent or stripped.

Genuine Clayton Dewandre remanufactured brake actuators are enamelled with polychromatic red and are fitted with an aluminium tag. Clayton Dewandre has also introduced a system of labelling and the company stresses that the only reliable way to ensure that any remanufactured item has come for the original manufacturer, is to buy from an authorised factor.

A factor who had once sold genuine Bendix parts in South Wales provided the first clue in a trail that eventually led to remanufacturer Fleet Parts being fined £2,400, and having to pay £1,404.15 costs.

Fleet Parts was convicted at Warrington magistrates' court under the 1968 Trades Description Act, for restamping standard type 24 Bendix brake actuators as heavy-duty items, which is a false trade description. It was one of these actuators that was spotted by a Bendix representative on the shelf of the South Wales factor.

The actuators had been supplied originally to one of the largest UK truck manufacturers for a contract in the Middle East. Because of the situation in the region, the contract was never fulfilled. Although Bendix took back half the actuators, others reappeared on the market via Fleet Parts, unchanged apart from the letters HD stamped into their sides.

Rubber thickness gauge

Bendix fears that there may be other similarly misdescribed actuators still available, and advises any operator who buys a heavy-duty type 24 Bendix actuator to examine his purchase carefully. If restamped, the original STD marking will have been obscured with an M.

Calls were heard at the Workshop con

ference for a device that can sense the thickness of rubber, so making the regrooving of tyres a safer process. Those calls are soon to be answered by the AB Machine Company of Ontario, Canada.

It has developed the TDG1 electrosonic rubber thickness gauge, which has been developed in conjunction with a Swedish laboratory, and uses an inductive sensor to measure the closeness of the steel belt.

The TDG1 will be available early in the New Year from Heaterway Sales, at Bromfield Industrial Estate, Mold, Clwyd, and will cost around 23,000 for the full unit.