A SENTINEL OF THE [ILLS

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

y John F. Moon, New Sentinel Medium Six-wheeler Performs Well Up and Down the Horseshoe Pass-: Increased Engine Power, Air Brakes and Trailing Axle Provided WITH the mountains of Wales virtually in their backgardens, the engineers of Sentinel (Shrewsbury), Ltd., have all the inducements to produce vehicles that will perform well on hills. Their latest chassis upholds this tradition and shows a complete disregard for any gradient, however severe, as was evidenced during a recent test.

The ascent of the notorious Horseshoe Pass, apart from requiring the use of indirect ratios, did not trouble the chassis in the slightest and, similarly, the 9-mm. descent, using the brakes alone, reduced their efficiency by a mere 2 per cent. Coupled with an economic consumption rate and a useful payload capacity, the new Sentinel medium six-wheeler should prove popular with hauliers requiring a powerful but economical load carrier.

Six-cylindered Engine

It could be likened to a combination of several of the maker's existing models, having a six-cylindered oil engine and a rear bogie with trailing axle. Thus it has a greater power margin and load capacity than the popular light six-wheeler, but a lighter form of construction and greater transmission efficiency than the heavy six-wheeler. It bears the usual Sentinel hallmark of an underfloor horizontal engine, with the roomy accommodation for the crew and driving comfort which such an engine position permits.

The 9.12-litre engine, which previously developed 120 bhp. at 1,800 r.p.m., now has an output of 123 b.h.p. at 1,900 r.p.m. and the torque has also been increased by 6-1b.-ft. to 381 lb.-ft. at 1,150 r.p.m. These changes have been effected with no modifications to the engine other than the alteration of the governor setting to allow higher speed.

Accessible Power Unit It is a direct-injection unit with -a bore and stroke of 4* in. and 51 in., respectively, and has twin cylinder heads which extend from below the right-hand chassis side-member, where they are readily accessible for routine maintenance purposes.

A C.A.V. fuel-injection pump, which has a mechanical governor, is carried transversely across the front of the engine, being protected by a detachable canvas gaiter. Air brakes are standard on this chassis and the Clayton Dewandre compressor is situated at the front of the engine and is driven by a twin V-belt. A shaft is taken forward from this drive for the fan and dynamo which are located beneath the cab floor behind the forward-mounted radiator.

A David Brown 557, five-speed direct-top gearbox is bolted to . the engine in a vertical position and it has a central turret for the selector mechanism. This, in addition to reducing the linkage to the changespeed lever, simplifies conversion for leftor right-hand drive.

The engine and gearbox unit is supported flexibly on Metalastik components which allow it to oscillate on an axis between its centre of gravity and the front propeller-shaft joint. The lack of engine vibration transferred to the chassis was noticeable throughout the test.

A single propeller shaft with Hardy Spicer needle-roller joints connects the gearbox to the centre, driven axle. This has an overheadworm final-drive gearing with 8±-in, centres and two ratios are available —6.25 to 1 or 5.2 to 1, the former ratio being fitted to the chassis provided for the test. The trailing axle has a stout tubular beam, and four equal-length springs are used for the bogie suspension.

So that a high proportion of the chassis weight may be imposed upon the driving axle, the rocking beams which link the springs at each side of the chassis are pivoted in the ratio of 5 to 7. This is claimed to provide traction over bad surfaces equivalent to that normally experienced with a double-driye bogie.

• Improved Steering

The wheels of the rear bogie are fitted with 9.00-20 in. (12-ply) tyres, whilst 10.00-20 in. (14-ply) tyres are fitted to the front axle. Marks cam and double-roller steering gear is used, and in spite of the large tyres and 5-ton axle loading, the steering was not found to be unduly heavy. I was given to understand that the castor angle has been reduced on current Sentinel models with a corresponding reduction in steering effort.

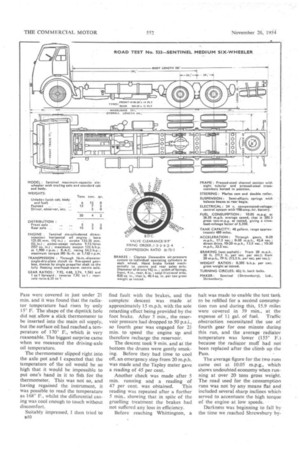

Complete with cab, a standard 23-ft. 6-in, platform body and a full tank of fuel, the Sentinel weighed. 6 tons 12 cwt. The payload consisted of large concrete blocks and totalled 13 tons 71 cwt. The gross vehicle weight of nearly 201 tons was, therefore, slightly over the maximum which the. proposed new Construction and Use Regulations would allow for a three-axled goods vehicle, but as the test showed, this payload was well within the capacity of the chassis.

I was accompanied throughout the test by two Sentinel representatives, and from the works we wended our way through the tortuous streets of the old town of Shrewsbury. The Sentinel appeared to handle well and, in spite of its length, the good steering lock provided for the negotiation of sharp corners with confidence.

It was pleasant to sit in a forwardcontrol cab without having to endure the pulsating din of an engine, and although the weather was cold, the interior of the cab remained pleasantly warm.

For those reqUiring further cab heating, there is a shutter in the fan cowling which, when opened, allows warm air to be forced into the cab from behind the radiator.

The ambient temperature of 46° F. necessitated the complete blankingoff of the radiator grille, and by the time Montford Bridge was reached the radiator top-tank temperature

was recorded as 166° F. The combination of the large radiator and greatly exposed engine caused normal running temperatures to be lower than with a conventional vehicle. For general operation in this country, the radiator size could beneficially be reduced, At Montford, the 2-gal, test tank was topped-up and a consumption run was conducted along the A5 in the general direction of Llangollen. The run was, for the most part, made

in top gear, but traffic in Whinington necessitated a 15-sec. stop and 15.8 miles were covered at an average speed of 28:2 m.p.h. The test tank required 131 pints for refilling, which is equivalent to a Consumption rate of 91 m.p.g.

While switching the taps over to the main-tank supply, it was noticed that the tap from the test tank was seeping slightly and as this would have had an adverse effect upon the consumption rate, for the return run, to be conducted later in the day, it was decided to by-pass the tap and reduce the risk of further leakage.

On reaching Llangollen, we left the AS and headtd towards the Horseshoe Pass. The radiator blanking was dropped to uncover a quarter of the grille, and at the bottom of the climb, with an ambient temperature of 50° F., the radiator temperature was 165° F. Soon after starting, top gear was engaged, but second gear became necessary at the Britannia Inn, where there are sharp leftand right-hand bends with 1-in-5 gradients.

I expected that low gear would be necessary here, but the staying power of the engine was such as to take the vehicle round the second bend without having to change down. Higher up the Pass, a short section on which the Tapley registered 1 in 5 proved just too much for second gear and use was made of the lowest ratio, the change being effected when the chassis had almost come to a halt.

The 3.6 miles to the top of the

Pass were covered in just under 21 min. and it was found that the radiator temperature had risen by only 5' F. The shape of the dipstick hole did not allow a stick thermometer to be inserted into the main oil supply, but the surface oil had reached a ternperature of 170' F., which is very reasonable. The biggest surprise came when we measured the driving-axle oil temperature.

The thermometer slipped right into the axle pot and I expected that the temperature of the oil would be so high that it would be impossible to put one's hand in it to fish for the thermometer. This was not so, and having regained the instrument, it was possible to read the temperature as 168° F., whilst the differential casing was cool enough to touch without discomfort.

Suitably impressed, I then tried to find fault with the brakes, and the complete descent was made at approximately 15 m.p.h. with the sole retarding effect being provided by the foot brake. After 5 min., the reservoir pressure had dropped to 50 p.s.i., so fourth gear was engaged for 21 min. to speed the engine up and therefore recharge the reservoir.

The descent took 9 min. and at the bottom the drums were gently smoking. Before they had time to cool off, an emergency stop from 20 m.p.h. was made and the Tapley meter gave a reading of 45 per cent.

Another check was made after 5 min. running and a reading of 47 per cent, was obtained. This reading was repeated after a further 5 min., showing that in spite of the gruelling treatment the brakes had not suffered any loss in efficiency.

Before reaching Whittington, a

halt was made to enable the test tank to be refilled for a second consumption run and during this, 15.9 miles were covered in 39 min., at the expense of 11 gal. of fuel. Traffic obstruction necessitated the use of fourth gear for one minute during this run, and the average radiator temperature was lower (155° F.) because the radiator muff had not been replaced after the climb up the Pass.

The average figure for the two runs came out at 10.05 m.p.g., which shows undoubted economy when running at over 20 tons gross weight. The road used for the consumption runs was not by any means flat and included several sharp inclines which served to accentuate the high torque of the engine at low speeds.

Darkness was beginning to fall by the time we reached Shrewsbury by pass for the short-distance trials, and the road was very wet. From 20 m.p.h., the braking distance was 38 ft., which included a certain amount of slipping due to lack of adhesion. The Tapley meter registered 47 per cent, efficiency, which provided a further check on the efficiency figures obtained after the &scent of the Pass.

From 30 m.p.h., 79 ft. were required in which to come to rest. In

view of the adverse weather conditions, these figures should not be taken as being in any way representa: tive of the true braking capacity of this vehicle, but they give some idea of the effectiveness of the braking system in the worst of circumstances.

Direct-drive acceleration tests again proved the value of the good engine torque and the figures for the standing-start tests were good by virtue of the quick changes which

were made possible with a constantmesh gearboxand a clutch stop.

The test vehicle had covered over 7,000 miles before I took it over and, being thoroughly run-in, it was at a peak of efficiency. The test showed that this Sentinel model has a healthy appetite for hard work combined with an economical fuel consumption and that the power available should be quite suitable for running as tested with a 10-ton-gross trailer.