Aluminium-alloy Bodies Increase Payload

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

SOME excellent bodies constructed in aluminium alloy are being built by Motor Bodies (1-lapton), Ltd., North Street, Manton, near Burnley, Lancashire. They are constructed entirely from aluminium-alloy extrusions supplied by the Northern Aluminium Co., Ltd., Banbury, Oxford, and are built in sections, comprising underframe, sides, bulkhead. roof, tray-rack frames and . wheel-arch boxes. All are built as sub-assemblies. and being jigged can be interchanged without difficulty.

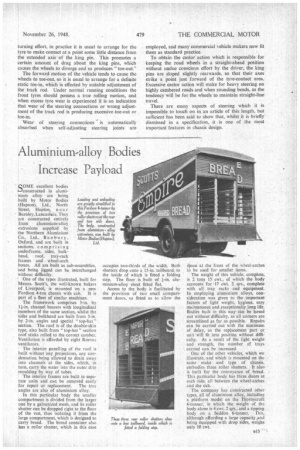

One of the types illustrated, built for Messrs. Scott's, the well-known bakers of Liverpool, is mounted on a new Fordson 4-ton chassis with cab. It is part of a fleet of similar machines.

The framework comprises 3-in, by channel bearers with longitudinal members of the same section, whilst the sides and bulkhead are built from 3-in. by 2-in, angles and special " top-hat " section. The roof is of the double-skin type, also built from " top-hat " section roof sticks rolled to the correct camber. Ventilation is afforded by eight Roevaz ventilators. .

The interior panelling of the roof is built without any projections, any condensation being allowed to drain away into channels at the sides, which, in turn, carry the water into the outer drip moulding by way of tubes.

The interior frames are built in separate units and can be removed easily for repair or replacement. The tray angles are also of aluminium alloy.

In this particular body the smaller compartment is divided from the larger one by a galvanized mesh, and its roller shutter can be dropped right to the floor of the van, thus isolating it from the large compartment, which is designed to carry bread. The bread container also has a roller shutter, which in this ease

Loading and waloading are greatly simplified in this Ford son 4-tormer by Me provision of two roller shutters at the rear and two side doors. The body, constructed from aluminium alloy extrusions, was built by Motor Bodies (Hapion),

occupies two-thirds of the width. Both shutters drop onto a 15-in, tailboard, to the inside of which is fitted a folding

step. The floor is built of aluminium-alloy sheet fitted flat.

Access to the body is facilitated by the provision of two small compartment doors, so fitted as to allow the ?pace at the front of the wheel-arches to be used for smaller items.

The weight of this vehicle, complete, is 2 tons 15 cwt., of which the body accounts. for •17 cwt. 2 qrs., complete with all tray racks and equipment. In employing aluminium alloys, consideration was given to the important factors of light weight, hygiene, easy maintenance and exceptionally long life. Bodies built in this way can be hosed out without difficulty, as all corners are streamlined as far as possible. Repairs can be carried out with the minimum of' delay, as the replacement part or unit Will fit into position without difficulty. As a result of the light weight and strength, the number of trays carried can be increased.

One of the other vehicles, which we illustrate, and which is mounted on the sarne make and type of chassis, embodies three roller shutters. It also, is built for the conveyance of bread. This particular body has three doors at each side, all between the wheel-arches and the cab.

The company has constructed other types, all Of aluminium alloy,. including a platform model on the Thoriaycroft 6-tonnet', in Which the Weight of th.-. body alone is 4 cwt. 2 qrs„ and a tipping body on a Seddon 6-tonner. This, although affording a large capacity,and being equipped with drop sides, weighs only 10 cwt.