A Novel Type of

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

Fire-escape

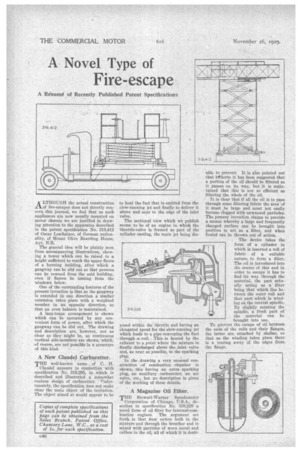

A Rdsurn4 of Recently Published Patent Specifications A LTROUGFI the actual construction 21_of fire-escapes does not directly concern this journal, we feel that as such appliances are now usually mounted on motor chassis we are justified in drawing attention to the apparatus described in the patent specification No. 319,412 of Oscar Leschziner, of German nationality, of Mount Olive Boarding House, Ayr, N.B.

The general idea will be plainly seen from accompanying illustrations, showing a tower which can be raised to a height sufficient to reach the tipper floors of a burning building, after which a gangway can be slid out so that persons can be 'rescued from the said building, even if flames be issuing from the windows below.

One of the outstanding features of the present invention is that as the gangway is extended in one direction a similar extension takes place with a weighted member in an opposite direction, so that an even balance is maintained.

A lazy-tongs arrangement is shown which can be operated by any convenient form of power, after which the gangway can be slid out. The drawing and description are, however, not as clear as they might be, as continuous vertical side-menibers are shown, which, of course, are not possible in a structure of this Rind.

A New ClaucleI Carburetter.

THE well-known name of C. H.

Claudel appears in connection with specification No. 319,295, in which is .described and illustrated a somewhat curious design of carburetter. -Unfortunately, the specification does not make clear the main object of the invention. The object aimed at would appear to be to heat the fuel that is emitted from the slow-running jet and finally to deliver it above and near to the edge of the inlet valve.

The sectional view which we publish seems to be of an engine in which the throttle-valve is formed as part of the cylinder casting, the main jet being dis posed within the throttle and having an elongated Spout for the'slow-runriing jet which leads to a pipe•conveying the fuel through La..eoil....This is heated by the exhauat to a point where the mixture is finally discharged • above' the inlet valve and, as near as possible, to the sparking plug. • the..drowing a very unusual construction of combustion chamber is • shown, this having an extra sparking Plug, an auxiliary carburettor, an. air valve, etc., but no description is given • of the working of these details.

A Magazine Oil F,ilter.

THE Stewart-Warner. Speedometer

Corporation of. Chicago, U.S.A., describes in specification No. 319,226 •a. novel form of oil filter for internal-combustion engines. The, argument set forth is that dust enters both in the mixture and through the breather and is mixed with particles of worn metal and carbon in the oil, all of which it is desir-• able to prevent. It is also pointed out that hitherto it has been suggested that a portion of the oil should be filtered as it passes on its way, but it is maintained that this is not so efficient as filtering the whole of the oil.

It is clear that if all the oil is to pass through some filtering fabric the area of it must be large and must not easily become Clogged with unwanted particles. The present invention claims to provide a means whereby a large and frequently changed surface can be brought into position to act: as a filter, and when fouled can be thrown out of action.

The device takes the form of 'a cylinder in which is inserted a roll of fabric of a suitable nature. to form a filter. The oil is introduced into the centre of. this and in order to escape it has to find its way through the material, the part actu-. ally acting as a filter being that which lies between the outer coil and that part which is winding on the central spindle. By slightly rotating the spindle, a fresh part of the material can be brought into use.

To prevent the escape of oil between the ends of the coils and their flanges, the latter are attached by shellac, so that as the winding takes place there is a tearing away of the edges from the flange.