Progress in

Page 81

If you've noticed an error in this article please click here to report it so we can fix it.

Central Lubrication

Some Details of the Alcyl System Which is Being Adopted by Important Commercial Vehicle Makers DURING recent months many _L./existing and new models have had the Alcyl central lubrication system installed, and examples were seen at the Show at Olympia on certain Albion, Karrier, Gilford and Halley chassis, to name but a few.

It will be remembered that this system consists of a tank, bolted to any convenient part of the chassis, having divisions according to the requirements of the vehicle. For example, there may be, say, five sections each feeding an equal quantity of oil to a distributing point OR the chassis, or two of the divisions may be arranged to feed a point, or group of points, which require a heavier supply than the remainder.

The tank or pipe-work used is, of' course, designed to suit the chassis, the maker of the Alcyl system, Ripaults, Ltd., 1, Ring's Road, London, N.W.1, working in co-operation. with the chassis manufacturer.

From the tank, flexible conduits run to distribution points. This conduit consists of Cistoftex tubing covered by metal armouring. Each end of the conduit Jima banjci-shaped union held in place by a trapped collar. Through each conduit runs a specially stranded wick which passes around the banjo at each end in an annular groove; the tube is thus kept filled by capillary action and air locks cannot occur.

Recent developments of this scheme include small cylindrical tanks for fitting to individual lubrication points; for example, there may be one isolated bearing, to which it would not be economical to run a conduit for a distance of, say, 10 ft. or 12 ft. The small tank is easily installed there, and a regulator jet in the base of it ensures, at all times, the correct quatttity being supplied. Another development of thi.3 method of supply consists of a special

tank and conduit sy6tem for feeding clutch-withdrawal ball races or centre bearings.

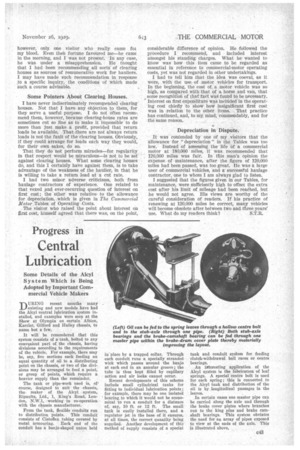

An iiiteresting application of the Alcyl system is the lubrication of leaf springs. A special centre bolt is used for each spring; this is connected to the Alcyl tank and distribution of the oil is by.longitudinal passages in the leaves.

In certain cases one master pipe can be carried along the axle and through the brake cover plates where branches run to the king pins and brake camshaft bearings. This system obviates the need for an array of pipes exposed to view at the ends of the axle; This is illustrated above.