This is the MAN-V1N range for Britain...

Page 49

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

THE MT 6.90 is rated at 6.5 tonnes gross vehicle weight, the lightest of the MAN VW commercial vehicles available in the UK. Its MAN D0224MF 3.79-litre fourstroke, direct-injection diesel engine is naturally aspirated and provides an output of 66kw (90bhp) at 3,000rpm and torque of 245nm (181Ibft) at 1,600rpm. A five-speed synchromesh gearbox with a direct-top gear ratio drives through to either a standard or heavy-duty rear axle offering a choice of three ratios providing for maximum road speeds of 100, 91 and 79km/h (62, 57 and 49mph). Its riveted, pressed steel chassis may be specified in any one of three wheelbase dimensions 3.1, 3.6 or 4.25m (10.2, 11.8 or 13.9ft) accommodating four maximum body lengths of between ,3.5m (138in) for tipper application and 5.66m (223in) for haulage. The forward-control cab has an Isringhausen driver's seat and a dualpassenger seat. Twin torsion-bar assistance makes it possible for one person to tilt the cab to its maximum 52°. Air/hydraulic dual-circuit brakes are fitted with rear-axle-load sensing to match brake performance to load conditions. Two 12-volt batteries supply the 24-volt components connected via colour-coded cable trunking.

A 100-litre fuel tank should provide a range of about 400 miles.

Two vehicles, designated 8.90F and 8.136F, are the heaviest of the. non-hgv models at 7.49 tonnes and offer a choice of power options. The 8.90F is equipped with the same four-cylinder modular engine used in the lightest vehicle in the range while the 8.136F shares an inline six-cylinder unit, rated at 100kw (136bhp) at 3,000rpm, with other models up to 10 tonnes gvw. The latter is deemed suitable for drawbar operation at 16 tons gross train weight, but only where the chassis is ordered to drawbar specification. With the largest wheelbase dimension of 4.6m (15.1ft), a longer platform length of up to 6.218m (245in) is catered for while a maximum body payload allowance for the shortest 3.1m (10.2ft) chassis is 4.524 tonnes, just 90kg (1981b) less than that for the most powerful model.

The 9.136F, a 4x2 rigid, uses the same steel cab specified with the lighter MT models. Its modular 5.68-litre six-cylinder engine, with two cylinders per head, has a bore stroke relativity of 102mm to 116mm (4.015in to 4.565in) and compression ratio of 18.1 to one, producing torque of 353nm (260bft) at 1,600rpm. Gear ratios in the five-speed box and power take-off options are identical throughout the range. The standard rear axle ratio, 4.44 to one, equates to a topgeared speed of 107.6km/h (66.9rnph) and a first-gear gradeability of 25.5 per cent. Lower speed variants of both the standard and heavy-duty axles are also available with diff lock options. Four chassis wheelbase dimensions between 3.1m and 4.6m (10.2 and 15.1ft) provide for body platform lengths of up to 6.218m (245in). The gross vehicle weight of nine tonnes is split front to rear with plated weights of 3.2 tonnes and 6.1 tonnes while the gross train weight remains at 16.25 tonnes.

Standard equipment on all MT chassis includes a side-mounted spare wheel and carrier, front bumper with recessed towing pin, wheels' stud-protection rings, tool kit, jack and body-mounting brackets.

The 4x2 10.136F is the lightest vehicle badged as an MAN. It offers a choice of wheelbase dimensions in line with the lighter MT range and similarly suits a wide range of applications when fitted with any of the diverse selection of body types ranging from drop-side tippers to insulated and refrigerated boxes.

For drawbar operation it has a gross train weight of 18 tonnes for which the six-cylinder 100kW (136bhp) engine provides a power to weight ratio of 5.5kw/tonne (7.5bhp/ton).

As a rigid unit the 10-tonne vehicle offers an attractive body payload capacity of just under 6.6 tonnes. The choice of three drive-axle ratios meets the needs of both urban and motorway operations. Last year CM returned a fuel consumption of 19.31it/100km (14.63nnpg) over 338km (210 miles) of mixed running. A pair of 100-litre (22gal) tanks as fitted to all 4.25 and 4.6m (13.9 and 15.1ft) wheelbase models up to this weight gives an operational range of around 600 miles in solo form.

The 16.240 FD and FDS models are rugged, powerful 16-tonners primarily constructed for drawbar operation. (A lighter but less powerful model will become available in the autumn). Its naturally aspirated six-cylinder 11.4-litre engine, built on the modular principle with individual cylinder heads, gives a power output of 177kw (237bhp) and tor que backup of 824Nm (608 lbft} making this vehicle admirably suited for operations up to a maximum train weight of 32.52 tonnes.

A ZF AK6-90 six-speed gearbox with a GV 90 splitter has a total of 12 forward constant-mesh gears to match the fullest operational requirements and provides for a variety of pto options.

The fully undersealed tilt cab is mounted in its own rubber suspension, and the driver's seat is equipped with a variable hydraulic suspension for maximum comfort. The sleeper-cab derivative includes two full-size curtained bunks trimmed with the same high standard as the day cab.

A standard wheelbase option of 5.5m (18ft) and the optional of 5m (16.4ft) cater for body/payloads of up to 10.57 tonnes.

The same sturdy design is adopted for MAN's lightest tractive unit as is employed with the most powerful 16-ton rigid, The installed power of its 11.4-litre MAN D2566 MF engine gives a power to weight ratio of 4.58kw/tonnes (6.23bhp/ton) at the maximum gross combination weight of 38 tonnes.

An unladen weight of 5.92 tonnes on the heavier sleeper-cab model provides for a trailer/payload of 32.08 tonnes after making allowances for incidentals such as the spare wheel, fifth-wheel coupling, oil, water and driver.

With an axle split of 6.5 and 10.17 tonnes, front to rear, the position of the fifthwheel-mounting plate is adjustable to match the trailer kingpin position. However, for maximum imposed load of 10.5 tonnes it is located 750mm (29.53in) forward of the drive-axle centre-line. Twelve gears and a choice of two rearaxle ratios give a wide operational range from a maximum gradeability of 20 per cent to a maximum geared speed of 105km/h (65mph).

For the 16.321, combined turbo charging and intercooling produces more power from the D25-Series six-cylinder engine to give and installed rating of 235kw (315bhp) for a designed operational weight of 44 tonnes. Maximum torque of 1,350Nm (995 lbft) is almost constant between 1,200 and 1,600rpm. A 13-speed Fuller RTO 11613 range-change gearbox drives through to a 4.2 to one epicyclic hub-reduction final drive to give a top geared speed of 115km/h (72mph) at maximum engine speed of 2,200rpm.

Similarly to the larger HT models, the bolted and riveted chassis side-members are shaped, so matching strength to flexibility.

The high standard of equipment inside the two-man all-steel cab includes pneumatic suspension seats, two fullsized bunks, stowage facilities and a radio. With a 3.1m (10.2ft) wheelbase it weighs in, ready for the road, at 6.05 tonnes.

A heavier, 13-tonne rear axle, stronger chassis and longer 3.5m (11.5ft) wheelbase are the main differences between this 19.321 4x2 tractive unit and its 16,321 stable-mate. Larger 9.00x22.5 wheels and 315x 80R 22.5 low-profile tyres, specified front and rear, alter the gearing slightly to give a calculated top speed of 118km/h (73mph) and increased ground clearance.

Small changes in suspension add to the height of the fifth-wheel, which is some 30mm (1.1in) higher in the laden condition. But the imposed load potential is increased from 10.5 to 12.5 tonnes with the fifth-wheel kingpin in the optimum position 500mm (20in) ahead of the drive axle, but not for UK operation.

Easier weight compatability at maximum UK limits may be provided by MAN's range of 6x2 tractive units. The 22.281 FVLT twin-steered unit is rated at 22 tonnes with imposed fifth-wheel loadings of up to 14.28 tonnes for operation at 38 tonnes gtw.

The D 2566 MKF 206kW (276bhp) sixcylinder engine drivers through a 13-speed Fuller RTO 11613 box, to a MAN rear axle with planetary hubs. Two finaldrive ratios of 4.2:1 and 4.64 to one give a working range of 30 per cent gradeability at the one end of the scale and a top geared speed of 118km/h (73mph) at the other.

Air suspension fitted to the second steered axle and drive axle can be used to raise the chassis temporarily while constant fifth-wheel height is maintained automatically on normal running. For the time being at least the most powerful MAN road-going vehicle sold in the UK is the 22.321 FVLT. In many respects it is similar to the other 6x2 tractive unit, but here the 11.41-litre D2566 MKF inline diesel engine, with combined turbocharging and intercooling, and direct fuel injection, is rated at 235kw (315bhp) with a torque capacity of 1,350nm (996Ibft) installed in the chassis.

Weighing only a few kilogrammes more, the tractive unit has an unladen weight of 7.6 tonnes fully equipped and with a sleeper cab insulated against noise and temperature. A smaller cab alternatively be specified, mounted on an identical 2.3 plus 1.3m (7.5 'plus 4.3ft) wheelbase chassis allowing a further 110kg (240Ib) in payload capacity.

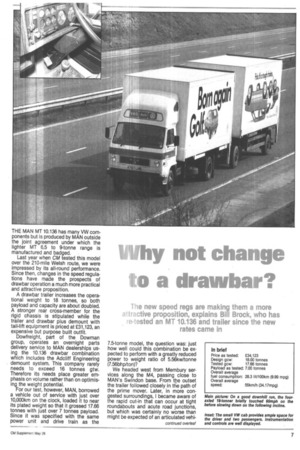

In May MAN introduced a more powerful eight wheeler alongside its existing 30.240 VFK model equipped with a 177kW (237bhp) engine. Both vehicles share a similar specification with flitch plated chassis, rear mounted anti-roll bar, inter axle differential and cross-axle differential locks but the new model, the 30.281 VFK claims to be the most powerful production eight wheeler available in Britain with a net installed power output of 206kW (276bhp). For more off road than on operation MAN produce the bonneted 32.240 DHAK. THE MAN MT 10.136 has many VW components but is produced by MAN outside the joint agreement under which the lighter MT 6.5 to 9-tonne range is manufactured and badged.

Last year when CM tested this model over the 210-mile Welsh route, we were impressed by its all-round performance. Since then, changes in the speed regulations have made the prospects of drawbar operation a much more practical and attractive proposition.

A drawbar trailer increases the operational weight to 18 tonnes, so both payload and capacity are about doubled. A stronger rear cross-member for the rigid chassis is stipulated while the trailer and drawbar plus demount with tail-lift equipment is priced at £31,123, an expensive but purpose built outfit.

Dowfreight, part of the Dowman group, operates an overnight parts delivery service to MAN dealerships using the 10.136 drawbar combination which includes the Adcliff Engineering demount system. This company rarely needs to exceed 16 tonnes gtw. Therefore its needs place greater emphasis on volume rather than on optimising the weight potential.

For our test, however, MAN, borrowed a vehicle out of service with just over 10,000km on the clock, loaded it to near its plated weight so that it grossed 17.66 tonnes with just over 7 tonnes payload. Since it was specified with the same power unit and drive train as the 7.5-tonne model, the question was: just how well could this combination be expected to perform with a greatly reduced power to weight ratio of 5.56kwitonne (7.56bh piton)?

We headed west from Membury services along the M4, passing close to MAN's Swindon base. From the outset the trailer followed closely in the path of the prime mover. Later, in more congested surroundings, I became aware of the rapid cut-in that can occur at tight roundabouts and acute road junctions, but which was certainly no worse than might be expected of an articulated vehi cle of the same 15.05m (49ft 4in) overall length.

Along the motorway section heavy rutting caused the combination to weave occasionally, but larger vehicles exerted little influence on the steering as they passed by. Once I had changed into top gear — having to overcome the drag of the two box demounts as well as the weight this understandably took longer than with most solos — I held it until I left the motorway to refuel at the Aust services before the Severn Bridge.

On good downhill sections the fouraxled 18-tonner accelerated to the maximum permitted limit of 60mph, just below the vehicle's theoretical maximum, and maintained it along the flat until the next upward gradient. Even the slightest incline was sufficient to pull the speed down, often to below 40mph. Over the first 84.6km (52.6 miles) the vehicle averaged 73.6km/h (45.7mph) working hard but never struggling.

On the dual-carriageway, up to and past Monmouth the 50mph limit was observed by all the commercial traffic we saw heading north. Although I was unable to maintain this speed constantly with the drawbar combination, where this was attainable it improved the flow of the journey; fewer down changes were necessary going up hill and fewer checkbrake applications on the descents. As some measure of how well the vehicle progressed, it took 63 seconds longer to climb Monmouth hill than it did with the solo rigid which had been limited to 40mph, but over the whole section it was faster.

Steep hills demanded full use of the five-speed synchromesh gearbox and first gear had to be resorted to on more than one occasion and always used when starting off from rest.

At 50mph the engine pulled at 2,300rpm at the top end of the green, economy sector marked on the tachometer. At 30mph in top gear, engine speed dropped to about 1,200rpm, below maximum torque by 300rpm, but continued to pull without undue labour.

The standard Rockwell 4.87 to one rear axle has now been replaced by a Volkswagen axle of 4.44 to one for solo operation, but unless an operation is anticipation a great deal of motorway running I suggest that the optional 5.57 to one ratio is a wiser choice for drawbars.

The VW cab is mounted low on the MAN MT chassis and there was very little evidence of pitch or roll. Occasionally over bumpy roads it was possible to perceive the drag imposed by the trailer, but overall there was little indication of any shunting movement through the coupling. Contending with a fully laden front axle, the standard Gemmer ZF worm and roller steering did not require the benefit of power assistance offered as an option at E606 factory fitted. For reversing, it might have been an advantage to speed up the change in steering angle. However, I believe reversing a drawbar combination is an acquired art perfected only after considerable practice.

Under normal braking the pedal felt heavy and I got the impression that the front portion of the combination was contributing a disproportionate amount of effort. On one down-hill section, the linings became quite smelly owing to repeated check-brake applications. An exhaust brake would be a worthwhile addition at this weight and would save a considerable amount of lining wear. I understand that it is an optional extra. While I have no complaint to make of the clutch operation, I believe that with the extra loading and increased number of gear changes it would be prudent to specify the larger 310mm heavy-duty option.

As yet, but not for too much longer, the 10.136 is supplied with twin 100-litre fuel tanks, the largest that VW manufactures. While a larger single tank might be more convenient, there should be no great problem with the dual system except that the tanks are separated by a manual valve. The fuel level in each of the tanks is instantly visible on the facia by means of the flick of a switch, but in order to change over from one to the other, the driver must stop, climb down and turn the lever by hand.

Use of the small, light VW cab contributes to the very good body/payload potential and has no obvious drawbacks. Its low entry lessens fatigue during local deliveries, the lsringhausen seat adds to the quality of the interior fitments, and instrumentation and controls are logically and ergonomically placed.

The cab is narrower than the allowable full width of the body, but it is wide enough to accept a sleeper pod, as the test vehicle shows. While I have heard complaints about the positioning of the mirrors, in my view and with the worst case with which to contend, I could find no grounds on which to justify them.

Fuel consumption and journey times are difficult to equate as there is no other vehicle with which I can draw a direct comparison. And since testing the vehicle solo the speed limits have changed. Over sections of the route where the speed remains the same for rigid vehicles, the drawbar was seen to be some 17 minutes slower. From Membury to Aust. where a 60mph speed limit prevails it was 15 minutes slower.

Overall the vehicle used 95.92 litres (21.1gal) but with an increased body/payload of eight tonnes, some 80 per cent, it is, I believe a fair exchange.