SIMPLE MECHANICS

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

Principles of gearing

WHEN a vehicle is travelling along a road the resistance to its motion (termed the tractive resistance) consists of: (a) Rolling resistance. This will depend mainly on the nature of the ground being traversed. A tipper operating off he road on a building site will ibviously have a greater rolling -esistance to overcome than a orry travelling along a motorway with a hard, smoothly 3aved surface.

Transmission friction, the :riction set up by the gears and Jearings in the transmission iystem, is sometimes included inder this heading.

:b) Wind resistance. This de)ends upon the size and shape )f the vehicle. Readers of CM rwill have noticed the reports of he research being carried out to .educe the wind resistance of :ommercial vehicles by fitting ;pecially shaped devices to the :abs. This is what streamlining s all about.

c) Gradient resistance. This vill depend on the steepness of he hill and the weight of the rehicle. Travelling downhill the jradient becomes something of 'bonus.

For a vehicle to travel at a iniform speed, the tractive resstance must be balanced by the ractive effort produced at the 5oint of tyre contact with the oad. For acceleration, the iriving force must be greater han the total tractive resistance.

The tractive effort required at he driving wheels to propel the fehicle varies considerably iccording to the conditions pre,ailing at any given time. If a ,ehicle is travelling at, say, 50mph on a level road, only a noderate effort or turning monent (torque) is required at the (riving wheels, but at a high ;peed of rotation

When the vehicle starts from est a large torque at low wheel .peed is necessary. This equires a fairly high engine )utput and, therefore, high enline revs. Again, when climbing steep hill, a high torque with a nodest road wheel speed is equired.

The gearbox provides the .arying gear ratios necessary to !nable the torque transmitted rom the engine to the driving wheels to be varied according to )ad and speed requirements.

The ideal would be for a radually variable gear but. exept for very light vehicles with a elt drive, this is not practicable and generally four, five or six different ratios are available.

These may be augmented on heavy vehicles by splitter gears or by two speed axle, both of which double the ratios avail able in the main gearbox.

The gearbox also provides a neutral position, allowing the engine to run with the clutch engaged and the vehicle stationary, and a reverse gear enab ling the vehicle to travel backwards.

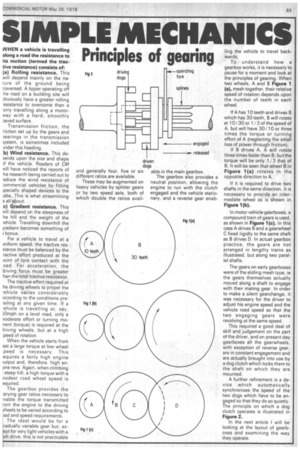

To understand how a gearbox works, it is necessary to pause for a moment and look at the principles of gearing. When two wheels, A and B Figure 1 (a), mesh together, their relative speed of rotation depends upon the number of teeth in each wheel.

If A has 10 teeth and drives B which has 30 teeth, B will rotate at 10/ 30 or 1 /3 of the speed of A, but will have 30/10 or three times the torque or turning effort of A (neglecting the small loss of power through friction).

If B drives A, A will rotate three times faster than B, but the torque will be only 1/3 that of B. It will be seen that wheel B in Figure 1(a) rotates in the opposite direction to A.

If it is required to drive two shafts in the same direction, it is necessary to provide an intermediate wheel as is shown in Figure 1 (b).

In motor vehicle gearboxes, a compound train of gears is used, as shown in Figure 1(c). In this case A drives B and a gearwheel C fixed rigidly to the same shaft as B drives D. In actual gearbox practice, the gears are not arranged in lengthy trains as illustrated, but along two parallel shafts.

The gears on early gearboxes were of the sliding mesh type, ie the gears themselves actually moved along a shaft to engage with their mating gear. In order to make a silent gearchange, it was necessary for the driver to adjust his engine speed and the vehicle road speed so that the two engaging gears were revolving at the same speed.

This required a good deal of skill and judgement on the part of the driver, and on present day gearboxes all the gearwheels, with exception of reverse gear, are in constant engagement and are actually brought into use by a dog clutch which locks them to the shaft on which they are mounted.

A further refinement is a device which automatically synchronises the speed of the two dogs which have to be engaged so that they do so quietly. The principle on which a dog clutch operates is illustrated in Figure 2.

In the next article I will be looking at the layout of gearboxes and examining the way they operate.