Perkins power cuts world costs

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

OMMERCIAL VEHICLES owered by British-built or :ritish-designed diesel en pines are playing a big part in :eeping the developing :ountries of the world on the nova.

The pattern of progress owards the use of diesels is traightforward. the first step is isually conversion from iasoline to diesel; later comes he installation of imported kitish diesels in new home-built quipment; next diesels are

issembled locally from -nported engine kits and instalad; finally, where the market lemands it, locally built cornionents are manufactured and liesels built for the home and ,ften the native country's export narkets.

Perkins have experienced his pattern. In most cases the 'erkins six-cylinder 6.354 is the ,ngine involved: in Central kmerica and Chile, for example, he big story to tell is converion; in the Philippines, Interntional Harvester installs Britishiuilt and imported diesels in )rries built in Manila; in Peru, ngine kits are assembled for istallatton in Chryslers; in lrazil, Mexico and the Argenine, manufacturing facilities iuild complete engines.

Over and above this pattern, omplew Perkins diesel-powred vehicles are exported to the developing world, Nowhere is this more apparent than in the Arabian Gulf. Major new roads being built rely on the services of, for example, Perkinspowered Haulamatics, Dodge, Ford, British Leyland and many other commercial vehicles.

But first let's look at the pattern in Central and South America.

In Colombia, Perkins distributor Casa Inglesa has done many conversions — it has even put a Perkins V8 diesel into a 1935 Scammell lorry(!). In Barranquilla the Sobusa bus line has a number of Avia buses brought into the country with Perkins six-cylinder engines.

In Nicaragua the way has been led by Alfredo Cuevas who, in his Managua El Triunfo workshop has carried out more than 1,000 conversions since he started in 1965.

Sr Cuevas can show enormous personal savings the price of diesel fuel is a third less than gasoline, which is a bonus to be added to the engine's economy. Other savings are on maintenance, on the fact that no replacement engine is necessary during the average vehicle's life and even on comparative tradein value.

All this gives Sr Cuevas a cost saving with diesel, over a seven-year period, of US16,000 on each bus. A Chilean operator runs four International Harvester buses, two with petrol engines and two with Perkinsdiesels. hisdaily fuel bill on diesels is less than half that of the fuel bill for the petrol units. Each bus covers more than 230km a day and while his petrol costs him SUS29.20 a day a bus, his diesel fuel comes to only SUS14.20.

The initial conversion breakthrough in Peru came with buses carrying workers to and from Lima's outlying factories: two major and many smaller fleets operate Perkins-powered buses for this job.

The regular bus fleets followed suit, and then came the lorry business, with the decision of Chrysler del Peru to install the Perkins altitude compensated C6.354 in the D500 truck.

The C6.354 was designed for use in Peru, Colombia, Venezuela, Bolivia and Ecuador and the concept was to preserve sea level power at altitude through torque modification.

Chrysler carried out an exhaustive test. Two vehicles, one with petrol engine and one with the C6.354 were fully laden and set off down Peru's Central Highway, into the Andes. Up to 4,500ft altitude the petrol version was ahead; at 6.000ft the diesel lorry had caught it up . . and at 8.500ft the Perkins diesel-powered vehicle was a long way in front. Now Perkins and Volvo, in conjunction with the lnduperu

and Corfide government organ:, isations, have launched a factory where, of the 15,000 engines to be built annually, 10,000 will be Perkins, supplying initially Chrysler, Tractores Andinos, and other local manufacturers and distributors.

In Uruguay, Perkins Rio de la Plata has a new, if small, factory; Perkins diesels there are best known for the more than 500 cabs operating in the capital city.

In Argentina, Brazil and Mexico, Perkins diesel engines, manufactured with locally made components by successful companies in these countries for many years, are accepted power units in a wide range of vehicles.

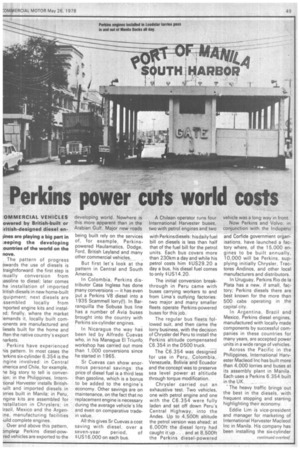

Across the Pacific in the Philippines, international Harvester Macleod Inc has built more than 4,000 lorries and buses at its assembly plant in Manila. Each uses a Perkins 6.354 built in the UK.

The heavy traffic brings out the best in the diesels, with frequent stopping and starting highlighting their economy.

Eddie Lim is vice-president and manager for marketing of International Harvester Macleod Inc in Manila. His company has been installing the six-cylinder 6.354 (known in the Philippines as the D.354) in its vehicles since the early 1960s. Does IHM have any problems? Only when some of the operators overload both lorries and buses, causing strain on engine and springs.

Diesel economy stories with figures to back them up are as common in South East Asia as elsewhere: take the Merantama bus fleet in Jakarta, Indonesia. With the diesel's natural economy being boosted by fuel for petrol engines costing almost three times as much, its not surprising that operators use diesel.

The Merantama, a private company, operates 147 buses powered by the Perkins 6.354 six-cylinder vehicle diesel engine and 98 buses powered by petrol engines. The diesel engine uses 35 per cent less fuel.

This table shows the annual saving on one diesel-powered bus compared to one petrolengined bus: Distance travelled per bus 42,250 miles Consumption of diesel fuel 5,148gal Consumption of petrol 7,865gal Cost of diesel fuel at 25rp/litre £825 Cost of gasoline at 70 rp/litre £3,216 Cost saving of diesel engine £2,700 Finally, let's look at the Middle East. The building of a new highway in the Sultanate of Oman involved cutting through huge rock mountains. Haulamatic dump trucks with Perkins V8s were used.

In desert work, diesels face the problem of extremely fine dust which demands a high standard of air filtration and frequent service maintenance. The other story is one of the most interesting conversion jobs anywhere in the world. It is carried out by the American giant oil company ARAMCO operating from an enormous base at Dhaharan in Saudi Arabia.

The search for oil is a neverending operation. ARAMCO operates a fleet of desert exploration vehicles and a fleet of supply vehicles. Both fleets include more than 50 Perkins' diesel-powered vehicles.

The supply fleets travel the desert to keep ARAMCO outposts stocked. The exploration fleets carry seismological research teams. The vehicles are all-important — the lives of so many men rely on them.

They are Dodge/ Fargo W300, W500 and W600 lorries which ARAMCO buys with petrol engines, but runs a continuous 'conversion-to-d programme. They do this because of the diesel's reliability in service, ease of maintenance and because of the fuel's low volatility in tropical conditions.

The company also prefers to standardise all its "deep desert" equipment and machinery on one type of engine.

The engine ARAMCO has

chosen for this work is the Pe kins 6.354 and the princim reason for the choice is engin torque of 2701b-ft (SAE 262) 1,200rev /min, which is exact' 'right for the arduous dese conditions.

Humood Humaidi, who foreman of light vehicle rnainti nance for ARAMCO, finds th diesels give him little trouble.

Another who is deeply ir volved with diesels is Abdi Wahal who, as maintenanc foreman, exploration depar ment, is instrumental in th special design adopted h ARAMCO for vehicles in its e ploration fleet. A third man coi cerned and satisfied with h engines is Mohammed Areel superintendent, land -transpo tation, maintenance division.

Many of the 25 vehicles ii volved in exploration alone ai built to ARAMCO's own desic and based on the Perkins si cylinder diesel. These incluc the C136ggy, a vehicle designE to operate over 800ft high sar mountains. They may cover to 3,000 desert kilometres one round trip, operating in wilderness without any vehic tracks whatever.

Most of this story has deewith diesels built in the UK ar exported either as finished e gines or as engine kits.

Perkins build about a quart, of a million diesels a year in UK at Peterborough, and te remainder of the company nearly 600,000 a year throut wholly owned, associate ar licensee companies in mei than a dozen other countri( around the world.

With all these engines beir built to the same Perkins desig maintenance, service and par replacement are much mo straightforward for operators the developing countries • understand and handle their e gines.