FORD 01000 16-TON-GROSS FOUR-WHEELER

Page 54

Page 55

Page 56

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

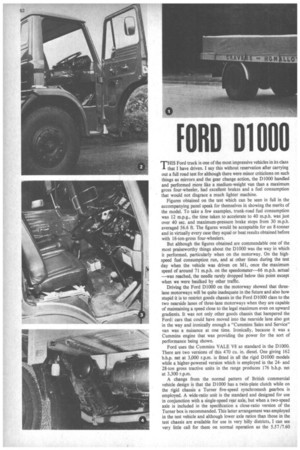

THIS Ford truck is one of the most impressive vehicles in its class

that I have driven. I say this without reservation after carrying out a full road test for although there were minor criticisms on such things as mirrors and the gear change action, the D1000 handled and performed more like a medium-weight van than a maximum gross four-wheeler, had excellent brakes and a fuel consumption that would not disgrace a much lighter machine.

Figures obtained on the test which can be seen in full in the accompanying panel speak for themselves in showing the merits of the model. To take a few examples, trunk-road fuel consumption was 12 m.p.g., the time taken to accelerate to 40 m.p.h. was just over 40 sec. and maximum-pressure brake stops from 30 m.p.h. averaged 56.6 ft. The figures would be acceptable for an 8-tonner and in virtually every case they equal or beat results obtained before with 16-ton-gross four-wheelers.

But although the figures obtained are commendable one of the most praiseworthy things about the D1000 was the way in which it performed, particularly when on the motorway. On the highspeed fuel consumption run, and at other times during the test day when the vehicle was driven on Ml, once the maximum speed of around 71 m.p.h. on the speedometer-66 m.p.h. actual —was reached, the needle rarely dropped below this point except when we were baulked by other traffic.

Driving the Ford D1000 on the motorway showed that threelane motorways will be quite inadequate in the future and also how stupid it is to restrict goods chassis in the Ford D1000 class to the two nearside lanes of three-lane motorways when they are capable of maintaining a speed close to the legal maximum even on upward gradients. It was not only other goods chassis that hampered the Ford: cars that could have moved into the nearside lane also got in the way and ironically enough a "Cummins Sales and Service" van was a nuisance at one time. Ironically, because it was a Cummins engine that was providing the power for the sort of performance being shown.

Ford uses the Cummins VALE V8 as standard in the D1000. There are two versions of this 470 cu. in. diesel. One giving 162 b.h.p. net at 3,000 r.p.m. is fitted in all the rigid D1000 models while a higher-powered version which is employed in the 24and 28-ton gross tractive units in the range produces 176 b.h.p. net at 3,300 r.p.m.

A change from the normal pattern of British commercial vehicle design is that the D1000 has a twin-plate clutch while on the rigid chassis a Turner five-speed synchromesh gearbox is employed. A wide-ratio unit is the standard and designed for use in conjunction with a single-speed rear axle, but when a two-speed axle is included in the specification a close-ratio version of the Turner box is recommended. This latter arrangement was employed in the test vehicle and although lower axle ratios than those in the test chassis are available for use in very hilly districts, I can see very little call for them on normal operation as the 5.57 /7.60 gearing on the test vehicle provides for a gradient ability of around 1 in 4.

Steering throughout the D1000 range is power assisted by a Hydro steer ram and this was found to be a very good design with just the right amount of assistance so that "feel" was always present. There was sufficient heaviness on small deflections of the wheel to obviate any tendency to over-correct when following a straight line.

The D1000 was introduced on April 28 this year and was fully described in COMMERCIAL MOTOR on that date. The actual model provided for test was the 15ft. 8in. wheelbase version and this had a Cravens-Homalloy light-alloy body with a 19ft. 6in, long platform. The load for the test consisted of iron weights tightly located on the platform and boxed in to prevent any possible movement during brake tests with resultant damage to the headboard. It was obvious that a fair amount of trouble had been taken in placing the weights because the front and rear axle loadings were exactly as the figures appearing on the "plate"-6 and 10 tons respectively.

This once again highlighted the problem that operators of "plated" vehicles are going to have when no allowance for unequal loading is made by the manufacturer. It would be almost impossible for a driver to ensure that his load was giving the correct axle loads. And unless some allowance is given by "plating" for more than 6 tons on the front axle in the case of maximum-gross four-wheelers, there is certain to be axle overloading unless a reduced grossweight is worked to.

The Ford front axle is designed for 6.3 tons but the company could not plate for this figure without 'increasing the tyre size beyond the 10.00-20, 16 ply or radial steel cord tyres standard on the model.

A good deal of rain fell on the day the tests were carried out which made brake testing difficult and because the roads were very wet early in the morning, fuel consumption was checked first. For the normal-speed runs the usual 6-mile out-and-return circuit of A6 south of Luton was used and the 12.0 m.p.g. was obtained at the very good average speed of 37.1 m.p.h. On this run 40 m.p.h. was aimed for where practicable and the only drop in speed occurred on the fairly severe gradient near the turn-round point where the sole downward gearchange on the run was necessary.

After the trunk-road-type fuel consumption check, a motorway test was carried out and this was made on M1 from the A6 junction to the A4147 turn and back. The 15.1-mile journey was completed at the very good average of 52.5 m.p.h. and when the reductions in speed necessary at the turn-round point and at the roundabout going from the spur road for A6 are taken into account it will be seen that the Ford was running at or near its maximum speed the whole way.

The section of MI used is probably the most severe of any motorway in Britain and includes fairly severe gradients on the stretch near A5. Fully laden 16-ton-gross vehicles are generally brought down to about 35 m.p.h. on the slope north of A5 when on the return run but the speed of the D1000 did not drop below an indicated 53 m.p.h.

It was fortunate that on the high-speed run traffic on Ml was light and there was no baulking from other vehicles. Later in the day, traffic hampered progress considerably when checking maximum gear speeds on the MI. These were found to be 9, 17, 28, 42 and 48 m.p.h. in low-axle ratio and 11.5, 21, 38, 57 and 66 m.p.h. in high.

The figures take into account a speedometer inaccuracy which varied between 2 per cent at 30 m.p.h. and 6 per cent at an indicated 71 m.p.h. and it will be seen from them that with the transmission and axle arrangement as on the test vehicle the change sequence with "splitting" is not successive gearbox ratios with alternate low and high axle ratios right through the range. In the two higher gearbox ratios, the sequence is fourth /low then fourth /high, fifth / low and finally fifth /high.

It is interesting that the consumption results obtained with the D1000 were almost identical to a 16-ton-gross four-wheeler with a Cummins V8 engine tested previously, even though this had a single-speed rear axle with a ratio of 7.2 to 1. The same applies to the acceleration times for the two chassis. A number of runs were made to decide the best gearbox /axle change sequence before the times quoted in the table were obtained.

I feel that better times would have been produced if there had not been some slight difficulty in changing into second gear from first. There was more resistance to the engagement of second than the other ratios, but as is common with a synchromesh gearbox on a heavy vehicle there was not the well-defined "gate" that there is with a constant-mesh box. The through-the-gears times are nevertheless very good and so are those obtained on direct drive runs, although it was asking a lot to expect the Cummins engine to pull away from 10 m.p.h. Even with low-axle ratio this speed represented an engine speed well below the idling figure—at 800 r.p.m., rather high on a test vehicle. But this was done with very little fuss.

Eventually a road was found that was suitable for brake tests and even though not bone dry, was sufficiently so for the purpose. Better figures than any previous 16-tortner tested by COMMERCIAL Motor were obtained despite some rear-wheel locking. Heavy marks were left by the rear wheels for about 3 ft. on the 20 m.p.h. maximum-pressure stops and for some 9 ft. from 30 m.p.h. Only faint marks were left by the front tyres—for most of the stopping distances—indicating that the front brakes were giving the optimum efficiency relative to the particular road surface. The 'slight imbalance between the front and rear brakes that was apparent is not necessarily a bad thing as it allows for some reduction in performance of the rear brakes (through wear for example) before efficiency is reduced to any significant degree.

There was no feeling of delay in brake application and the figures give average efficiencies for the stops of 53 per cent as compared with peak efficiencies of 81 per cent from 20 m.p.h. and 79 per cent from 30 m.p.h. recorded by Tapley meter.

Ford provides more than the minimum secondary-system requirements with the brakes of rigid D1000 models because in addition to a "split" service brake (independent actuation of brakes at each axle) which would probably comply with the Construction and Use Regulations, application of the handbrake also applies the brakes all round.

The mechanical linkage to the rear units is power-assisted by a diaphragm acutator acting on a relay lever and as air is fed to this on application of the handbrake lever, pressure is also fed to the diaphragms of the dual actuators at the front axle.

The D1000 handbrake is a single-pull type mounted on the dash and I found it necessary to be very precise in operating the unit to release the brakes fully. When applied, the lever can be returned to its original position against the dash which allows for easy access across the cab, and to release the brakes it is pulled on again to release the ratchet and then returned to the dash. I found that I was frequently not doing the job properly and leaving the brakes still applied but fortunately a warning light is provided so that this was obvious.

As will be seen from the test-results panel the really excellent time of 3 min. 47.2 sec. was returned for a maximum-power climb of Bison Hill which was used for gradient-performance checks. For most of the time spent in first /high the engine was running close to its maximum speed, the minimum road speed on the test of 10 m.p.h. being only a little below the maximum in that gear. It was not surprising with the engine running at high speed for a good part of the run that there was virtually no change in the position of the needle on engine-coolant temperature gauge during the ascent; ambient temperature on the day was 11 deg. C. (52 deg. F.).

The fade test showed that there should be no problem in this respect with the brakes on the model as tested and stop-and-restart tests on Bison gave equally good results. The handbrake had plenty in hand on 1 in 6.5 with the lever released to ensure that air pressure was exhausted from the actuating chambers leaving a purely mechanical hold at the rear only. A restart up the gradient in first high was straightforward but when facing down, clutch slip had to be induced to get the truck to start off satisfactorily in reverse /high up the slope.

I have already said that driving the D1000 has much of the character of driving a van and this was not only so from a performance aspect but also the result of the level of comfort for the driver and in general lightness of the controls. A lot of work has been done by Ford in conjunction with Cummins in developing the V8 for use in the D1000 range. Much of this has been concerned with reduction of noise and the test vehicle was certainly as quiet inside the cab as the D800 with Ford 360 cu. in. engine that I tested in 1965. That chassis had the "Custom" tilt cab with a higher quality trim than the standard version. Only the Custom cab is employed on the D1000 and this comes with a wellupholstered driver's seat and twin-passenger seat. The driver's seat is provided with a good range of adjustment but I felt that the seat for passengers was on the small side for two heavily-built men. On checking, I discovered that the width is comparable with other two-man seats in current British cabs.

All-round visibility from the driver's seat is very good and the windscreen wipers clear an adequate area. When first taking over the truck I found it necessary to reposition the mirrors which were as the standard layout with triangulated arms mounted above and below-the door windows. But even though this gave some improvement in rear vision, I never felt it was ideal primarily because the mirrors have flat glasses and did not give a really adequate field of vision. I personally prefer convex mirrors and this is particularly desirable when there is some vibration of the mirrors as I found on the Ford.

Access to the cab is easy with the forward-entrance steps lft. I lin. from the ground in the laden condition and the floor of the cab lft. 3in. above them. There is a handle on the passenger's side and I thought that one should also have been fitted on the offside to save the driver having to get %old of the wheel when getting into the cab. No criticism can be wde about the quality of the cab interior which is finished to a hi2gh standard and a comprehensive range of instruments is provided. Two useful items are a voltmeter which shows the state of the battery charge and an engine rev counter which allows the driver to make the best use of engine and transmission. Windscreen washers and a heater are standard features.

The Ford cab tilts forward for access to the power unit but routine jobs such as water and oil checks can be made through an access trap behind the driver's seat; this seat tilts forward to make this easier.

It would be difficult to get a better power-steering layout than that used on the D1000 for this gave the "feel" of an unassisted steering box with a lightly-loaded front axle. And the suspension was also very good, being soft and well damped at the front end.

Two of the most important things shown by this test of the Ford D1000 are that the Cummins VALE V8 engine can give excellent fuel economy and that the use of a relatively high-powered engine does not necessarily result in poor fuel consumption. Even if the advantages of having a fast and high performance vehicle are lost by it being parked on lay-bys and outside cafes for that much longer, the level of fuel usage indicated is worth while on its own.

Empty tests were not possible because of the permanent nature of the load but I would expect between 13 and 14 m.p.g. for trunk road running and about 11 m.p.g. on high-speed journeys in the unladen condition. And if the performance is used to advantage the D1000 can be a really worth-while proposition.

The 15ft. 8in. wheelbase D1000 as tested has a basic list price for the chassis cab of £2,585. Extras fitted to the test vehicle included the Eaton two-speed axle at £160, spare wheel, carrier, hydraulic jack and handle at £66, brake anti-freeze equipment, £8 and a Varivane automatic radiator shutter at £25. These bring the total value of the Ford part of the test vehicle to £2,844 and the price of the Cravens-Homalloy body was £360 10s.