A Hollow Front Axle

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

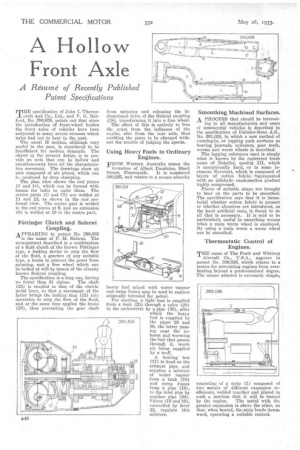

A Re'suine of Recently Published Patent Specifications THE specification of John I. Thornycroft and Co., Ltd., and V. G. Parford, No. 390,838, points out that since the introduction of front-wheel brakes the front axles of vehicles have been subjected to many severe stresses which axles had not to bear in the past.

The usual H section, although very useful in the past, is considered to be insufficient for modern demands. The object ot the present design is to provide an axle that can be hollow and simultaneously have all the characteristics necessary. The drawings show an axle composed of six piece, which can b.: produced by drop stamping.

The plan view shows the end pieces (1 and la), which can be formed with bosses for bolts to unite them. The centre parts (C and Cl) are welded at 11 and 12, as shown in the end sectional view. The centre part is welded to the end pieces at 9, and an extension (8) is welded at 10 to the centre part.

Fottinger Clutch and Salerni Coupling.

APPEARING in patent No. 390,858 is the name of P. M. Salami. The arrangement described is a combination of a fluid clutch of the known Ftittinger type, a locking device to stop the flow of the fluid, a gearbox of any suitable type, a brake to prevent the gears from spinning, and a free wheel which can be locked at will by means of the already known &demi coupling.

The specification is a long one,, having no fewer than 31 claims. The shaft (25) is coupled to that of the clutchpedal lever, so that a movement of the latter brings the locking ring (13) into operation to stop the flow of the fluid, and at the same time applies the brake (29), thus preventing the gear shaft from spinning and releasing the bidirectional drive of the Salami coupling (38), transforming it into a free wheel.

The effect of this is entirely to free the gears from the influence of the engine, also from the rear axle, thus enabling the gears to be changed without the trouble of judging the speeds.

Using Heavy Fuels in Ordinary Engines.

FROM Western Australia comes the invention of Albert Baudains, Short Street, Fremantle. It is numbered 390,225, and relates to a means whereby heavy fuel mixed with water vapour and sump fumes may be used in engines originally intended for petrol.

For starting, a light fuel is supplied from a tank (25) through a valve (29) to the carburetter by a pipe (30), after which the heavy Fuel is supplied by 390,858 the pipes 28 and 30, the latter passing near the exhaust and warming the fuel that passes through it, warm air being supplied by a muff.

A heating box (17) is fixed on the exhaust pipe, and supplies a mixture of water vapour from a tank (15) and sump fumes from a pipe (19), to the inlet pipe by another pipe (24). Valves (18 and 19), controlled by lever 22, regulate this mixture. Smoothing Machined Surfaces.

A PROCESS that should be interest

ing to all manufacturers and users of commercial vehicles is described in the specification of Daimler-Benz A.G., No. 391,058, in which a new method of running-in, or lapping such surfaces as hearing journals, cylinders, gear teeth, worms and worm wheels is described.

The lapping substance used is simply what is known by the registered trade name of Bakelite, quality III, which is exceptionally hard, or in some instances Novotext, which is composed of layers of cotton fabric.. impregnated with an aldehyde condensation product highly compressed.

Pieces of suitable shape are brought to hear on the parts to be smoothed. The specification says that it is immaterial whether cotton fabric is present or whether abrasives are introduced, as the hard artificial resin is -found to do all that is necessary. It is said to be particularly useful in smoothing worms when a resin worm wheel is employed. By using a resin worm a worm wheel can be smoothed.

Thermostatic Control of Engines.

THE name of The Pratt and Whitney

Aircraft Co., "U.S.A., appears in patent No. 389,526, which relates to a means for preventing engines from overheating beyond a predetermined degree. The means adopted is extremely simple,

consisting of a strip (1) composed of two metals of different expansion coefficients, welded together and placed in such a position that it will be heated by the engine. The metal with the greater expansion is above the other, so that when heated, the strip bends downward, operating a suitable control.