Articulated Trailers Designed for Safety

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

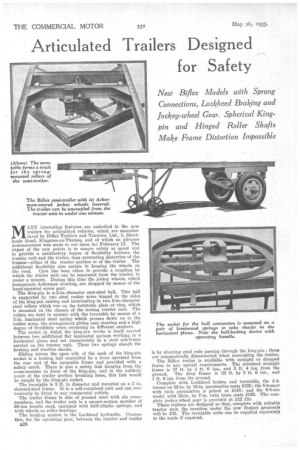

New Biflex Models with Sprung Connections, Lockheed Braking and Jockey-wheel Gear. Spherical Kingpin and Hinged Roller Shafts Make Frame Distortion Impossible MANY interesting features are embodied in the new trailers for articulated vehicles, which are manufactured by Iliflex Trailers and Tractors, Ltd., 1, Shortlauds Road, Kingston-on-Thames, and of which an advance announcement was made in our issue for February 17. The object of the new points is to ensure safety at speed and to provide a satisfactory degree of flexibility between the tractor unit and the trailer, thus preventing distortion of the frames—either of the tractor portion or of the trailer. The additional flexibility also assists in keeping the wheels on the road, Care has been taken to provide a coupling by which the trailer unit can he separated from the tractor in under a minute. During this time the jockey wheels, which incorporate Ackerman steering, are dropped by means of the hand-operated screw gear.

The king-pin is a,3-in.-diameter cast-steel ball. This ball is supported by two steel rocker arms hinged to the sides of the king-pin casting and terminating in two 8-in.-diameter steel rollers which run on the turntable plate or ring, which is mounted on the chassis of the towing tractor unit. The rollers are kept in contact with the turntable by means of a 3-in, laminated steel spring which presses down on to the rocker arms, the arrangement giving easy steering and a high degree of flexibility when cornering on different cambers.

The socket in which the king-pin works is itself carried between two additional flat laminated springs working in a horizontal plane and set transversely in a steel sub-frame carried on the tractor unit. These two springs absorb the braking and tractive shocks.

Sliding across the open side of the neck of the king-pin socket is a locking bolt controlled by a lever operated from the rear end of the turntable frame and provided with a safety catch. There is also a safety link hanging from the cross-member in front of the king-pin, and in the unlikely event of the trailer portion breaking loose, this link would be caught by the king-pin socket.

The turntable is 3 ft. in diameter and mounted on a 3 in. channel-steel frame. It is a self-contained unit and can conveniently be fitted to any commercial vehicle.

The trailer frame is also of pressed steel with six crossmembers, and the trailer axle is a square-section member of 50-ton tensile steel, equipped with half-elliptic springs, and with wheels on roller bearings.

The braking system is the Lockheed hydraulic. Connection, for the operating gear, between the tractor and trailer E28 is by abutting steel rods passing throng,h the king-pin ; these are automatically disconnected when uncoupling the trailer.

The Biflex trailer is available with straight or dropped frame to any special requirements. The standard straight frame is 17 ft. by 3 ft. 6 ins., and 3 ft. 4 ins, from the ground. The drop frame is 22 ft. by 3 ft. 6 ins., and 1 ft. 6 ins, from the ground.

Complete with Lockheed brakes and turntable, the 3-4tanner on 32-in. by 16-in, pneumatics costs £125; the 5-tonner with twin pneumatics is priced at £145; and the 6-8-tori model with 32-in. by 7-in, twin tyres costs £185. The complete jockey-wheel gear is provided at £12 12s.

These trailers are designed so that, complete with suitable tractor unit, the taxation under the new Budget proposals will be £35. The turntable units can be supplied separately to the trade if required.