REPAIRING PETROL VEHICLES.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

Ideas Suggested by Our Driver and Mechanic Readers.

IN the course of an ordinary day's work in the repair shop there are many small points which crop up with regard to methods of procedure, and a solution fomthe problem in hand is not always readily forthcoming. The experience of others in this connection may be useful, and, therefore, we describe a few of the suggestions sent in by our readers dealing with a variety of jobs.

Relining a cone clutch is not such a frequent occurrence nowadays as in past years, owing largely to the improved lining materials used, but when the necessity arises difficulty is frequently experienced with regard to methods of cutting a new lining to fit. " W.F.H.," of Basingstoke, to whom this week's prize of 15s. is awarded, describes the plan which he follows.

The first requisite is a piece of stout brown paper of sufficient length to wrap round the clutch cone, the width being slightly greater than that of the lining which is in position. After applying the paper to the cone and fixing it firmly so that it cannot move, both edges are tapped with a hammer, in a similar manner to that used when cutting out a brown-paper gasket for a joint. In this way the surplus brown paper is cut away, leaving the strip of brown paper, which exactly fits over the worn-out lining, giving the width which must be allowed for the new material. The paper is then removed, and it will be found to be curved to the proper radius of the lining. The template is laid upon a board and a series of stout wire nails driven into the board about 1-1 ins, apart, in such a manner that they just clear the paper strip. In this way the paper is kept in position, but is mit rigidly fixed to the board.

The replacement lining strip of the correct width is heated up in an oven until it reaches the necessary degree of flexibility, and it is then bent until it fits into the channel formed by the nails on the board. In order to remove any projections or proud spots on the lining It is well hammered. A point worth remembering is that the lining should be slightly longer than the paper template ; this excess length should be equal to one thickness of the lining employed.

REMOVAL of a detachable cylinder head, particularly when it is of a heavy type, is not alwayA easily accom

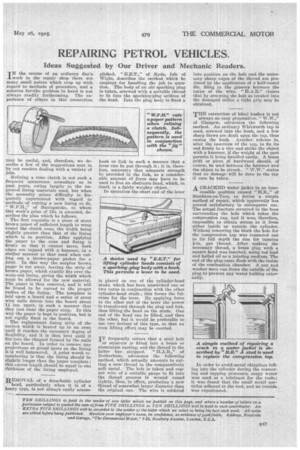

plished. "E.E.T.," of Ryde, Isle of Wight, describes the method which he employs for handling the job in question. The body of an old Sparking plug is taken, screwed with a suitable thread to fit into the sparking-plug orifices of the head. Into th3 plug body is fixed a

hook or link in such a manner that a lever can be put through it ; it is, therefore, necessary that adequate strength bo provided in the link, as a considerable amount of force may have to be used to free an obstinate head, which, in itself, is a fairly weighty object.

In operation the short end of the lever

is placed on one of the cylinder-head studs, which has been unscrewed one or two turns in conjunction with the other cylinder-head studs; this forms the fulcrum for the lever. By applying force to the other end of the lever the power is transferred through the plug and link, thus lifting the head on the studs. One end of the head can be lifted, and then the other, but it would be preferable to use two devices of this type, so that an even lifting effort may be exerted.

IT frequently occurs that a steel bolt or setscrew is fitted into a brass or aluminium casting, and the thread in the latter has stripped. " " of Rotherham, advocates the following method, which actually amounts to cutting a new thread in the comparatively soft metal. The bolt is taken and copper wire of a suitable gauge to fit into the thread grooves is wound round tightly, thus, in effect, producing a new thread of somewhat larger diameter than the original one. The wire is soldered into position on the bolt and the necessary sharp edges of the thread are produced by the application of a half-rouad file, filing in the grooves between the turns of the wire. " MAE." claims that by screwing the bolt so treated into the damaged orifice a tight grip may be obtained.

THE extraction of blind bushes is not

always an easy proposition. " W.W.," of Glasgow, advocates the following method. An ordinary Whitworth tap is used, screwed into the bush, and a few sharp blows are dealt upon the tap, thus easing the bush. Another scheme is, after the insertion of the tap, to fix its end firmly in a vice and strike the object with a hammer, if the weight of the part permits it being handled easily. A brass .drift or piece of hardwood should, of course, be used between the hammer and the object to be struck. " WAY." states that no damage will be done to the tap if care be taken.

A CRACKEt) water jacket in an inac cessible position caused " H.R.," of Stockton-on-Tees, to devise a simple method of repair, which apparently has proved satisfactory in subsequent use. The actual fracture occurred in the boss surrounding the hole which takes the compression tap, and it -was, therefore, impossible to obtain access to it from either inside or outside the cylinder. Without removing the block the hole for the compression tap was reamered out to its full depth the size for tapping fin, gas thread. After making the necessary thread, a brass plug with a square head was inserted, using red lead and boiled oil as a jointing medium. The end of the plug came flush with the inside of the combustion chamber. A nut and washer were run down the outside of the plug to prevent any water leaking externally.

In order to avoid metal chippings falling into the cylinder during the reamerjug and tapping processes, soapy water was used as a lubricant for the. tools; it was found that the small metal particles adhered to the tool, and no trouble was experienced.