WHAT WE VE TO ROAD RESEARCH

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

Working in Close Collaboration with the Ministry of Transport, the Road Research Laboratory at Harmondsworth is Carrying Out Invaluable Work in Investigating the Problems of Road

Construction

WITH the development of our highways, there has come the need for research into the manifold . problems of the science of road design and construction. This need has been met by the setting up, some years ago. of a separate branch of the Department of Scientific and Industrial Research, aiming at the formulation of a science of road engineering as a constructional process, so that materials can be used in the most efficient manner and with the greatest possible economy.

At the Road Research Laboratory at Harmondsworth there is much of vital interest to the highway engineer, and the dual problem of improving constructional methods and, at the same time, reducing the necessary expenditure to the minimum, is being pursued with the utmost vigour. The question of road safety is also the subject of close study and the measurement of the nonskid properties of road surfaces is being tackled by the _ use of a highly practical and efficient apparatus.

The research department works in close touch with the Ministry of Transport and, whilst the latter is responsible for the laying of experimental road sections on many by-passes and elsewhere, a wide variety of experiments and tests on these sections is carried out• by the staff of the laboratory.

Laboratory Tests Essential.

Although much valuable information can be culled from a study of these experimental sections under actual service conditions, their use has a number of disadvantages. A primary drawback is the time factor, for it is obvious that a road constructed of normal materials and properly laid, will last several years under the heaviest traffic conditions before failures become apparent. There is also the difficulty of computing, with any degree of accuracy, the amount of wear that the road has actually suffered. •

The Research Department has, therefore, developed a series of road machines designed to enable road materials, in sufficiently large quantities to form repre

B8 sentative samples, to be tested and measured for their durability under traffic conditions, and in a reasonable time.

Considerations of space make it impossible to describe in detail the three machines at present in use, but a brief examination of the latest machine will serve to show 'how the testing conditions have been brought to represent, with a good degree of accuracy, the type of traffic conditions commonly met on our main highways.

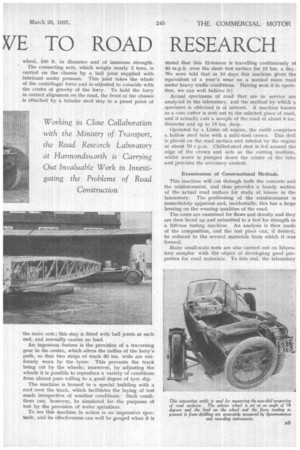

This apparatus has been constructed primarily for the study of surface conditions, such as surface dressing, skidding and impact. It consists of a standard A.E.C. short-wheelbase chassis with the engine replaced by an electric motor. The chassis is loaded to a gross weight of 12 tons and rotates on a circular track which is 10 ft. wide and has a mean diameter of 110 ft.

It is attached to a centre post by a structural steel arm and it operates at speeds up to 40 m.p.h. At this speed, the centrifugal force on the chassis amounts to about 25 tons, and to combat this force the frame has been greatly strengthened by heavy steel plates.

To resist the sideway forces on the centre post, it is bedded in a reinforced concrete pier with concrete radial arms, so that the foundation forms a reinforced concrete

wheel, 100 ft. in diameter and of immense strength.

The connecting arm, which weighs nearly 5 tons, is carried on the chassis by a ball joint supplied with lubricant under pressure. This joint takes the whole of the centrifugal force and is adjusted to coincide with the centre of gravity of the lorry. To hold the lorry in correct alignment on the road, the front of the chassis is attached by a tubular steel stay to a panel point of the main arm ; this stay is fitted with ball joints at each end, and normally carries no load.

An ingenious feature is the provision of a traversing gear in the centre, which alters the radius of the lorry's path, so that two strips of track 30 ins, wide are uniformly worn by the tyres. This prevents the track being cut by the wheels; moreover, by adjusting the wheels it is possible to reproduce a variety of conditions from almost pure rolling to a good degree of tyre slip.

The machine is housed in a special building with a roof over the track, which facilitates the laying of test roads irrespective of weather conditions. Such conditions can, however, be simulated for the purposes of test by the provision of water sprinklers.

To see this machine in action is an impressive spectacle, and its effectiveness can well be gauged when it is stated that this 12-tonner is travelling continuously at 40 m.p.h. over the short test surface for 16 hrs. a day. We were told that in 10 days this machine gives the equivalent of a year's wear on a normal main road under heavy traffic conditions. Having seen it in operation, we can well believe it!

Acilial specimens of road that are in service are analysed in the laboratory, and the method by which a specimen is obtained is of interest. A machine known as a core cutter is sent out to the selected piece of road, and it actually cuts a sample of the road of about 8 ins. diameter and up to 18 ins. deep.

Operated by a Lister oil engine, the outfit comprises a hollow steel tube with a mild-steel crown. This drill is placed on the road surface and rotated by the engine at about 70 r.p.m. Chilled-steel shot is fed around the edge of the crown and acts as the cutting medium, whilst water is pumped down the centre of the tube and provides the necessary coolant.

examination of Constructional Methods.

This machine will cut through both the concrete and the reinforcement, and thus provides a handy section of the actual road surface for study at leisure in the laboratory. The positioning of the reinforcement is immediately apparent and, incidentally, this has a large bearing on the wearing qualities of the road.

The cores are examined for flaws and density and they are then faced up and submitted to a test for strength in a 500-ton testing machine. An analysis is then made of the composition, and the test piece can, if desired, be reduced to the several materials from which it was formed.

Many small-scale tests are also carried out on laboratory samples with the object of developing good properties for road materials. To this end, the laboratory

is fully equipped for producing its own road materials and testing them under a wide variety of conditions.

An extremely interesting outfit is used to measure the non-skid properties of road surfaces and this comprises a motorcycle and sidecar, the wheel of the sidecar being mounted on a separate frame pivoted from the main chassis about a vertical axis, thus forming a castor arrangement.

When testing, the outfit is driven along the road with this wheel fixed at an angle of 18 degrees to the direction of motion and both the normal force tending to prevent it skidding, and the load on the wheel, are measured by dynamometers and recording instruments. The results obtained by this machine are proving of real value and the Ministry of Transport is likely, we understand, to provide a number of similar machines for use in all parts of the country.

It is impossible, within the scope of this article, to survey other than briefly the work of the laboratory, and the many experiments in progress embrace a field that is so extensive as to merit the close consideration of all highway engineers. A recent brief visit to Harmondsworth impressed deeply upon usthe fact that our road engineers are striving to provide highways that will meet fully the needs of all road users. It remains for Parliament to see that we get them.