The Purchase Department.

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Where to Buy your Supplies.

You Can Get It At " 1-t.S." (Manchester).The grease you require is made by the Vacuum Oil Co., Ltd., Caxton House, Westminster, S.W.

Brake and Clutch Linings.

. The impregnated woven fabric form of brake and clutch lining is now finding much favour with the chassis builder, and many manufacturers arc using one or another of the different makes now on the market iii place of the older form of cast-iron faend shoes. The Autobestos Syndicate, 3, Leieester Street. Londen, W.C., is marketing a brake and clutch lining

constructed of pure asbestos yarn interwoven with fine brass wire. The fabric is impregnated with a special compound, which renders the material impervious to water, oil, dust, or heat.

By using a fabric of this description the chattering and squeaking often set up by the ordinary metal-tometal brake is prevented. A great factor with Autobestos is the noiseless. quick, yet smooth braking effect obtained, which has an undoubted saving in the matter of both tires and transmission gear. The material will always remain pliable and does not crack or disintegrate.

Autobestos is turned out in strip and sheet form, and may be cut into any desired shape, and the fact that trimly leading commercial-vehicle manufacturers in this country are now using this speciality is proof that it is of a high-grade quality.

Catalogues Received.

A copy of the latest. catalogue issued by Hunts, Ltd., 117, Long Acre, London, W.C., is to hand. This comprehensive book contains 813 pages, and great care has been exercised in its compilation. The catalogue contains illustrations of accessories which should prove useful to both automobile and general engi veers.

We have received from the Parsons Motor Co., Ltd., Town Quay Works, Southampton, a copy of its new catalogue dealing with stationary and marine engines.

This is carefully. prepared and includes numerous illustrations of Parsons specialities. It will interest our readers to know that this maker builds engines particularly suitable for portable electric-welding sets.

Self-lubricating Shackle-bolts.

An important point which the would-be purchaser of an industrial machine should take into consideration is that means be provided for the adequate supply ol itibricant to all pin-joints throu0out the chassis in addition to the main system of lubrication.

Countersunk holes drilled into bettring-braekets to receive the lubricant flre not sufficient, and moreover soon get clogged with dirt. Large-sized grease and dust-caps should be a feature of the chassis, and they should be so located as not to escape the eye of the driver during the ordinary run of his duties.

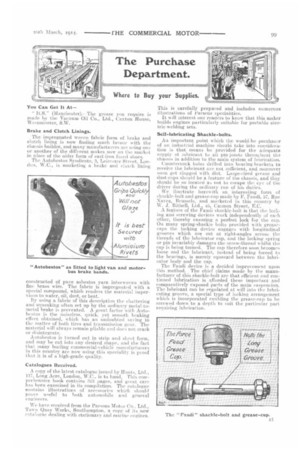

We iliustrate herewith an interesting form of sliackle-bolt and grease-cup made by F. Faudi, 57, Rue NONCZ, Brussels, and marketed in this country by W. J. Bithell, Ltd., 46, Cannon Street, E.C. A feature of the Faudi shackle-bolt is that the locking and screwing devices work independently of each other, thereby ensuring a perfect lock for the cap. On many spring-shackle bolt si provided with greaseeaps the locking device engages with longitudinal grooves which are cut at right-angles across, the threads of the lubricator cap, and the locking spring or pin invariably damages the screw-thread whilst the cap is being turned. The cap therefore soon becomes loose and the lubricant, instead of being forced to the bearings, is merely squeezed between the lubricator body and the cap.

The Faudi device is a decided improvement upon this method. The chief claims made by the manufacturer of this shackle-bolt are that efficient, and continued lubrication is afforded these important and comparatively exposed parts of the main suspension. The lubricant can be regulated at will into the lubricating groove, a special type of iocking arrangement which is incorporated enabling the grease-cap to be screwed down to a depth to suit the particular part requiring lubrication.