Brakes, 6

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

THE WATER which accumulates in the air reservoirs (CMJune 12) in an air braking system may freeze in very cold weather. This will seriously interfere with braking efficiency. Alcohol bottles are used to prevent this occurring.

Incoming air bubbles through the alcohol contained in the bottles and some of the alcohol, in vapour form, is carried along with the air stream to the compressor and consequently into the braking system.

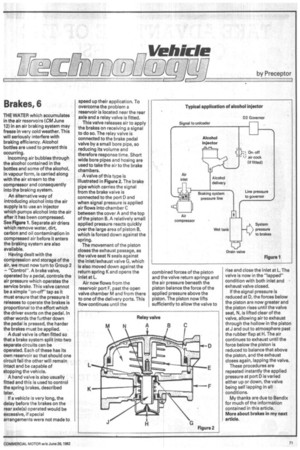

An alternative way of introducing alcohol into the air supply is to use an injector which pumps alcohol into the air after it has been compressed. See Figure 1. Separate air driers which remove water, dirt, carbon and oil contamination in compressed air before it enters the braking system are also available.

Having dealt with the compression and storage of the air, we must now turn to Group 2 — "Control". A brake valve, operated by a pedal, controls the air pressure which operates the service brake. This valve cannot be a simple "on-off" tap as it must ensure that the pressure it releases to operate the brakes is proportional to the effort which the driver exerts on the pedal. In other words the further down the pedal is pressed, the harder the brakes must be applied. A dual valve is often fitted so that a brake system split into two separate circuits can be operated. Each of these has its own reservoir so that should one circuit fail the other will remain intact and be capable of stopping the vehicle.

A hand valve is also usually fitted and this is used to control the spring brakes, described later.

If a vehicle is very long, the delay before the brakes on the rear axle(s) operated would be excessive, if special arrangements were not made to speed up their application. To overcome the problem a reservoir is located near the rear axle and a relay valve is fitted.

This valve releases air to apply the brakes on receiving a signal to do so. The relay valve is connected to the brake pedal valve by a small bore pipe, so reducing its volume and therefore response time. Short wide bore pipes and hosing are used to take the air to the brake chambers.

A valve of this type is illustrated in Figure 2. The brake pipe which carries the signal from the brake valve is connected to the port D and when signal pressure is applied air flows into chamber C between the cover A and the top of the piston B. A relatively small applied pressure reacts quickly over the large area of piston B, which is forced down against the spring.

The movement of the piston closes the exhaust passage, as the valve seat N seals against the inlet/exhaust valve G. which is also moved down against the return spring K and opens the inlet at L.

Air now flows from the reservoir port F, past the open valve chamber M and from there to one of the delivery ports. This flow continues until the combined forces of the piston and the valve return springs and the air pressure beneath the piston balance the force of the applied pressure above the piston. The piston now lifts sufficiently to allow the valve to rise and close the inlet at L. The valve is now in the "lapped" condition with both inlet and exhaust valve closed.

If the signal pressure is reduced at D, the forces below the piston are now greater and the piston rises until the valve seat, N, is lifted clear of the valve, allowing air to exhaust through the hollow in the piston at J and out to atmosphere past the rubber flap at H. The air continues to exhaust until the force below the piston is reduced to balance that above the piston, and the exhaust closes again, lapping the valve.

These procedures are repeated instantly the applied pressure at port D is varied either up or down, the valve being self lapping in all conditions.

My thanks are due to Bendix for much of the information contained in this article. More about brakes in my next article.