A NEW CHALLENGE TO DIESEL

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Teca.lemit low-cost petrol injection gives promise of remarkable fuel economy.

TH E announcement by Tecalemit (Developments) Ltd.. Plymouth, of a new low-cost petrol injection system suitable for private-car and commercial-vehicle power units of 50 b.h.p. to 350 b.h.p. should be of special interest to the many commercialvehicle operators who would prefer to run petrol-engined vehicles given that the power units' fuel consumption could be substantially improved. Petrol injection increases the power output obtainable as well as reducing consumption, and, of particular significance to commercial-vehicle users, consumption can be further improved by de-rating the engine to the output of the carburetted version. Tests by Tecalemir technicians have shown that the use of petrol injection can reduce specific fuel consumption by 25 per cent if output is not uprated and that this gain is applicable to the entire load-speed range of the unit. The equipment is known as the TecalemitJackson system and has been applied to engines of 1.5 litres up to 4-7 litres without modification to the engine apart from the use of a special manifold.

An overall fuel-consumption gain well in excess of 25 per cent could undoubtedly be obtained in the case of a " dc-rated" engine if, appropriate modifications were made to the valve timing and if advantage were taken of the fact that the compression ratio of the unit can normally be increased by at least one ratio if petrol injection is employed. The total gain in consumption could well be. betterthan 33 per cent, the improved low-speed torque offered by petrol injection also being of value on the road. A cold-start device is fitted, but its use can normally be discontinued as soon as the engine is running and the effect on consumption of frequent cold starts is minimized. In a typical case, the operator of a vehicle powered by a lowcompression engine would be given the choice of running on commercial fuel with an increase in compression ratio of one ratio, or of running on a high-octane fuel with a compression-ratio increase of two or more ratios.

In Tecalemit tests of a. l.5-litre highperformance engine fitted with the system. maximum output has been increased by 15.6 per cent whilst the full-toad specific fuel consumption curve shows a gain of nearly. 20 per cent at higher speeds. Torque output is improved at speeds above 40 per cent of maximum speed with variations between 8,5 per cent and 15-5 per cent.

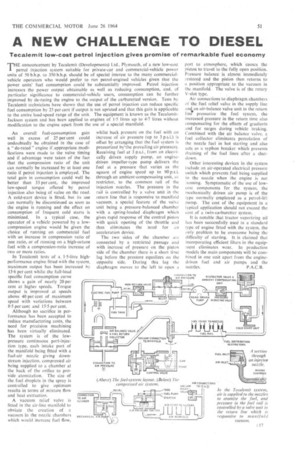

Although no sacrifice in performance has been accepted to reduce manufacturing coSts, the need for precision machining has been virtually eliminated. The system is of the lowpressure continuous port-injection type, each intake port of the manifold being fitted with a fuel-air nozzle giving downstream injection, compressed air being supplied to a chamber at the back of the orifice to provide atomization. The size of the fuel droplets in the spray is controlled to give optimum results in terms of mixture flow and heat extraction'.

A vacuum relief valve is fitted in the air-line manifold to obviate the creation of a vacuum in the nozzle chambers which would increase fuel flow, whilst back pressure on the fuel with an increase of air pressure (up to 3 p.s,i,) is offset by arranging that the fuel system is pressurized by'the prevailing air presssure. Receiving fuel at 3 psi., from an electrically driven supply pump, an enginedriven impeller-type pump delivers the fuel at a pressure that varies as the square of engine speed up to 90 p,s.i. through an ambient-compensating unit, or restrictor, to the common rail of the injection nozzles. The pressure in the rail is controlled by a valve unit in the return line that is responsive to manifold vacuum, a special feature of the valve unit being a pressure-balanced chamber with a spring-loaded diaphragm which gives rapid response of the control piston with quick opening of the throttle and thus eliminates the need for an acceleration device.

The two sides of the chamber are connected by a restricted passage and with increase of pressure on the piston side of the chamber there is a short time lag before the pressure equalizes on the opposite side. During this lag the diaphragm moves to the left to open a

port to atmosphere, which causes the piston to travel to the fully open positiOn. Pressure balance is almost immediately restored and the piston then returns to a position appropriate to the vacuum in the manifold. The valve is of the rotary V-slot type.

Air connections to diaphragm chambers of the fuel relief valve in the supply line anqpan air-balance Valve unit in the return line pressurize the fuel system, the increased pressure in the return time also compensating for the effects of gradients and for surges during vehicle braking. Combined with the air balance valve, a fuel collector eliminates percolation of the nozzle fuel in hot starting and also acts as a syphon breaker which prevents draining of the fuel lines after a shutdown.

Other interesting devices in the system include an air-operated electrical pressure switch which prevents fuel being supplied to the nozzle when the engine is not running. Symptomatic of the use of lowcost components for the system, the mechanically driven air pump is of the type normally' employed as a petrol-lift pump, 'The cost -of the equipment in a typical application should not exceed the cost of a twin-carburetter system.

It is notable that tractor vaporizing oil has been successfully used in a standard type of engine fitted with the system, the only problem to be overcome being the difficulty of starting. It. is claimed that incorporating efficient filters in the equipment eliminates wear. in production models the main components will be combined in one unit apart from the enginedriven fuel and air pumps and the

nozzles. P.A.C.B.