Latest H.S.G Producer Gas Conversions

Page 28

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

'WE announced in our issue dated May 29 that fife H.S.G. producergas apparatus was now to be made and marketed under the control of Wylie Ilarris and Co., trewery Road, London, N.7, and that a newly formed firm, Messrs. High Speed Gas, would produce the plant at the works at Treforest, South Wales. Already, under the new regime, a number of such outfits has been completed and delivered, and the present position is that the works is operating at full pressure fulfilling orders in hand.

The first job to leave the factory since the change in control -was a Leyland Cub 4-tonner, equipped v4fh H.S.G. plant, for Davenport's " C-B " Ltd., a Birmingham brewery concern. It represented the sixth conversion executed by the H.S.G. concern for this operator.

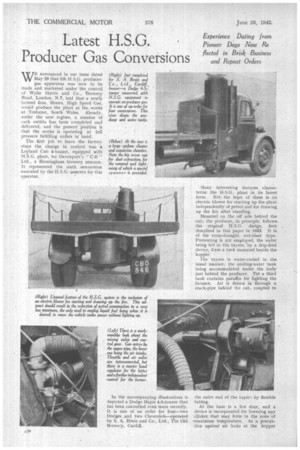

In the accompanying illustrations is depicted a Dodge Major 4-5-tonner that has been converted even more recently. It is one of an order for four—two Dodges and two Chevrolets—operated by S. A. Brain and Co:, Ltd., The Old Brewery, Cardiff.

Many interesting features characterize the H.S.G. plant in its latest form. Not, the least of these is an electric blower for starting up the plant independently of petrol and for drawing up the fire after standing.

Mounted on the off side behind the cab, the producer, in principle, follows-the original II.S.G. design, first described in this paper in 1933. It is of the cross-draught, wet-blast type. Preheating is not employed, the water being fed to the tuyere, by a drip-feed device, frpm a tank mounted beside the hopper.

The tuyere is water-cooled in the *usual manner, the cooling-water tank being accommodated under the body just behind the producer. Yet a third tank contains paraffin for lighting the furnace. Air is drawn in through a stack-pipe behind the cab, coupled to

the outer end of the tuyera by flexible tubing.

At the base is a fire door, and a device is incorporated for lowering any clinker that may form in the zone of -maximum temperature. As a precaution against air leaks at the hopper cover, this fitment, a notably sturdy pressing, is provided, on its inner fd.ce, with guides which ensure that it is truly centralized when replaced after replenishing the producer with fuel: In the case of this cover and of the fire door, well-made. and adequately strong securing devices are employed.

From the gas off-take a pipe leads to a big cyclone filter at the rear. For extracting the dust from this, a large screw cap is fitted to the •centre of the bb.se, which is the shape of a shallow inverted cone. Sockets are formed in the periphery of the cap to receive pegs on a special C spanner, provided as an item of the equipment. „.

Gas flows from this filter to two sisal cleaners, accessibly positioned under the body platform on the near side just ahead of the road wheel. Strong interchangeable pressed-steel covers give ready access to their interiors, whilst spiders, with tightening centre screws, hold the filtering medium under the necessary pressure. , In its now fairly thoroughly cleansed state, the gas arrives at an oil-bath filter, where the finest particles are retained, and a certain amount of fluid is picked up and carried on, for uppercylinder lubrication.

Gas enters the mixing valve by the upper 'pipe, depicted in an accompanying illustration, and air by the lower one, which is connected to the blower. The air valve and the throttle are interconnected, whilst hand controls regulate respectively the proportion of air to gas and the setting of the throttle for conditions of running normally, running on petrol and starting up.

The petrol carburetter is a small unit designed to serve only for starting up or shunting the vehicle, and is provided with a control which puts it in or out of action.

The v-hole assembly is essentially workmanlike. Piping, bends, joints, controls, etc., are all well designed and constructed and are dearly the outcome of long experience and a determination on the part of the manufacturers to adhere rigidly only to sound engineering practices.

We understand that enough Progasite fuel can be accommodated in the hopper of this plant for 350 miles, and that the consumption rate is

• approximately 4 lb. per mile.