A POWER UNIT FOR HIGH-SPEED VEHICLES.

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

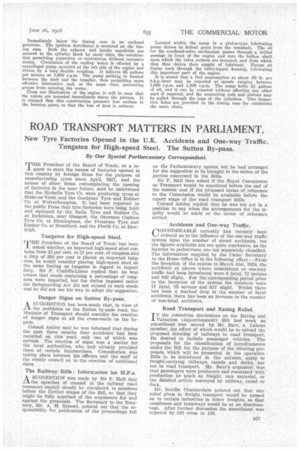

• Details of a New Continental Engine with Six Cylinders and Rocker-operated Overhead Valves.

ONE of the best-known makes of proprietary engine, and one of which examples are utilized to a considerable extent in this country, is the Continental.

For some time past the Continental Motors Corporation has been engaged in the development of a series of sixcylindered engines with _. overhead valves, especially designed for passenger vehicles and fast lorries. This series is known as the Model Ii, and is now iu production at the Detroit and Muskegon plants.

The outstanding features are, of course, the valve construction, to which we have already referred, and the smooth running afforded by the, comparatively, short stroke. For instance, the model 20R has a bore of 41, ins. and a stroke of 4i ins., -giving a piston displacement of 381 cu. ins. This engine develops 87 b.h.p. at 2,400 r.p.m. The maximum torque is provided at 700 r.p.m. and is 242 lb.-ft.

A very substantial crankshaft runs in seven main bearings, each having a cap secured by four bolts. An unusual feature is the employment of nickel iron for the cylinder block, which, incidentally; is cast in one with the crankcase. To prevent undue vibration and weaving the crankcase is heavily ribbed, whilst the camshaft and flywheel are balanced statically and dynamically. Chilled east-iron wearing surfaces are provided for the tubular steel pushrods, and they operate the valve rockers through the medium of adjustable pins having hemispherical heads.. Over the end of each valve stem is slipped a thimble with • a cupped head, into which fits a ball-ended pin mounted on the other end of the rocker. All moving parts of this valve mechanism are supplied with oil under pressure, whilst the driving chain at the front end of the engine is kept flooded.

The main bearings have a diameter of 21 ins. They are interchangeable, and the bearing load never exceeds 800 lb. per sq. in.

Silicon-chromium steel is used for the exhaust valves and chrome-nickel steel for the inlet valves; both are provided with double springs.

The camshaft and crankshaft chain sprockets are close r26 together, there being only six links between them, so that wear of the chain does not appreciably affect the valve timing. The sprocket bearings are, of course, lubricated under pressure. A feature which will appeal to many users is that the fan is positively driven by the timing chain, whilst each auxiliary has its individual drive from the main housing and can be removed without disturbing any other unit.

Au air compressor having a capacity of either. 3 cu. ft. per minute or 6 Cu. ft. per minute can be installed if required, in which case it is driven from an eccentric on the front end of the crankshaft. Immediately below the timing case is an enclosed governor. The ignition distributor is mounted on the timing case. Both the exhaust and intake manifolds are secured to the cylinder block by stout clips, the construetion permitting expansion or contraction without excessive strain. Circulation" of the cooling water is effected by a centrifugal pump mounted at the left side of the engine and driven by a long flexible coupling. It delivers 05 kallans per minute at 1,600' r.p.m. The pump packing is located between the dash and the impeller, thus permitting more effective lubrication and, at the same time, preventing grease from entering the water.

From our illustration of the engine it will be seen that the valves are mounted immediately above the pistons. It is claimed that this construction presents less surface to the burning gases, so that the loss of heat is reduced. Located within the sump is a pinion-type lubricating pump driven by helical gears from the camshaft. The oil for the overhead-valve mechanism passes through a drilled pasiage in front of the engine and into the hollow shaft upon which the valve rockers are mounted, and from which they. thus derive their supply of lubricant. ExeeSs oil drains back through the valve-tappet housing, lubricating this important part of the engine.

It is stated that a fuel consumption at about .66 lb. per h.h.p.-hour may be expected at speeds ranging between 1,000 r.p.m. and 1,800 r.p.m. The sump holds 2-i gallons of oil, and it can be removed without affecting any other part if required, and the connecting rods and pistons may be pulled through the tops of the cylinders. Two inspection holes are provided in the timing case for examining the main chain. .