U.S. HAULAGE PERSPECTIVE

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon,

A.M.I.Mech.E.

CLOSE on urn, commercial vehicles were registered in the U.S.A. during 1956—over 45 per cent. 'or the total number of trucks in the world—compared with the 1.17m. operating in Great Britain at that time. Over lm. of these trucks are more than 15 years old, but one of the most surprising facts is that fewer than 100,000 oil-engined vehicles are in use whereas we have over 180,000.

There are 650,000 trailers of 5-ton capacity and above in use in America, which gives a good clue to the makeup of the average long-distance haulage vehicle—a petrol-engined articulated unit. It is known, in fact, that 32 per cent. of the mileage covered by commercial vehicles each year is with trailer and semi-trailer units, representing 75 per cent. of the annual tonmileage in the country.

12,000m. Tons by Road

Road vehicles move 48 per cent. of all tinned fruits and vegetables, 68 per cent, of all frozen foods, 55 per cent. of fresh fruits and vegetables, 80 per cent, of all livestock, 85 per cent. of all new cars, and 77 per cent. of all sand and gravel. It has been estimated that 12,000m. tons of goods were moved last year by road over a total •mileage of 115,000rn., and that more than 6m. people are employed as haulage drivers.

This is big business in the truest sense of the word, and one which acts as a vital stimulus to commercialvehicle manufacturers. Hauliers are already experiencing some drastic changes in the design of present-day vehicles, and these are likely to become even more pronounced within the next 10 years or so. Advanced experiments are being conducted with free-piston turbine and gas-turbine power units, whilst automatic transmissions and air suspension systems are already available on certain makes.

A further significant change, which is gathering momentum, is the trend towards the use of forwardcontrol " vehicles. As in Europe, this is principally because of State restrictions limiting overall lengths and individual axle loadings. Not, however, that the axle loadings are so important these days, because in the majority of cases it is bulk that is the average haulier's chief enemy.

It is obvious that most American domestic commodities are steadily becoming lighter and occasionally bulkier. The use of new materials, such as plastics and laminated timbers, is making this possible, and therefore a 15-ton load will possibly occupy 50 per cent. more space than it did, say, 10 years ago.

This fact, combined with State resttictions, has made the Use of forward-control vehicles, particularly prime movers, imperative. Even those operators running in such western States as Arizotia, California, Idaho? Montana, New Mexico and Washington—where in some cases overall lengths of about 65 ft. are perrnittedmust restrict their vehicle length to 50' ft., or 45 ft. if they intend operating into more easterly parts of the country.

Why Forward Control Was Unpopular

It is easy to ask, as I did, why the forward-control vehicle has not previously achieved the same degree of popularity as it has in Great Britain. One of the main reasons was the lack of engine accessibility. Subsidiary reasons were the importance of a comfortable cab for the driver and crew, and the relatively large amount of "road room" available in a vast country such as the United States.

This opposition to forward-control designs has been overcome by the use of tilting cabs, which were introduced by the White Motor Co.. soon after the war and have been successively taken up by the Diamond T Motor Car. Co., International Harvester Co., and, about six months ago, by the Ford Motor Co.

The boot can now, in fact, be said to, be on the other foot, because the country that has been mainly responsible for the pioneering of forward-control vehicles—

Great Britain is now sadly behind the United States in providing good engine accessibility. Progress in this direction in Britain has been almost nil in the past 30 years.

Sales of the Ford tilting cab models have already, far exceeded all expectations since their introduction in February, and operators are claiming that well over 50 per cent. of labour costs and workshop delays are saved • because of the greatly improved engine accessibility available. A further consideration is that mechanics, because they are able to reach the engine properly, are being more conscientious about their work.

An extremely high percentage of the commercial ve:iicles in use in America have petrol engines, as the figures quoted at the beginning of this article show.

There are many reasons for this. In the case of light and medium-capacity vehicles the greater initial pur chase price and subsequent higher maintenance costs have turned most hauliers away from the idea of using oil engines. This tendency has been accentuated by the steadily rising cost of ail fuel in America, which is now little less than that of petrol.

Hence the economy of oil-engine operation has been ,decreasing. Furthermore, fully qualified oil-engine ser vice stations are still few outside the main cities, which these factors combine with the weight and bulk penalties of the oil engine to make the high-efficiency petrol unit by far the most popular for even long-distance haulage.

In Britain, we have become used to oil engines which have a high power-to-weight ratio, but in America an oil engine will weigh up to three times as much as an equivalentpowered petrol unit. It has been proved that lighter engines cannot stand up to continuous high-speed running at gross vehicle weights of up to (in certain States) 30 tons.

The speed required of modern heavy-haulage vehicles is an important factor, and such machines must be able to maintain average speeds of 50 m.p.h. or so over long distances. For this sort of work a high horse-power rating is essential.

When not on the open road, these vehicles are obliged to keep up with the general pace of city traffic and, for this, lively engines with high torque outputs are required. The obvious outcome, therefore, has been the development of compact, reasonably lightweight high-powered petrol engines which, although not as economical as compression-ignition units, are initially cheaper, easier to maintain, and can stand up to continuous highspeed operation, with the further advantage that they can keep pace with fast-moving city traffic.

A typical American 54-litre V8 petrol engine will develop at least 210 b.h.p. at ,around 4,000 r.p.m., and have a torque output of 325 lb.-ft. or more at 2,500 r.p.m. By comparison, a large oil engine of, say, 11 litres, would develop only 170 b.h.p., or 205 b.h.p.. if turbo-charged. The space and weightsaving properties of the American petrol engine are obvious, therefore, but what of fuel cost?

It was estimated by the American Trucking Association that in 1954 fuel represented only 6.7 per cent. of the total operating costs of haulage, compared with the 57 per cent. accounted for by labour charges. This, then, is the key to why so much attention has been paid to the development of the petrol unit, whilst oil engines remain comparatively inefficient in terms of power-toweight ratios.

Speed of turn-round and speed on the road, together with simplified maintenance and shorter repair delays, are the only sure ways of keeping the labour charges low, and as long as this can be done fuel costs are relatively unimportant. It is obvious that the continued trend for the majority of haulage vehicles will be towards the development of high-speed short-stroke petrol engines, this design having been shown to give longer life under high-speed conditions. A particular advantage of this type of unit is the relatively low torque output at low engine speed.

• This anomaly is explained by the fact that it is this characteristic which makes it essential for drivers to keep the engine speed high to get maximum null, which in turn cuts down engine failures that can come about through " lugging the unit, and causing high individual crank-pin loadings.

Automatic Transmissions

Another way of preventing this tendency towards drivers lugging" their engines is to adopt the torque converter or automatic-gearbox transmissions. One of the most successful automatic transmissions so far applied to haulage vehicles has been the G.M.C. HydraMatic, with its doubled-up version—the twin HydraMatic—as used on the heavier machines. In May of this year, Ford introduced a six-speed torque-converter transmission, but no operating experience has yet been gained.

There is a wide divergence of opinion as to the effect on overall operating costs of such transmissions, although nobody can deny that, so far as the reduction of driving fatigue is concerned, they are invaluable.

Generally, however, with the G.M.C. box the fuelconsumption rate is increased by the relatively low transmission efficiency associated with the fluid coupling and epicyclic gear trains, compared with that of conventional transmission layouts. One fleet manager with whom I spoke, although disappointed with the Hydra-Matic transmission, was fully prepared experimentally to adopt torque converters. He thought that they would give better results than straight gearboxes, particularly as it would be impossible for the driver to damage the engine, transmission or axle.

He believed that this applied especially with vehicles engaged on local delivery work and there was the further advantage that a two-speed axle could be dispensed with, as sufficient torque would be given by the converter.

Reducing Driving Strain

It would appear, however, that most operators arc in favour of the idea of an automatic transmission of some sort, not only to reduce driving strain, concentration and skill. but also to cut repair costs. The reduced fuel economy would, after all, be a mere drop in the ocean compared with the overall operating costs.

Already some operators have received entirely satisfactory results with automatic gearboxes, but these were mostly in fleets where a comprehensive driver and mechanic training programme had been instituted. Everywhere I found great emphasis laid on the need for correct and regular .maintenance of these transmissions, although this did not aptly to such an extent to torque converters, which generally require little adjustment.

A further advantage of the torque converter is that its role as an infinitely _variable gearbox ensures that the power at the back -axle is directly suited to varying conditions of operatiOn, hence the use of torque converters to obtain good acceleration on city buses and good hill climbing and cross-country power on dumpers, tippers and the like.

It is the combination of torque converter and highefficiency petrol engine which is, at the moment, causing most concern to oil-engine manufacturers, although in the background there looms the added " menace " of the c8 gas turbine and the free-piston engines. Indeed, only by increasing the power-to-weight ratios of current American oil engines and matching them with torque converters can the almost inevitable adoption of one or other of these two new units be staved off.

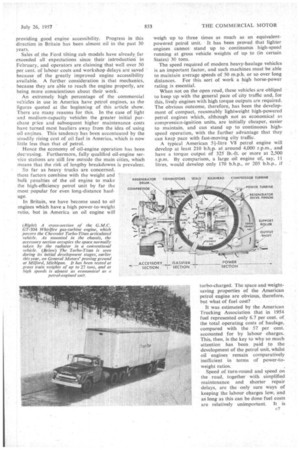

Experimental progress with free-piston and gas turbine engines is already showing desirable results. For example, the Chevrolet Turbo-Titan articulated Unit. which is being tested at up to 27 tons gross, has shown substantial improvements in acceleration " and hillclimbing ability, whilst the fuel-consumption rate at speeds above 50 m.p.h. is little higher than that of an equivalent pet rol-engined vehicle.

In fact, the projected General Motors gas turbine engine, which is five or six years distant, is confidently expected to have a specific fuel consumption on a par with that of current American oil engines. Ford also have fitted a gas turbine unit intopne of the new tiltingcab trucks.

Virtues of New Engines

Advantages of both gas turbine and free-piston engines are numerous, but the piincipal ones are that full torque output is at a maximum value at stall speed; complex transmission systems are unnecessary; liquid cooling systems can be dispensed with; the units are lighter and more compact; starting is relatively easy, and oil pollution almost nil.

Subject to the expected development of an economical regenerative-type gas turbine and the subsequent massproduction of such a unit, it is possible. that this form of power will offer distinct advantages in respect of overall operating economy. I think that the free-piston unit is more likely to be adapted in goods vehicles before the gas turbine, mainly because already specified fuel-consumption figures, comparable with those of current oil engines, are being obtained.

The success of these new power units will, of course, be decided by the operator, who, like his British contemporaries, is wary of new devices. This factor explains why the adoption of fully automatic transmission, particularly on long-distance vehicles, has not been fast, despite the proved advantages in speeding up schedules —an important consideration when drivers can earn up to S125 (f:45) a week.

The last war, however, did much to soften this inherent sales resistance, as people engaged actively in the

war were able to see for thernselve4.how these new " gimmicks " worked.

So far as automatic transmissions are concerned, particularly on long-distance machines, there is little question of extra initial cost, as such vehicles are frequently equipped with five-speed main gearboxes, three-speed auxiliary boxes and two-speed axles, which could easily be replaced by one seven-speed automatic unit for about , the same price.

The other radical change most likely to affect operators in the immediate future will be the more general adoption of air suspension systems for rigid and articulated units. A start has already been made with the General Motors option of air suspension on a number of their standard prime movers. This suspension system has been evolved as a result of the success of a similar layout on G.M. buses and coaches, and although embodying the same general principle is different in layout.

Front axles of air-suspended chassis are tubular. divided into two compartments and used as air storage space for the dual bellows units which are located at each end. A single levelling valve on the right of the frame controls the pressure inside these bellows, which varies from 35 p.s.i. when the vehicle is empty to 75 p.s.i. when fully laden. The axle is located by longitudinal radius arms and a transverse Panhard rod.

The rear axle is carried on two square-section radius rods (similar to the A.C.V. Bridgemaster layout) which act as air reservoirs and carry single bellows at their rear ends. Levelling valves are used at each of these radius rods to prevent roll, and to compensate for unevenly loaded payloads and badly cambered roads.

Although the obvious advantage of such a suspension system, which is also being adopted on semi-trailers, is the smooth ride given perhaps the greatest benefit to operators is the abolition of spring maintenance and repairs. Moreover, the risk of breakdown of chassis or running units when travelling unladen is substantially reduced, because of the vastly improved insulation against road shocks. It seems doubtful that any major development in the field of braking is likely to take place in the course of the next five years or so, other than the possibility of the adoption of metallic or ceramic-metallic fadeand heat-resisting brake facings. Fade is the main problem to be overcome, and although disc brakes are not even at the development stage, downhill retardation devices, such as electric transmission brakes and gearboxes with built-in retarders, are being put on the market.

With the high speeds already practised by goods vehicles on the American highways and with the still higher speeds likely to become commonplace when the new 42,000-mile expressway programme has been completed, the question of braking is all-important, and it is obvious that serious thought is already being given to it. Continued detail improvements are being made, such as the general adoption of tubeless tyres, which not only save weight but have also been shown to give higher mileages because they run cooler. Some manufacturers offer cab "safety packages," containing such items as padded sun visors and instrument panels, and even seat belts, with the object of reducing injuries to drivers.