Balancing act

Page 128

If you've noticed an error in this article please click here to report it so we can fix it.

• While most people are willing to balance the tyres on their cars, how often do truck tyres get balanced? Yet, out-of-balance truck tyres are responsible for uneven tyre wear and reduced life, driver fatigue, accelerated wheel-bearing wear and, ultimately, total bearing collapse.

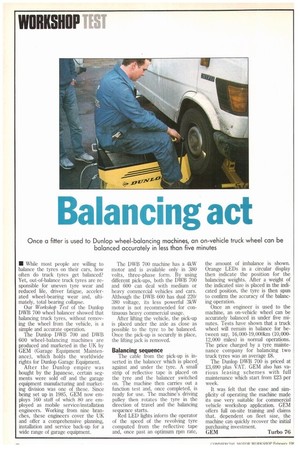

Our Workshop Test of the Dunlop DWB 700 wheel balancer showed that balancing truck tyres, without removing the wheel from the vehicle, is a simple and accurate operation.

The Dunlop DWB 700 and DWB 600 wheel-balancing machines are produced and marketed in the UK by GEM (Garage Equipment Maintenance), which holds the worldwide rights for Dunlop Garage Equipment.

After the Dunlop empire was bought by the Japanese, certain segments were sold off and the garage equipment manufacturing and marketing division was one of these. Since being set up in 1985, GEM now employs 160 staff of which 80 are employed as mobile service/installation engineers. Working from nine branches, these engineers cover the UK and offer a comprehensive planning, installation and service back-up for a wide range of garage equipment. The DWB 700 machine has a 4kW motor and is available only in 380 volts, three-phase form. By using different pick-ups, both the DWB 700 and 600 can deal with medium or heavy commercial vehicles and cars. Although the DWB 600 has dual 220/ 380 voltage, its less powerful 3kW motor is not recommended for continuous heavy commercial usage.

After lifting the vehicle, the pick-up is placed under the axle as close as possible to the tyre to be balanced. Once the pick-up is securely in place, the lifting jack is removed.

Balancing sequence

The cable from the pick-up is inserted in the balancer which is placed, against and under the tyre. A small strip of reflective tape is placed on the tyre and the balancer switched on. The machine then carries out a function test and, once completed, is ready for use. The machine's driving pulley then rotates the tyre in the direction of travel and the balancing sequence starts. Red LED lights inform the operator of the speed of the revolving tyre computed from the reflective tape and, once past an optimum rpm rate, the amount of imbalance is shown. Orange LEDs in a circular display then indicate the position for the balancing weights. After a weight of the indicated size is placed in the indicated position, the tyre is then spun to confirm the accuracy of the balancing operation.

Once an engineer is used to the machine, an on-vehicle wheel can be accurately balanced in under five minutes. Tests have shown that a truck wheel will remain in balance for between say, 16,000-19,000km (10,00012,000 miles) in normal operations. The price charged by a tyre maintenance company for balancing two truck tyres was an average 28.

The Dunlop DWB 700 is priced at 23,690 plus VAT. GEM also has various leasing schemes with full maintenance which start from 223 per week.

It was felt that the ease and simplicity of operating the machine made its use very suitable for commercial vehicle workshop application. GEM offers full on-site training and claims that. dependent on fleet size, the machine can quickly recover the initial purchasing investment.

GEM Turbo 76