Keeping tabs

Page 104

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

safety

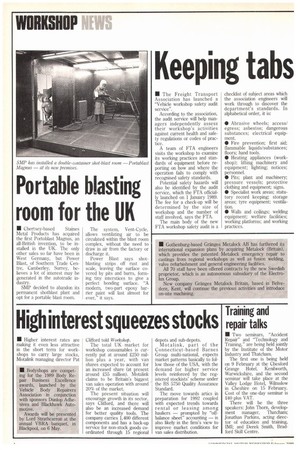

• The Freight Transport Association has launched a "Vehicle workshop safety audit service".

According to the association, the audit service will help managers independently assess their workshop's activities against current health and safety regulations or codes of practice.

A team of PTA engineers visits the workshop to examine its working practices and standards of equipment before reporting on how and where the operation fails to comply with recognised safety standards.

Potential safety hazards will also be identified by the audit service, which the PTA officially launched on 1 January 1989. The fee for a check-up will be determined by the size of workshop and the number of staff involved, says the FTA.

The main body of the new ETA workshop safety audit is a checklist of subject areas which the association engineers will work through to discover the department's standards. In alphabetical order, it is: • Abrasive wheels; access/ egress; asbestos; dangerous substances; electrical equipment.

• Fire prevention; first aid; flammable liquids/substances; floors; hand tools.

• Heating appliances (workshop); lifting machinery and equipment; lighting; notices; personnel.

• Pits; plant and machinery; pressure vessels; protective clothing and equipment; signs.

• Specialist work areas; statutory record keeping; storage areas; tyre equipment; ventilation.

• Walls and ceilings; welding equipment; welfare facilities; working platforms; and working practices.