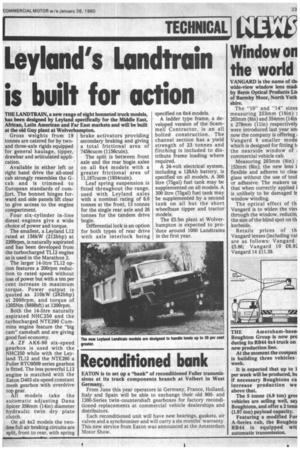

Leyland's Landtrain is built for action

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

THE LANDTRAIN, a new range of eight bonneted truck models, has been designed by Leyland specifically for the Middle East, African, Latin American and Far East markets and will be built at the old Guy plant at Wolverhampton.

Gross weights from 19 tonnes are catered for by twoand three-axle rigids equipped for general haulage, tipper, drawbar and articulated application.

Available in either left or right hand drive the all-steel cab strongly resembles the Gcab and is trimmed to European standards of comfort. The bonnet hinges forward and side panels lift clear to give access to the engine compartment.

Four six-cylinder in-line diesel engines give a wide choice of power and torque.

The smallest, a Leyland L12 rated at 158kW (212bhp) at 2200rpm, is naturally aspirated and has been developed from the turbocharged TL12 engine as is used in the Marathon 2.

The larger 14-litre TL12 option features a 200rpm reduction to rated speed without loss of power but with a ten per cent increase in maximum torque. Power output is quoted as 210kW (282bhp) at 2000rpm, and torque of 1205Nm (8891bft) at 1200rpm.

Both the 14-litre naturally aspirated NHC250 and the turbocharged NTE290 Cummins engine feature the "big cam" camshaft and are giving good fuel economy.

A ZF AK6-90 six-speed gearbox is used with the NHC250 while with the Leyland TL12 and the NTE290 a Fuller RT09509 series gearbox is fitted. The less powerful L12 engine is matched with the Eaton D403 six-speed constant mesh gearbox with overdrive top gear.

All models take the automatic adjusting Dana Spicer 356mm (14in) diameter hydraulic twin dry plate clutch.

On all 4x2 models the twoline full air braking circuits are split, front to rear, with spring brake activators providing secondary braking and giving a total frictional area of 7458cucm (1156cuin).

The split is between front axle and the rear bogie axles on all 6x4 models with a greater frictional area of 11,187cucm (1934cuin).

Leaf spring suspension is fitted thrOughout the range, used with Leyland axles with a nominal rating of 6.6 tonnes at the front, 13 tonnes for the single rear axle and 26 tonnes for the tandem drive bogie.

Differential lock is an option for both types of rear drive with axle interlock being specified on 6x4 models.

A ladder type frame, a developed version of the Scammell Contractor, is an all bolted construction. The channel section has a yield strength of 23 tonnes and flitching is included to distribute frame loading where required.

A 24-volt electrical system, including a 128Ah battery, is specified on all models. A 300 litre (75ga1) fuel tank may be supplemented on all models. A 300 litre (75ga1) fuel tank may be supplemented by a second tank on all but the short wheelbase tipper and tractor models.

The £5.5m plant at Wolverhampton is expected to pro'duce around 1000 Landtrains in the first year.