Progress at the Perkins Factory

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

I N the middle of 1033, F. Perkins,

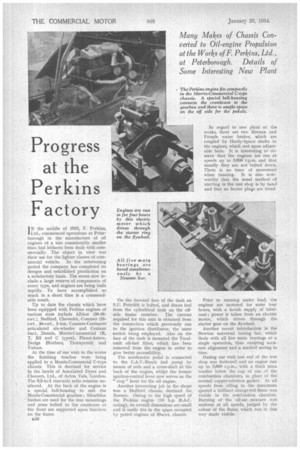

Ltd., commenced operations at Peterborough in the manufacture of oil engines of a size considerably smaller than had hitherto been dealt with commercially. The object in view was their use for the lighter classes of commercial vehicle. In the intervening period the company has completed its designs and established production on a satisfactory basis. The stores now include a large reserve of components of every type, and engines are being built rapidly. To have accomplished so much in a short time is a commendable result.

Up to date the chassis which have been equipped with Perkins engines of various sizes include Albion (30-35cwt.), Bedford, Chevrolet„Commer (25cwt., 30-cwt., 2-ton, Commer-Carrimore articulated six-wheeler and Centaur bus), )Dennis, Morris-Commercial (R, T, RS and C types), Pierce-Arrow, Dodge Mothers, Thornycroft and Vulcan.

At the time of our visit to the works the finishing touches were being "applied to a Morris-Commercial C-type chassis. This is destined for service in the hands of Associated Dyers and Cleaners, Ltd., of Acton Vale, London. The 6.ti-to-1 rear-axle ratio remains unaltered. At the back of the engine is a special bell-housing to suit the Morris-Conlin4cial gearbox ; Silentbloc bushes are used for the rear mountings and arms bolted to the crankcase at the front are supported upon brackets on the frame, a38 On the forward face of the dash an S.U. Petrolift is bolted, and draws fuel from the cylindrical tank on the offside frame member. The current required for this unit is obtained from the connection which previously ran to the ignition distributor, the same switch being employed. Also on the face of the dash is mounted the Tecalemit oil-fuel filter, which has been removed from the engine in order to give better accessibility.

The accelerator pedal is connected to the CA.V.-Bosch fuel pump by means of rods and a cross-shaft at the back of the engine, whilst the former ignition-control lever now serves as the " stop" lever for the oil engine.

Another interesting job in the shops was a Bedford chassis, destined for, Borneo. Owing to the high speed of the Pefkins engine GS h.p. R.A.C. rating), its overall dimensions are small and it easily fits in the space occupied by petrol engines of 30-cwt. chassis. Prior to running under load, the engines are motored for some four hours, with a lavish supply of lubricant; power is taken from an electric motor, which drives through the starter gear on the flywheel.

Another recent introduction is the Newton universal boring bar, which deals with all five main bearings at a single operation, thus ensuring accurate alignment and a marked saving in time.

During our visit one end of the test shop was darkened and an engine run up to 3,600 r.p.m., with a thick mica washer below the cap of one of the combustion chambers, in place of the normal copper-asbestos gasket. At all speeds from idling to the maximum quoted a brilliant orange-red flame was visible in the combustion chamber. Burning of the oil-air mixture was uniform at all speeds, judged by the colour of the flame, which was in this way made visible.