STANDARD 20 SEATERS TO STIMULATE SALES 0 NE of the

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

methods of stimulating demand is to offer immediate or quick delivery. In the private-ear industry this policy has been pursued to an ever-increasing extent.

With passenger vehicles conditions are not the same, but manufacturers, agents and bodybuilders recognize the importance of eliminating the waiting period which is inevitabho when the body has to be built after the chassis has been selected.

Building in readiness for demand must necessarily be confined to those types likely to interest a considerable number of owners in a small way of business. Such a practice would not suit a few large concerns which are in the habit of compiling

a full specification of the bodywork and making their plans, some six months ahead, for renewing or augmenting their fleets.

It is generally agreed that the 20seater is the size of body which makes the best "stock line." As a service bus it usually has a mechanically operated folding door at the front entrance, with an emergency exit at the back. There are five rows of facing-forward seats.

The same framework may be utilized for a coach with a hinged entrance door opening outwards.

B44 Alternatively, a sliding door may be adopted.

As a rule, the height of wheel-arch required is not excessive, but, at the same time, it is large enough to influence the setting out of the crosswise seats. With the normal position of rear axle the third row of seats is placed against the front curve of the wheel-arch and the

fourth row is set back so that a reasonable amount of legroom is provided and the wheel-arch may be used as a foot-rest.

The extra width of the cross gangway between two rows of seats does not entail a greater length of coachwork than is necessary for a body with longitudinal seats over the wheel-arches.

A lengthwise seat for two passengers is about 3 ft. long and a back row of facing-forward seats occupies some 2 ft. 6 ins, of body length, or a total of 5 ft. 6 Ins, from the back of the third row of seats to the back of the body. The last-named dimension is ample for two rows of facingforward seats, even if it includes an enlarged cross gangway.

The length of the driver's compartment is controlled by the length of the steering wheel from the dash. This, in turn, decides how much space remains for the passenger seats within the limit of the 7-24ths maximum legal rear overhang. A few inches may be gained by sloping the lower part of the partition behind the driver, as well as by recessing it at the bottom.

The driver's seat partition is usually in line with the rear pillar of the main entrance. In view of the customary position of the steeringcolumn centre and the need for an offset entrance in the front bulkhead, it is an advantage if the rear pillar of the main entrance be set out a few inches in advance of the driver's seat partition.

The near-side front passenger seat remains in its usual position, consequently there is extra legroom in• front of it and the front end of the central gangway is less obstructed than is the case when there is a continuous front bulkhead.

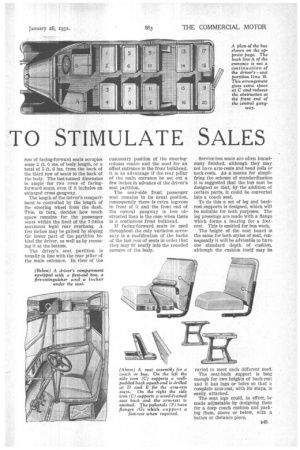

If facing-forwards seats be used throughout the only variation necessary is a modification of the backs of the last row of seats in order that they may fit neatly into the rounded corners of the body. Service-bus seats are often luxuriously finished, although they may not have arm-rests and head rolls or neck-rests. As a means for simplifying the scheme of standardization it is suggested that the bus seat be designed so that, by the addition of certain parts, it could be converted into a coach seat.

To do this a set of leg and backrest supports is designed, which will be suitable for both purposes. The leg pressings are made with a flange which forms a bearing for a footrest. This is omitted for bus work.

The height of the seat board is the same for both styles of seat, consequently it will be advisable to have one standard depth of cushion, although the cushion itself may be varied to meet each different need.

The seat-back support is long enough for two heights of back-rest and it has lugs or holes so that a complete arm-rest, with its stays, is easily attached.

The seat legs could, in effect, be made adjustable by designing them for a deep coach cushion and packing them, above or below, with a batten or distance piece.