A New Design of Petrol Roller

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

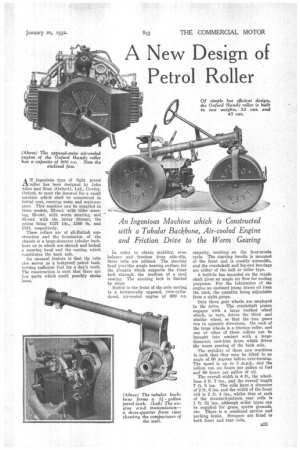

AN ingenious type of light petrol roller has been designed by John Allen and Sons (Oxford), Ltd., Cowley, Oxford, to meet the demand for a small machine which shall be economical in initial cost, running costs and maintenance. This machine can be supplied in three models, 32-cwt. with tiller steering, 32-cwt. with worm steering, and 45-cwt. with the latter fitment, the prices being £157 14s., £169 8s. and f181, respectively.

These rollers are of all-British construction and the foundation of the chassis is a large-diameter tubular backbone on to which are shrunk and locked a steering head and the casting which constitutes the back axle.

An unusual feature is that the tube also serves as a leakproof petrol tank, holding sufficient fuel for a day's work. The construction is such that there are few parts which could possibly shake loose.

• In order to obtain stability, even balance and freedom from side-slip, three rolls are utilized. The steering head provides ample bearing surface for the .kingpin which supports the front fork through the medium of a steel casting. The steering lock is limited by stops.

Bolted to the front of the axle casting is a horizontally opposed, twin-cylin-&red, air-cooled engine of 600 c.c.

capacity, working on the four-stroke cycle. The starting handle is mounted at the front and is readily accessible. and the crankshaft and big-end bearings are either of the ball or roller type.

A built-in fan mounted on the crankshaft gives an ample air flow for cooling purposes. For the lubrication of the engine an enclosed pump draws oil from the tank, the quantity being adjustable from a sight gauge.

Only three gear wheels are employed in the drive. The crankshaft pinion engages with a large toothed wheel which, in turn, drives the third and similar wheel, so that the two, gears run in opposite directions. On each of the large wheels is a friction roller, and one or other of these rollers can ho brought into contact with a largediameter, cast-iron drum whieh drives the worm gearing of the back axle.

The stability of these new machines is such that they may be tilted to an angle of 60 degrees before over-turning. The speed is up to 3 m.p.h., and the rollers run six hours per gallon of fuel and 60 hours per gallon of oil.

The overall width is 4 ft., the wheelbase 4 ft. 7 ins., and the overall length 7 ft. 6 ins. The rolls have a diameter of 2 ft. 6 ins, and the width of the front roll is 2 ft. 4 ins., whilst that of each of the standard-pattern rear rolls is 1 ft. 2i ins., although wider types can be supplied for grass, sports grounds, etc. There is a combined service and parking brake. Scrapers are fitted to both front and rear rolLs.