Coal Fuel for Internal-combustion Engines.,

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

An Ingenious Engine of which a Producer forms an Integral Part.

A representative of our sister journal, " The Motor," has recently had the good fortune to investigate the claims of an inventor, Mr. A. M. Low, of the British Low Accessories Co., Ltd., of 15, Great St. Helen's, E.C., who has introduced entirely-revolutionary ideas into the design of an internal-combustion engine. An experimental motor has been made, and the results obtained are stated to be very promising ; there can be no doubt that the experience gained by the inventor with this experimental set will enable him to design and produce a highly-etheient power unit. Whether it will ever be practically applied to motor vehicles, however, is a question as to which we hold an open mind. The idea of using common house veal as a fuel tor internal-combustion engines is certainty alluring, but, unless such an engine can show much-better economy and higher thermal efficiency than is now obtained with petrol motors, we doubt whether it will ever be used on a large scale. Mr. Low's engine is undoubtedly more complicated in construction than is the ordinary form of petrol motor. lit Mr. Low's engine, ordinary bituminous mal, broken up Mtn very-small pieces, is placed in a coal box, and is

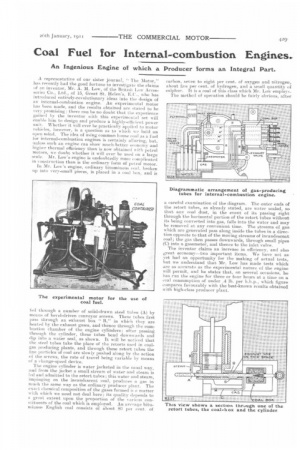

fed through a number of solid-drawn steel tithes (A) by means of bevel-driven conveyor screws. These tubes first pass through an exhaust box " B," in which they are heated by the exhaust gases, and thence through the comr bustion chamber of the engine cylinders ; after passing through the cylinder, these tubes bend downwards and (lip into a water seal, as shown. It will he noticed that the steel tubes take the place of the retorts used in coalgas producing plants, and through these retort tubes the line particles of coal are slowly pushed along by the action of the screws, the rate of travel being variable by means of a change-speed device.

The engine cylinder is water jacketed in the usual way, and from the jacket a small stream of water and steam is led and admitted to the retort tubes; this water and steam, impinging on the incandescent coal, produces a gas in much the same way as the ordinary producer plant. The exact chemical composition of the gases formed is a matter with which we need not deal here; its quality depends to a great extent upon the proportion of the various constiteents of the coal which is employed. An average bituminous English coal consists of about 80 per cent, of carbon, seven to eight per cent. of oxygen and nitrogen, about five per cent, of hydrogen, and a small quantity of sulphur. It is a coal of this class which Mr. Low employs_ The method of operation should be fairly obvious, after

a careful examination of the diagram. The outer ends of the retort tubes, as already stated, are water sealed, so that any coal dust, in the event of its passing right through the horizontal portion of the retort tubes without its being converted into gas, falls into the water and may be removed at any convenient time. The streams of gas which are generated pass along inside the tubes in a direction opposite to that of the moving streams of incandescent coal ; the gas then passes downwards, through small pipes. (C) into a gasometer, and thence to the inlet valve.

The inventor claims an increase in efficiency, and also, great economy—two importantitems. We have not as: yet had an opportunity for the making of actual tests,. but we understand that Mr. Low has made tests which are as accurate as the experimental nature of the engine will permit, and he states that, on several occasions, he has run the engine for three or four hours at a time on a coal consumption of under .4 lb. per b.h.p., which figure compares favourably with the best-known results obtained with high-class producer plant.