SPECIALIZATION

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

in

CHASSIS LUBRICATION.

• TN thew days the tendency in all ..1directions is to reduce the time and effort necessary to carry out routine operations. Lubrication of machinery falls into this category and that of the motor vehicle particularly so, in that a little oil or grease is usually needed daily, weekly or monthly, according to the parts concerned. When a motor is used for industrial purposes the spare time available is generally strictly one of the most widely known. A recent call at the factory revealed intense activity: an instance of this is that about 750,000 grease-gun nipples are turned out per month.

In view of the fact that attention is now being focused upon systems of central lubrication for the chassis parts, the Temlemit design is a noteworthy item in the wide range of products marketed by the concern in question.

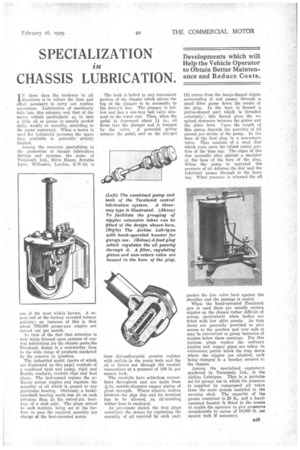

The industrial model (parts of which are illustrated on this page) consists of a combined tank and pump, rigid and flexible conduits, conduit clips and feed plugs. The last-named replace the ordinary grease nipples and regulate the quantity of oil which is passed to any particular bearing. Obviously a brakecamshaft bearing needs less oil on each occasion than do the swivel-pin bearings of a stub axle. The plugs attend to such matt6rs, being set at the factory to pass the required quantity per charge of the heel-operated pump. : '.11e tank is bolted to any convenient portion of the chassis which allows the top of the plunger to be accessible to the driver's feet. The plunger is.hollow and has a one-way, ball valve situated in the lower end. Thus, when the Pedal is depreSsed about 1f in., oil flows into the plunger and is trapped by the valve. A powerful spring returns the pedal, and as the plunger (Left) The combined pump and tank of the Tecaferrat central lubrication system. A threeway type is illustrated. (Above) To facilitate the grouping of nipples extension tubes can be fitted of the design shown here. (Right) The Airline Lubrigun with hand-operated booster for garage use. (Below) A feed plug which regulates the oil passing through it. A filter, regulating piston and non-return valve are housed in the bore of the plug.

rises circumferential grooves register with outlets in the pump body and the oil is forced out through the conduit connections at a pressure of 100 lb. per square inch.

The conduits have solclerless connections throughout and are made from outside-diameter copper piping of great strength. Where relative motion between the pipe line and its terminal has to be allowed, an oil-resisting rubber hose is employed.

As previously stated. the feed plugs constitute the means for regulating the quantity of oil receivea by each part.

Oil enters from the banjo-shaped nipple surrounding it and passes through a small filter gauze down the centre of the plug. In the bore is housed a piston-shaped part which is threaded externally ; this thread gives the required clearance between the piston and the plain bore. Upon the length of this piston depends the quantity of oil passed per stroke of the pump. In the base of the feed plug is a non-return valve. This consists a a steel disc which rests upon the raised centre portion of the base can. The edges of the disc normally abut against a shoulder at the base of the bore of the plug. When the pump is operated the pressure of oil deforms the disc and the lubricant passes through to the bearing. When pressure is released the oil

pushes the disc valve back against the shoulder and the passage is sealed. When the hand-operated Tecalemit gun is used there are usually certain nipples on the chassis rather difficult of access, particularly when bodies are fitted with low skirt panels. As trap doors are generally provided to give access to the gearbox and rear axle it may be convenient to group batteries of nipples below these openings. For this purpose plugs replace the ordinary nipples and copper pipes are taken to convenient points below the trap doors . where the nipples are situated, each being clamped in a bracket secured to the chassis.

Among the specialized equipment marketed by Tecalemit, Ltd., is the Airline Lubrigun. . This is a portable set for garage use in which the pressure is supplied by compressed air taken from the main system installed in the running shed. The capacity of the grease container is 25 lb., and a handoperated booster is fitted to the nozzle to enable the operator to give pressures considerably in excess of 10,000 lb. per square inch if necessary.