A STRAIGHT-EIGHT BUS CHASSIS.

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

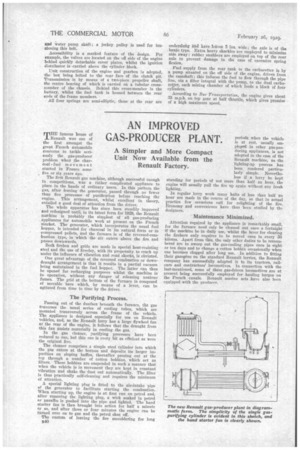

A New Studebaker Model for High-speed Passenger Work Claimed to be the Pioneer of its Type in America.

(\NE of the latest introductions of the Studebaker IL/Corporation of America is a chassis designed for highsPeed passenger vehicles, with an all-in-line eight-cylindered engine which gives 115 b.h.p. There are three standard types marketed, namely, two with 15-ft. 4-in. wheelbases, having either a three or four-speed gearbex, and the shorter chassis of 13-ft. 2-in. 'wheelbase with a three-speed gearbox.' The increase in length of the bonnet by reason of the addition of two more cylinders is only 41 ins., as compared with the former six-cylinder chassis, but the gain in power' is some 20 per cent., whilst the additional weight of the chassis is under 100 lb. The fuel consumption is stated to be the same as that of its six-cylindered prototype.

The engine is of the L-head pattern with a detachable cylinder head and fully machined combustion chambers ; the bore is 3i ins., the stroke 4i ins., and the capacity 5,522 c.c.; it can attain 3,200 r.p.m. The pistons are of aluminium alloy and have split skirts. Bach is fitted with four rings. The hearings are without shims and the anti friction metal is poured directly into the connectbig rod ends and caps. The crankshaft is balanced statically and dynamically and rims in five large main bearings, which are bronze-backed. The crankshaft is drilled to provide oil passages and the camshaft runs in six bearings.

Full-pressure lubrication is employed to the main, big-end and camshaft bearings, and there are passages up the connecting rods which allow oil to squirt on to the cylinder walls at each revolution.

A duplex type of Stromberg carburetter supplies the mixture through a manifold which incorporates a heating device controlled from the dash. A special spring-loaded choke prevents crankcase oil dilution in ease the driver has to resort to an unduly strong mixture for starting from cold. '

Following conventional practice, the starter is DOW mounted at the rear of the engine, operating upon a toothed ring on the flywheel. Cooling is aided by a 21-in fan driven by a 2-in, flat belt, which also drives the dynamo

and water pump shaft; a jockey pulley is used for tensioning this belt.

Accessibility is a marked feature of the design. For example, the valves are located on the off side of the engine behind quickly detachable cover plates, whilst the ignition distributor is carried above the cylinder block.

Unit construction of the engine and gearbox is adopted, the box being bolted to the rear face of the clutch pit. Transmission is by means of a two-piece propeller shaft, the centre bearing of which is carried on a tubular crossmember of the chassis. Behind this cross-member is the battery, whilst the fuel tank is housed between the rear ends of the frame members.

All four springs are semi-elliptic, those at the rear are underslung find have leaves 3 ins, wide; the axle is of the banjo type. Extra heavy shackles are employed to minimize side sway ; rubber snubbers are employed on top of the rear axle to prevent damage in the case of excessive spring flexion.

Fuel supply from the rear tank to the carburetter is by a pump situated on the off side of the engine, driven from the camshaft ; this induces the fuel to flow through the pipe line, via a filter integral with the pump, to the dual carburetter, each mixing chamber of which feeds a block of four cylinders.

According to Bus Transportation, the engine gives about 35 m.p.h. on top gear at half throttle, which gives promise of a high maximum speed.